Fluorinated graphene electrode material and preparation method thereof

A technology of fluorinated graphene and electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of immature preparation technology of fluorinated graphene and few researches on fluorinated graphene, and achieve low preparation cost, The preparation process is simple, the effect of high voltage platform and specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

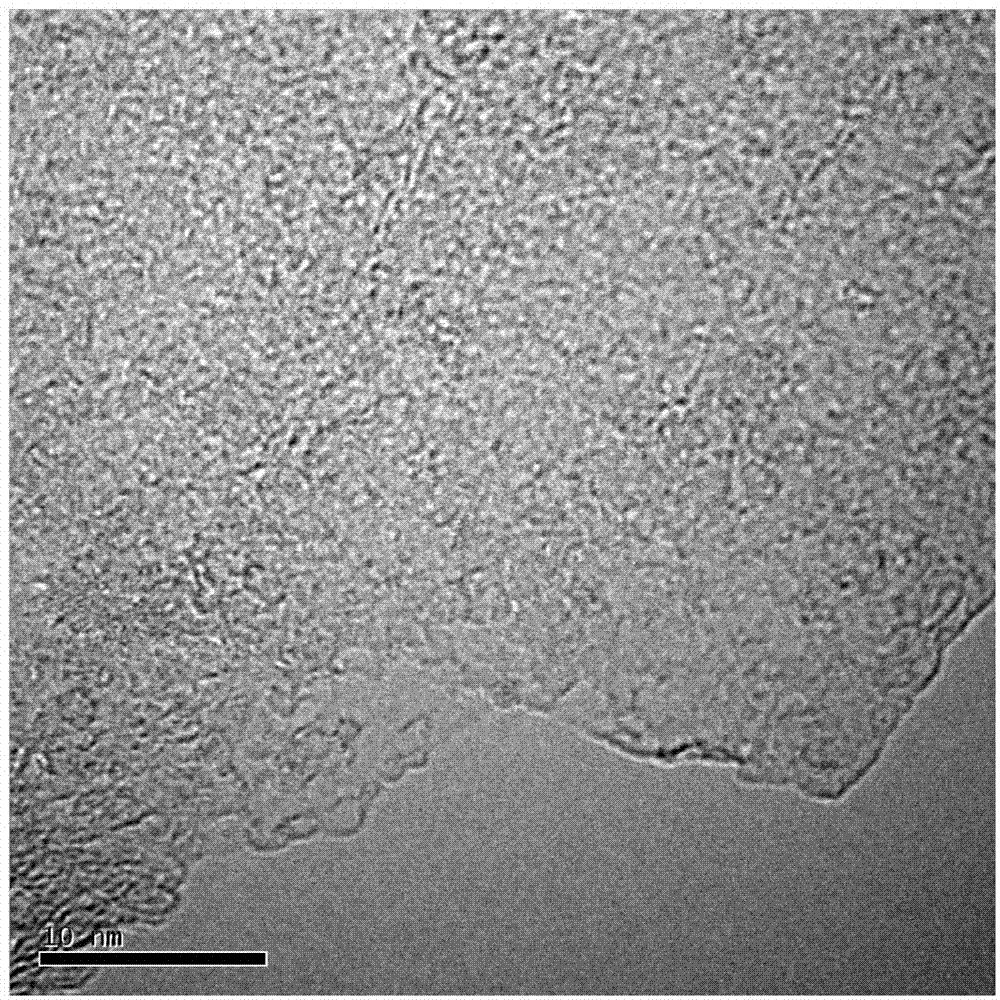

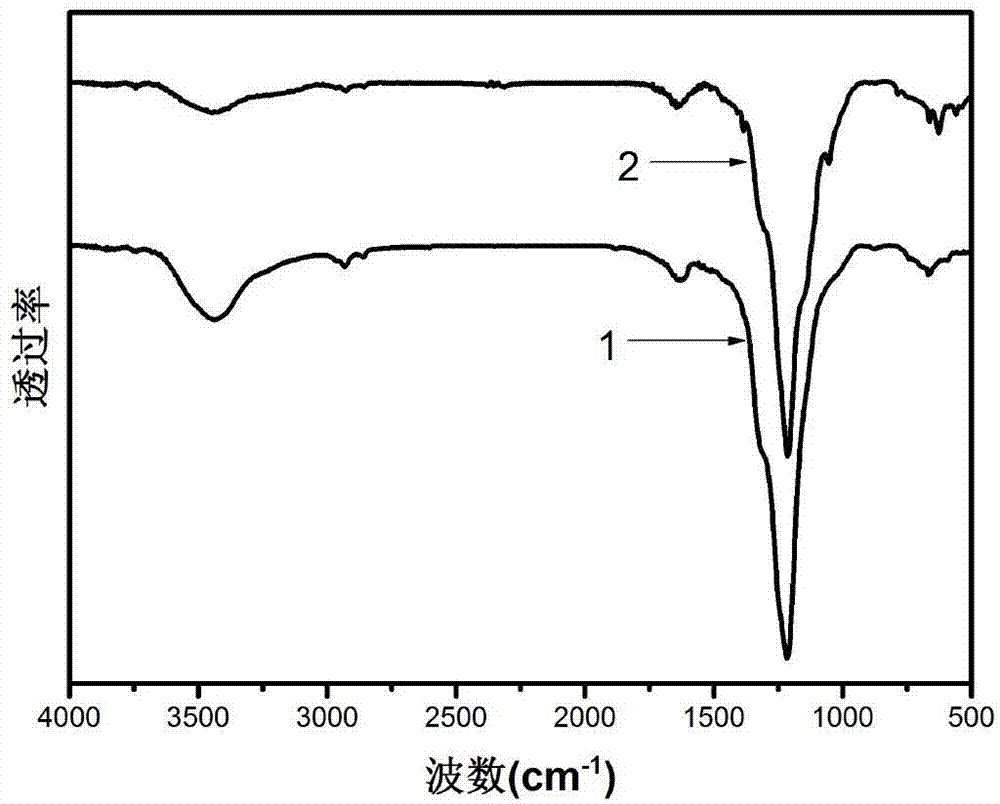

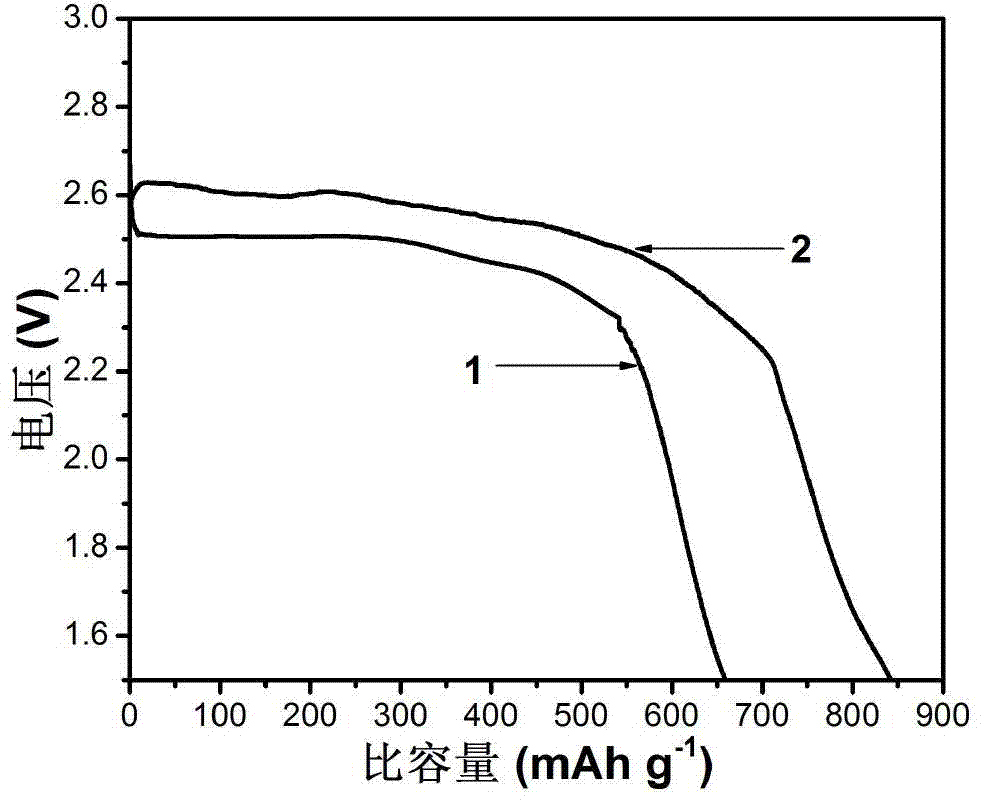

[0020] Weigh 20 mg of fluorinated graphite and add it to 100 mL of tetrahydrofuran, stir at a constant speed for half an hour to disperse the fluorinated graphite in acetone, then add it to a stainless steel reaction kettle, put the reaction kettle into a muffle furnace, and heat at 60°C for 12 hours. After the end, the obtained suspension was ultrasonicated for 6 hours, and then the ultrasonicated suspension was centrifuged at a speed of 500r / min for 30 minutes to remove the lower solid, and the obtained solution was suction filtered to obtain a filter cake, which was dried at 60°C , to obtain fluorinated graphene materials. Weigh