Method for low-temperature preparation of cubic silicon carbide nano wire

A cubic silicon carbide and nanowire technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve problems such as large-scale preparation that have not been realized, and achieve good product morphology, simple and easy-to-control operation, and low reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Low-temperature synthesis of cubic silicon carbide nanowires

[0033] Take 1.0g of silicon powder, 4.0g of sodium metal, 3mL of tetrachlorethylene and 1g of sulfur powder, and put them into a special stainless steel reaction kettle (the volume of the reaction kettle is 25ml). In a drying oven, react for 40 hours at 120°C (furnace temperature controlled at ±1°C) and 6.8MPa; after stopping heating, cool the reaction kettle to room temperature naturally; open the kettle, wash the obtained product with 95% ethanol, Wash with 1mol / L hydrochloric acid, then wash with 70% perchloric acid by weight percentage, wash with nitric acid:hydrofluoric acid=1:1 mixture, wash with carbon disulfide, wash with water until pH neutral, centrifuge and vacuum at 50°C After drying for 6 hours, an off-white powder product, namely cubic silicon carbide (3C-SiC) powder, was finally obtained.

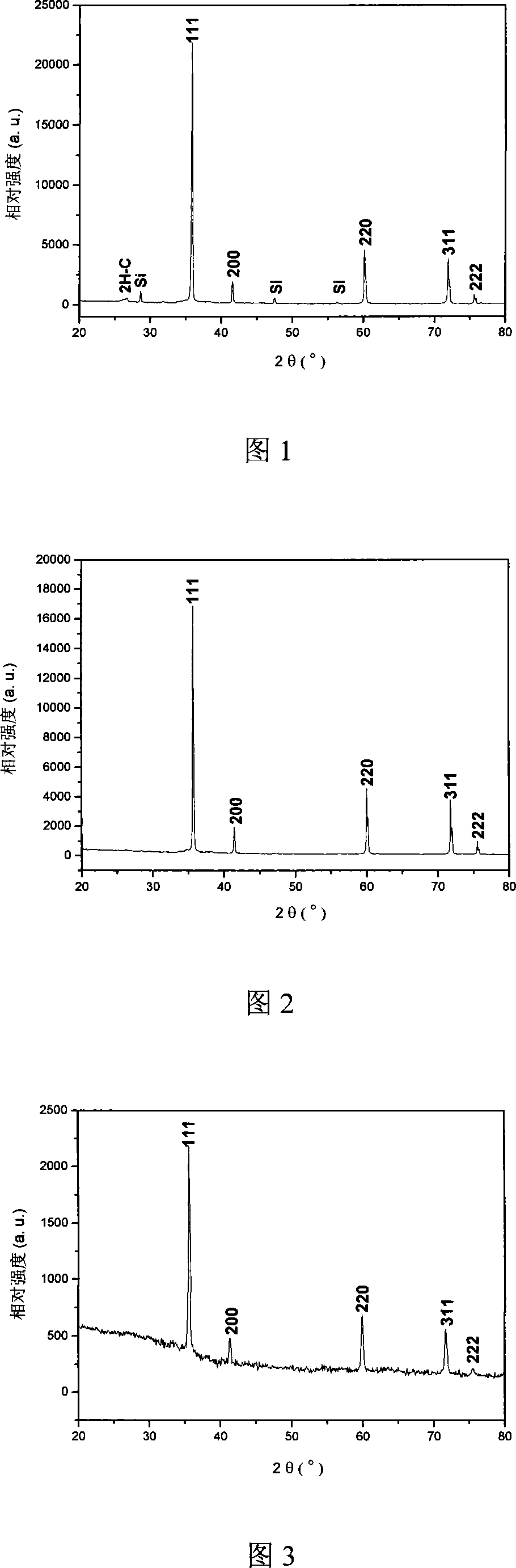

[0034] The crop phase of the product was analyzed using a German Bruker D8 ADVANCE X-ray pow...

