GaN blue light LED device using 3C-SiC-Si as substrate

An LED device, 3c-sic-si technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high price, high crystallization temperature, reduce the area of die light, and reduce production costs and processing. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

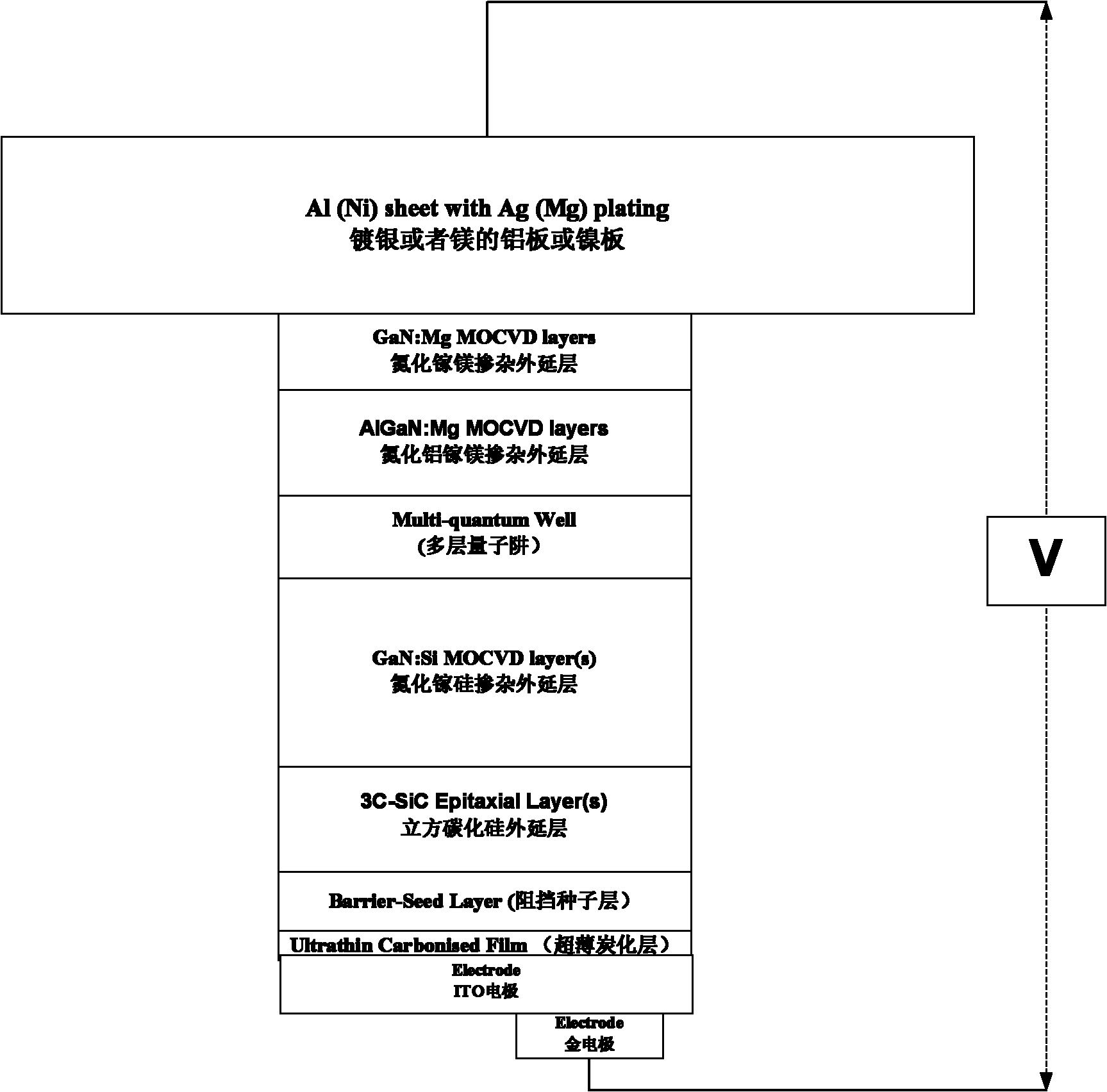

[0023] The structure and manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings.