a certain proportion of fluorinated graphene, acetylene black, PVDF solution (dissolved in NMP, mass fraction 10%), fluorinated graphene, acetylene black, polyvinylidene fluoride mass ratio is 80:10:10, and then It was ground in a mortar and 2ml of NMP was added dropwise. Spread the ground slurry evenly on the aluminum foil, place it in a blast ove...

Embodiment 2

[0022]Weigh 50 mg of fluorinated graphite and add it to 100 mL of acetone, stir at a constant speed for half an hour to disperse the fluorinated graphite in acetone, then add it into a stainless steel reaction kettle, heat at 80°C for 10 h, after the heating time is over, ultrasonicate the obtained suspension for 8 h, Then the supersonicated suspension was centrifuged at 1000r / min for 30min to remove the solids in the lower layer, and the resulting solution was suction-filtered to obtain a filter cake, which was dried at 60°C to obtain a fluorinated graphene material. Weigh a certain proportion of fluorinated graphene, acetylene black, PVDF solution (dissolved in NMP, mass fraction 10%), fluorinated graphene, acetylene black, polyvinylidene fluoride mass ratio is 75:15:10, and then It was ground in a mortar and 2ml of NMP was added dropwise. Spread the ground slurry evenly on the aluminum foil, place it in a blast oven and bake at a certain temperature for 1-2 hours. The bake...

Embodiment 3

[0024] Weigh 60 mg of fluorinated graphite and add it to 100 mL of isopropanol, stir at a constant speed for half an hour to disperse the fluorinated graphite in acetone, then add it into a stainless steel reaction kettle, put the reaction kettle into a muffle furnace, and heat at 100°C for 12 hours. After the heating time is over, ultrasonicate the obtained suspension for 10 h, then centrifuge the ultrasonicated suspension at a speed of 1500 r / min for 20 min to remove the lower layer of solids, filter the obtained solution with suction to obtain a filter cake, and filter the filter cake at 60 °C Dry to obtain the fluorinated graphene material. Weigh a certain proportion of fluorinated graphene, acetylene black, PVDF solution (dissolved in NMP, mass fraction 10%), fluorinated graphene, acetylene black, polyvinylidene fluoride mass ratio is 82:8:10, and then It was ground in a mortar and 2ml of NMP was added dropwise. Spread the ground slurry evenly on the aluminum foil, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com