Embodiment 2

[0041] Example 2: Low-temperature synthesis of cubic silicon carbide nanowires

[0042] Take 1.0g of silicon powder, 4.0g of sodium metal and 3mL of tetrachlorethylene, put them into a special stainless steel reaction kettle (the volume of the reaction kettle is 25ml), use nitrogen to remove the air in the kettle, seal it and place it in an electric heating constant temperature blast drying box, React at 260°C (furnace temperature controlled at ±1°C) and 8.7MPa for 20 hours; after stopping heating, cool the reactor to room temperature naturally; Washing, then washing with 70% perchloric acid by weight percentage, washing with nitric acid: hydrofluoric acid = 1: 1 mixed solution, washing with water until the pH is neutral, centrifuging and vacuum drying at 50°C for 6 hours, finally obtaining off-white Powder products, namely 3C-SiC powder.

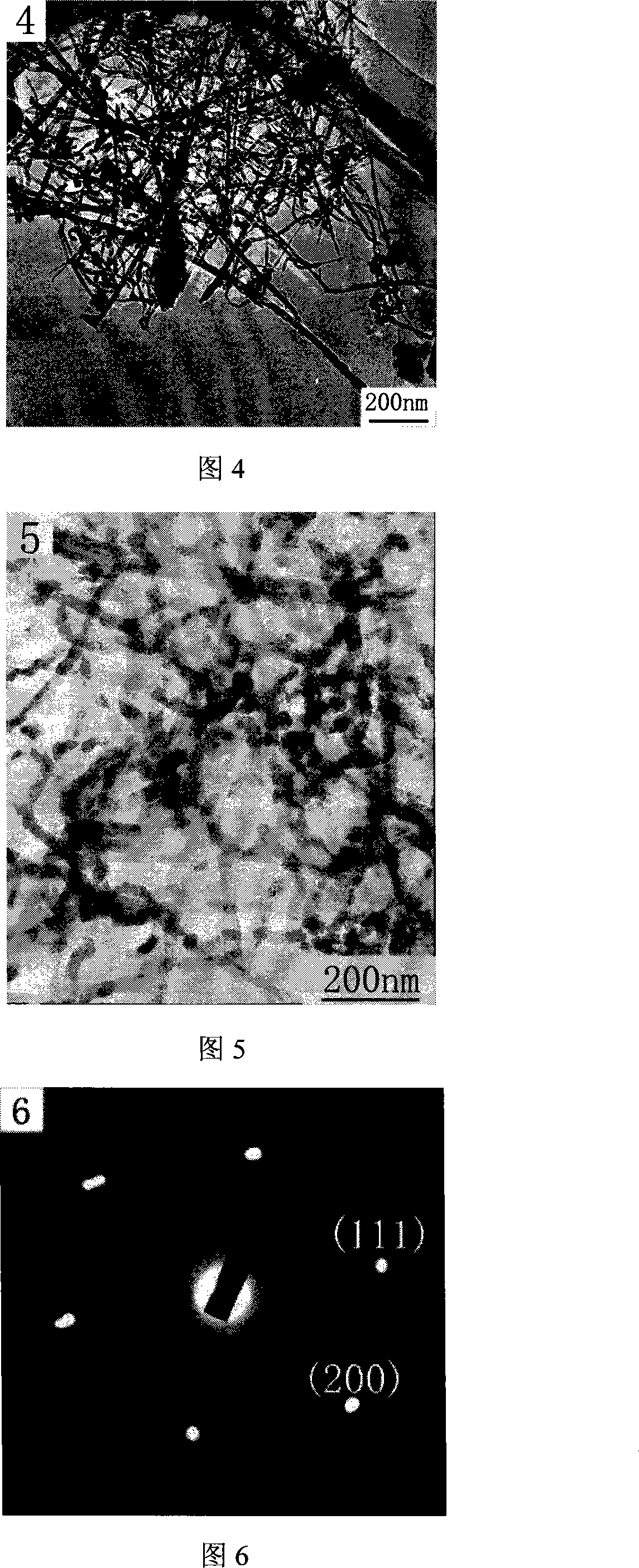

[0043] Fig. 8 is the X-ray powder diffraction spectrum of the purified product prepared by using silicon powder, sodium metal and tetrach...

Embodiment 3

[0046] Example 3: Low-temperature synthesis of cubic silicon carbide nanowires

[0047] Mix silicon powder, tetrachlorethylene, sodium metal and sublimed sulfur in a molar ratio of 0.5:1:2:0.5, seal in an autoclave, and react at 160°C and 10MPa for 35 hours; the product is washed with ethanol, sulfuric acid, Washing with water until the pH is neutral, conventional centrifugation, and drying to obtain cubic silicon carbide nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com