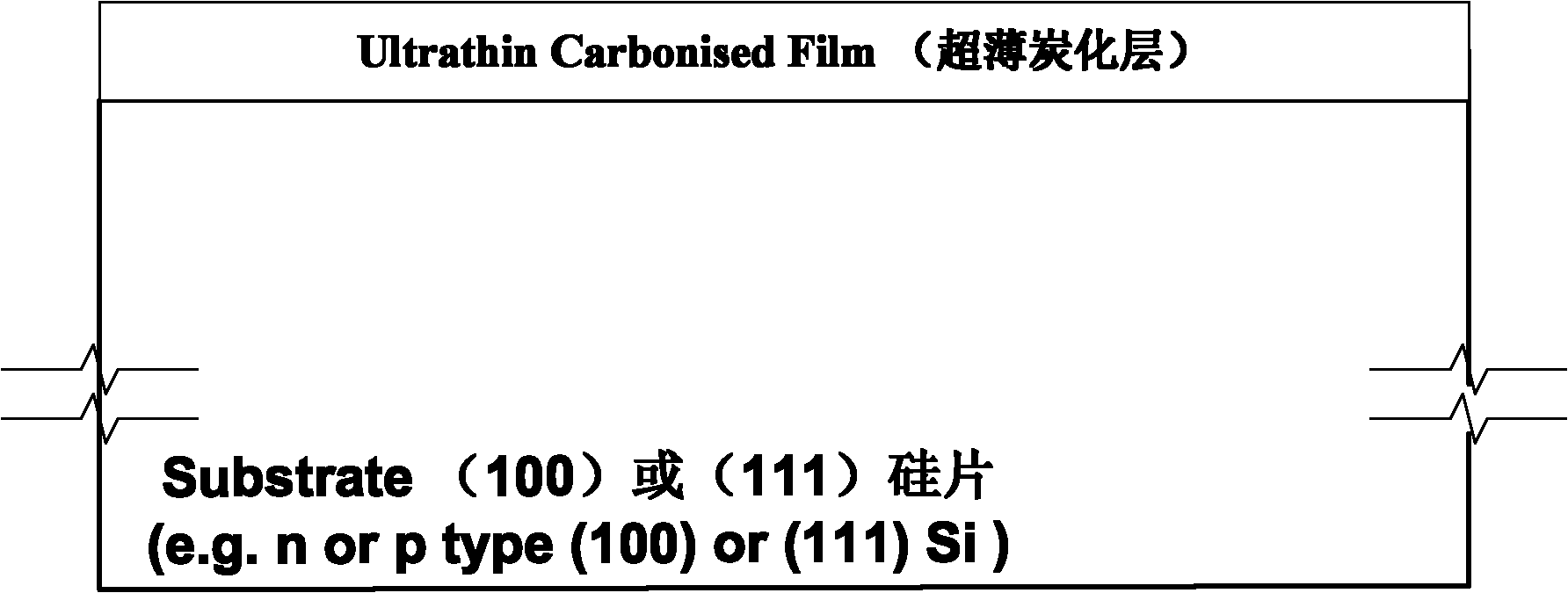

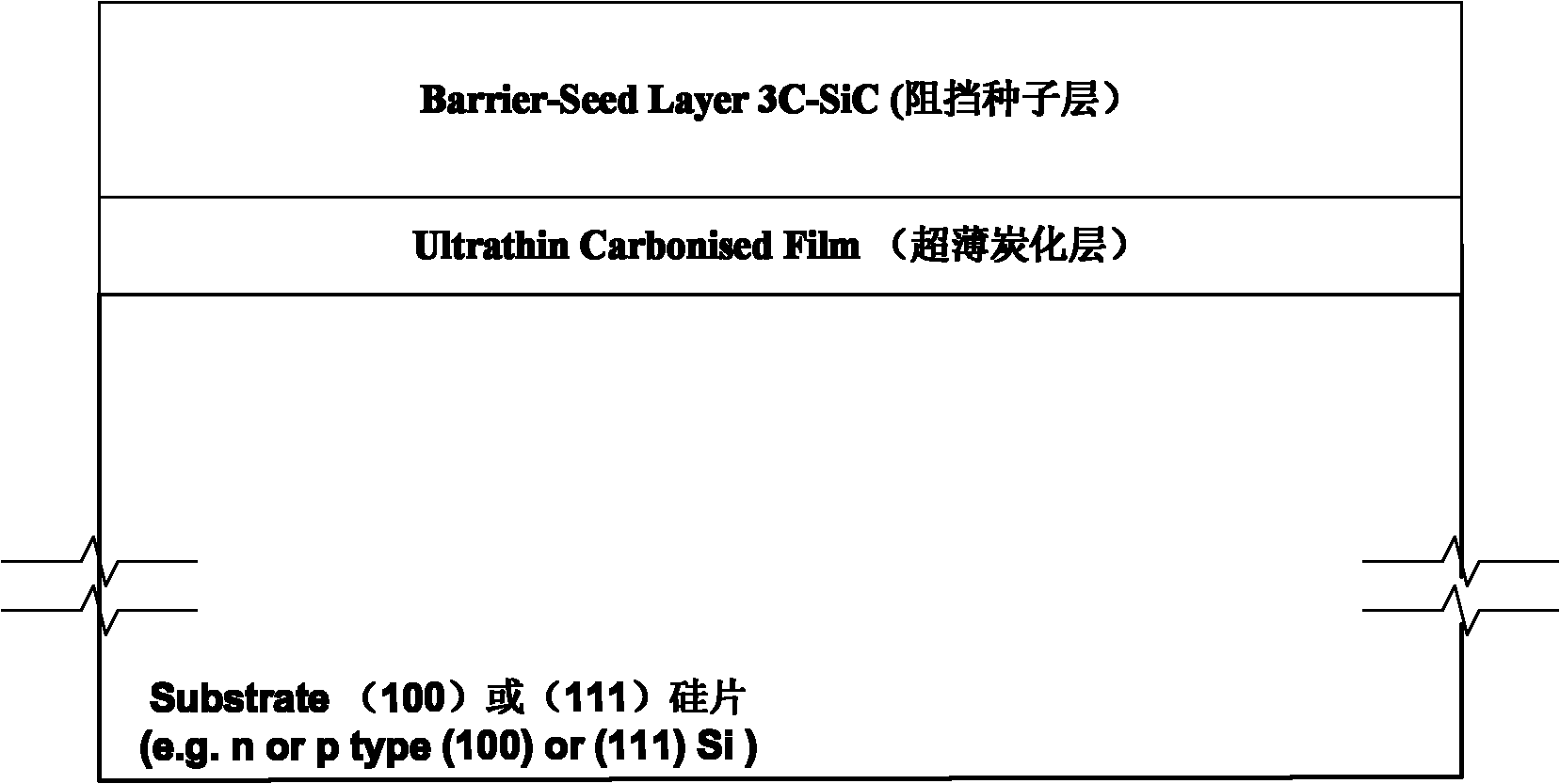

[0024] Referring to the accompanying drawings, the GaN blue LED device based on 3C-SiC-Si according to the present invention includes a base substrate layer, a buffer layer and a GaN structure layer from bottom to top, wherein the base substrate layer is made of silicon with a diameter of 50 mm to 300 mm. The buffer layer is a cubic silicon carbide epitaxial layer epitaxially grown on the silicon wafer, and the GaN structure layer is a GaN deposition layer epitaxially grown on the buffer layer.

[0025] A specific fabrication example of the method for fabricating the GaN blue LED device is as follows. This embodiment is a process step of manufacturing a GaN blue light LED device based on a six-inch silicon wafer.

[0026] In the first step, a six-inch n-type silicon wafer with a (111) crystal plane is selected as the basic sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com