Method for preparing cubic silicon carbide ultrafine powder by using waste plastic at low temperature

A technology of cubic silicon carbide and ultrafine powder, applied in chemical instruments and methods, polycrystalline material growth, crystal growth, etc., to achieve the effect of easy industrial production and environmentally friendly industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Collect used plastic waste whose main components are high-density polyethylene (HDPE), low-density polyethylene (LDPE) or polyethylene terephthalate (PET), wash it with water and dry it naturally. Or dry at 60°C for 3 hours, and finally shred or mechanically pulverize for use.

[0016] A method for preparing cubic silicon carbide superfine powder at low temperature, the steps are as follows:

[0017] (1) Molar ratio (0.1-3): 1: (0.5-8): (0.2-3.2): ( 0.1-3) mixing, sealing in a stainless steel autoclave, placing the autoclave in a resistance furnace, and reacting for 10-30 hours at 350-500°C and 0.5-10MPa;

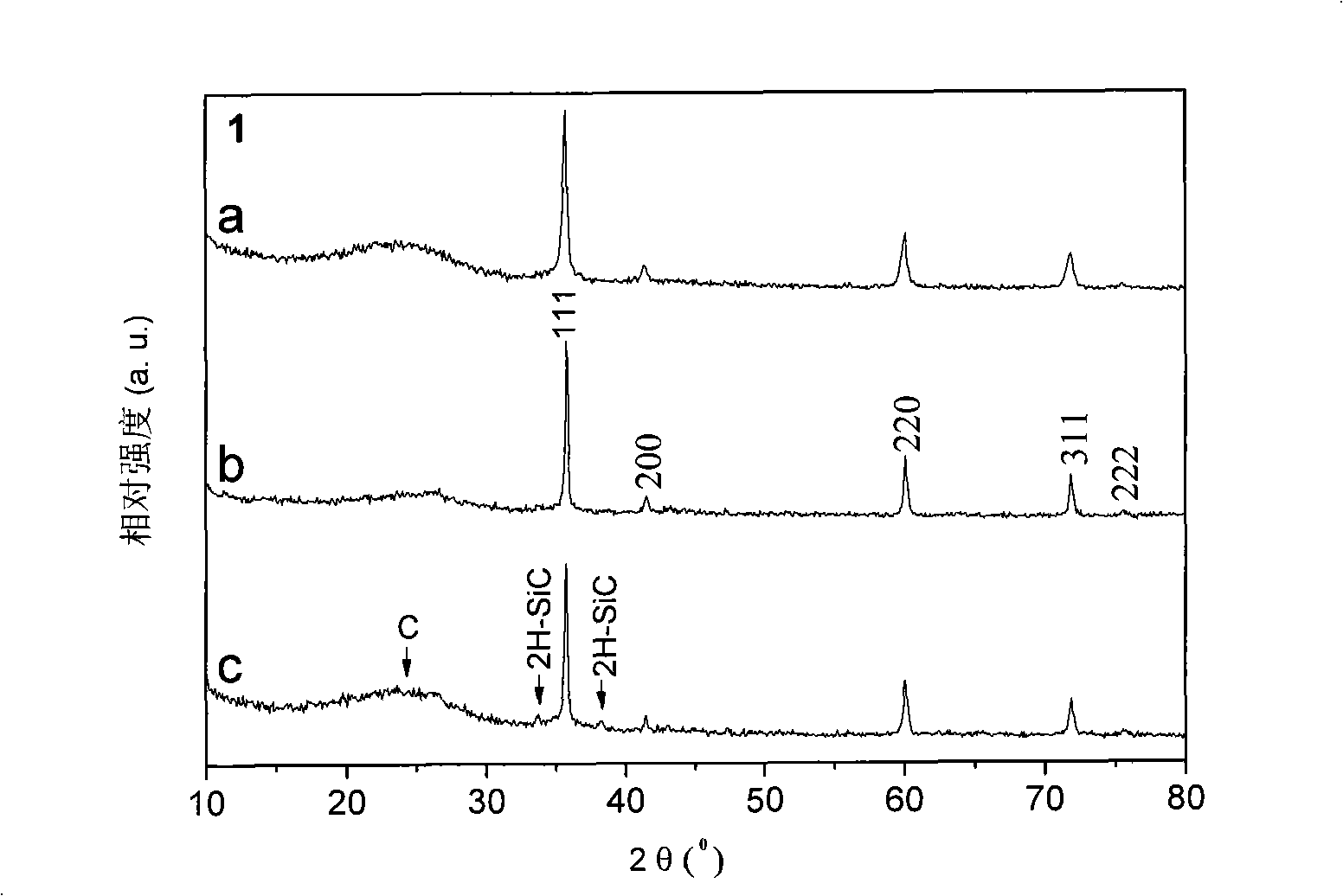

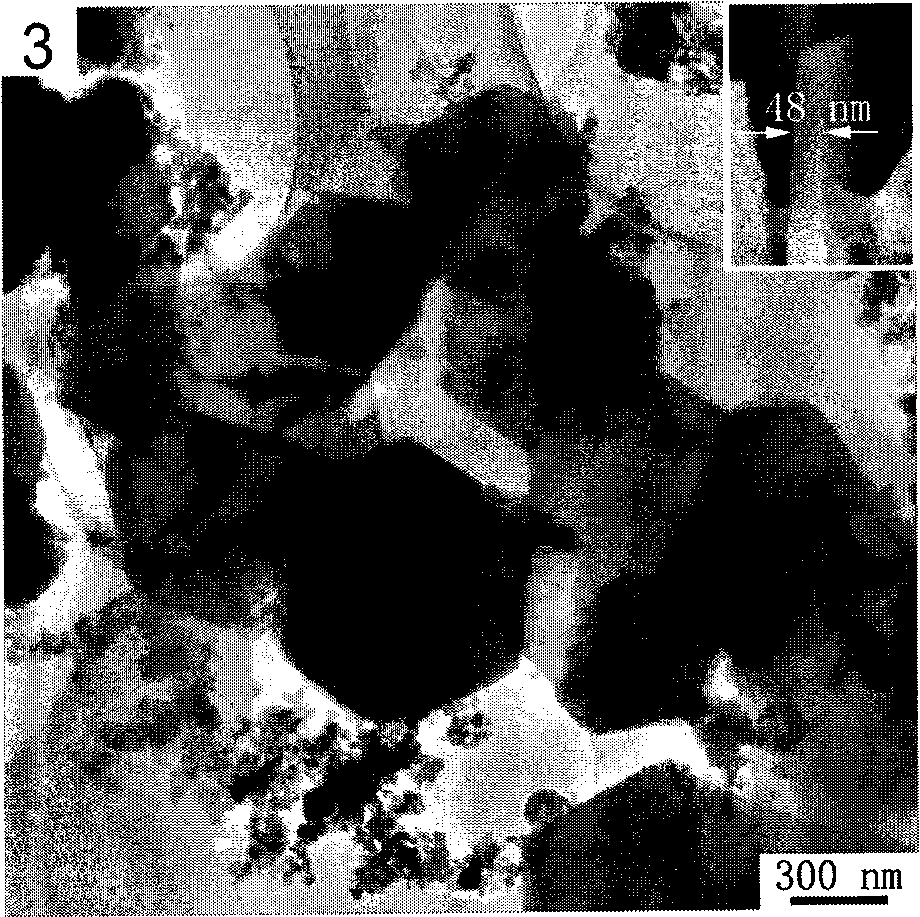

[0018] (2) The product obtained in step (1) is washed with alcohol, washed with water, and conventionally centrifuged, and dried to obtain a crude cubic silicon carbide containing a small amount of silicon powder and amorphous carbon, see figure 1 The X-ray diffraction spectrum.

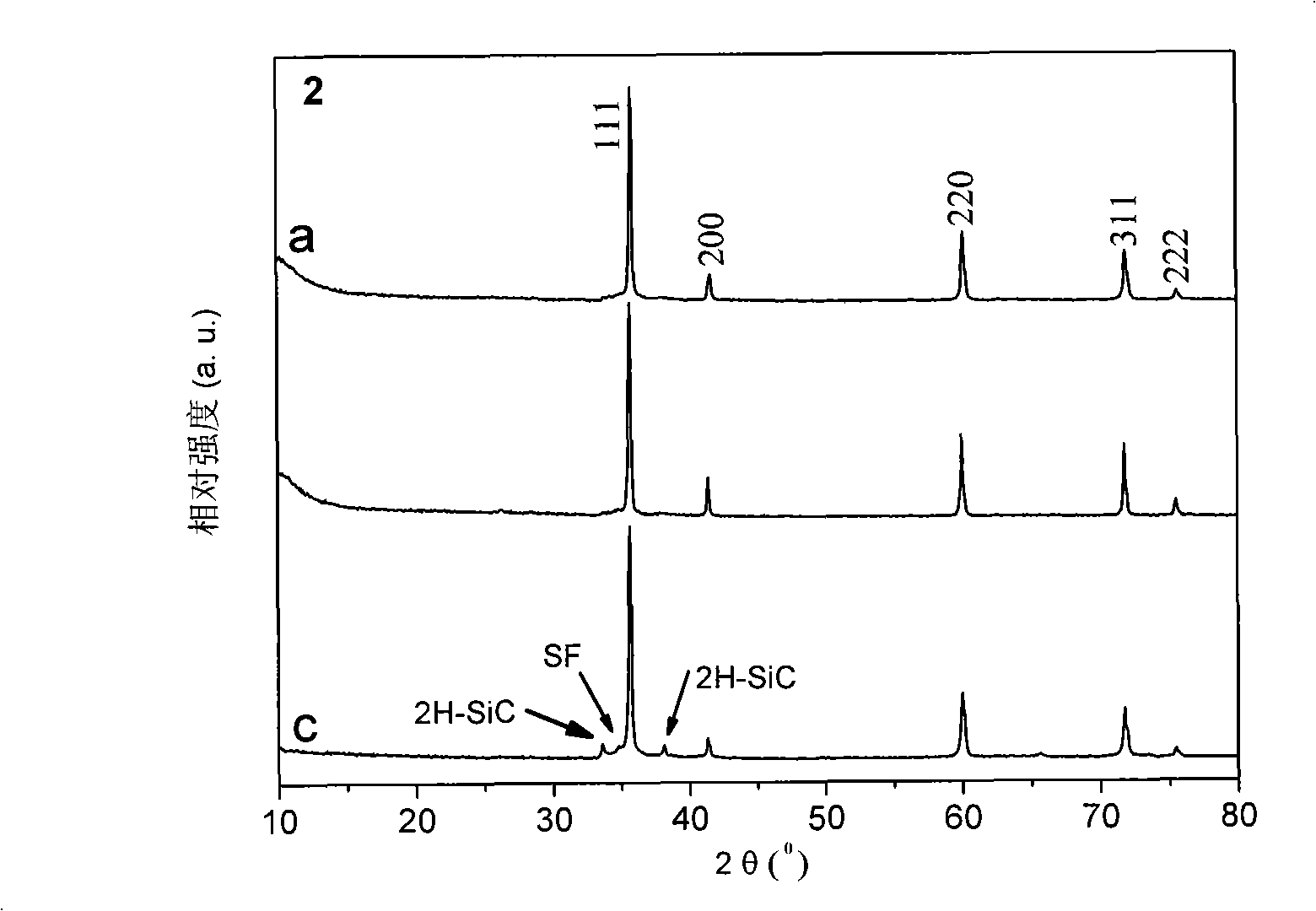

[0019] (3) The product obtained in step (2) is refluxed with 70%wt perchloric acid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com