Graphene, graphene electrode, graphene supercapacitor and preparation method thereof

A graphene electrode and supercapacitor technology, which is applied to the preparation of electronic components, the preparation of graphene electrodes and graphene supercapacitors, and the field of graphene, can solve problems such as high cost, high energy consumption, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

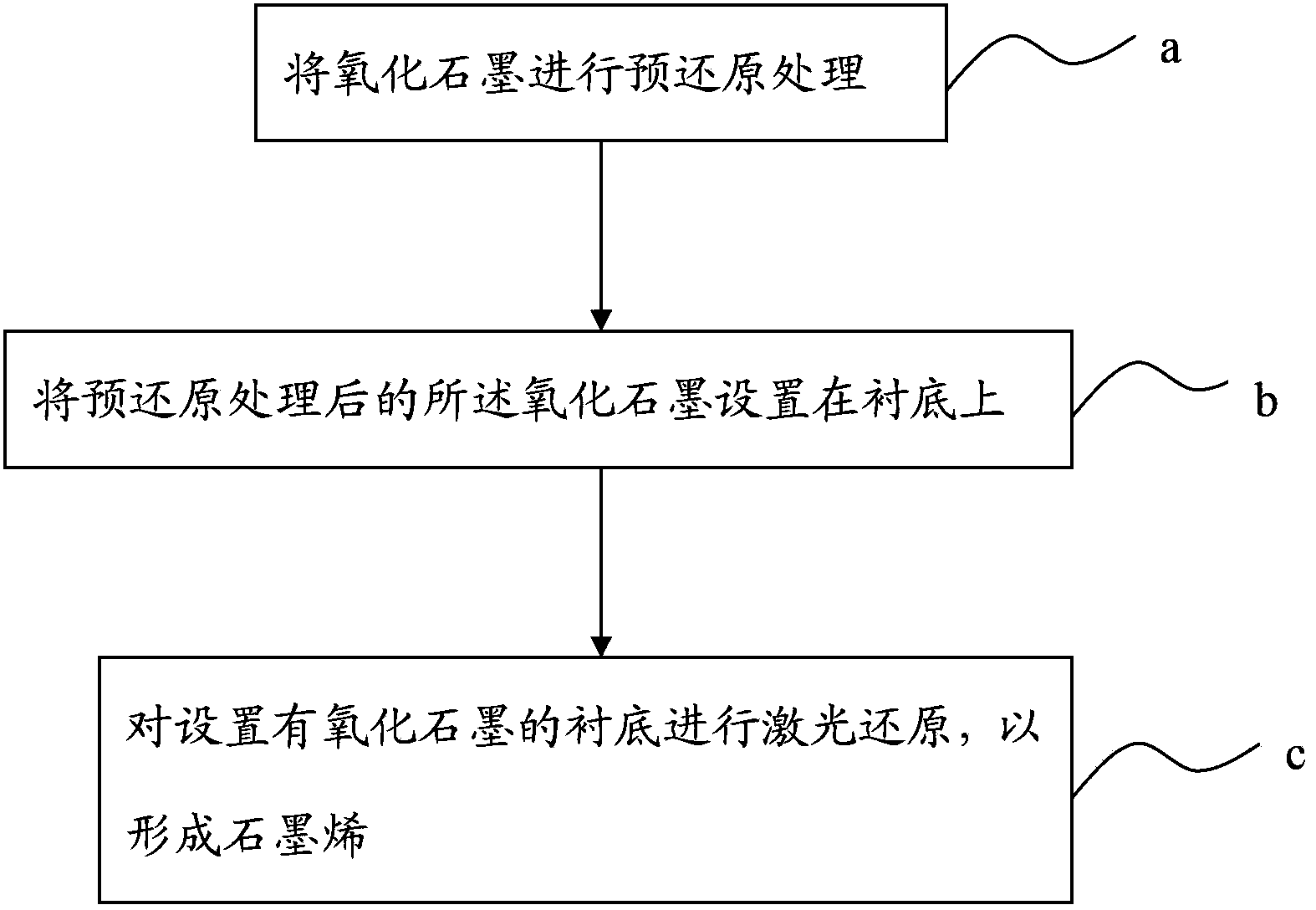

[0040] Such as figure 1 Shown, the preparation method according to the graphene of the embodiment of the present invention comprises the following steps:

[0041] a) Pre-reduction treatment of graphite oxide (step a)

[0042] Regarding the method of pre-reducing the graphite oxide, for example, laser reduction, chemical reduction and the like can be used.

[0043] In some embodiments of the present invention, the graphite oxide and pre-reducing agent water (for example, deionized water) are configured into a mixed liquid, so as to pre-reduce the graphite oxide.

[0044] Wherein, the graphite oxide may be a commercially available aqueous dispersion of graphite oxide, of course, it may also be prepared according to a conventional preparation method.

[0045]The amount of the pre-reducing agent is designed according to the content of the graphite oxide, for example, the mass ratio of the pre-reducing agent to the graphite oxide may be pre-reducing agent:graphite oxide=0.1-0.75....

Embodiment 1

[0081] First, prepare a mixture of graphite oxide / vitamin C (pre-reducing agent). Among them, in the mixed solution, the mass ratio of vitamin C to graphite oxide is 1:3. And relative to graphite oxide, add 2wt% dispersant.

[0082] Next, the mixed solution was ultrasonically dispersed for 2 minutes, the mixed solution was coated on a PET film with a thickness of 180 um, and dried naturally at room temperature for 15 hours.

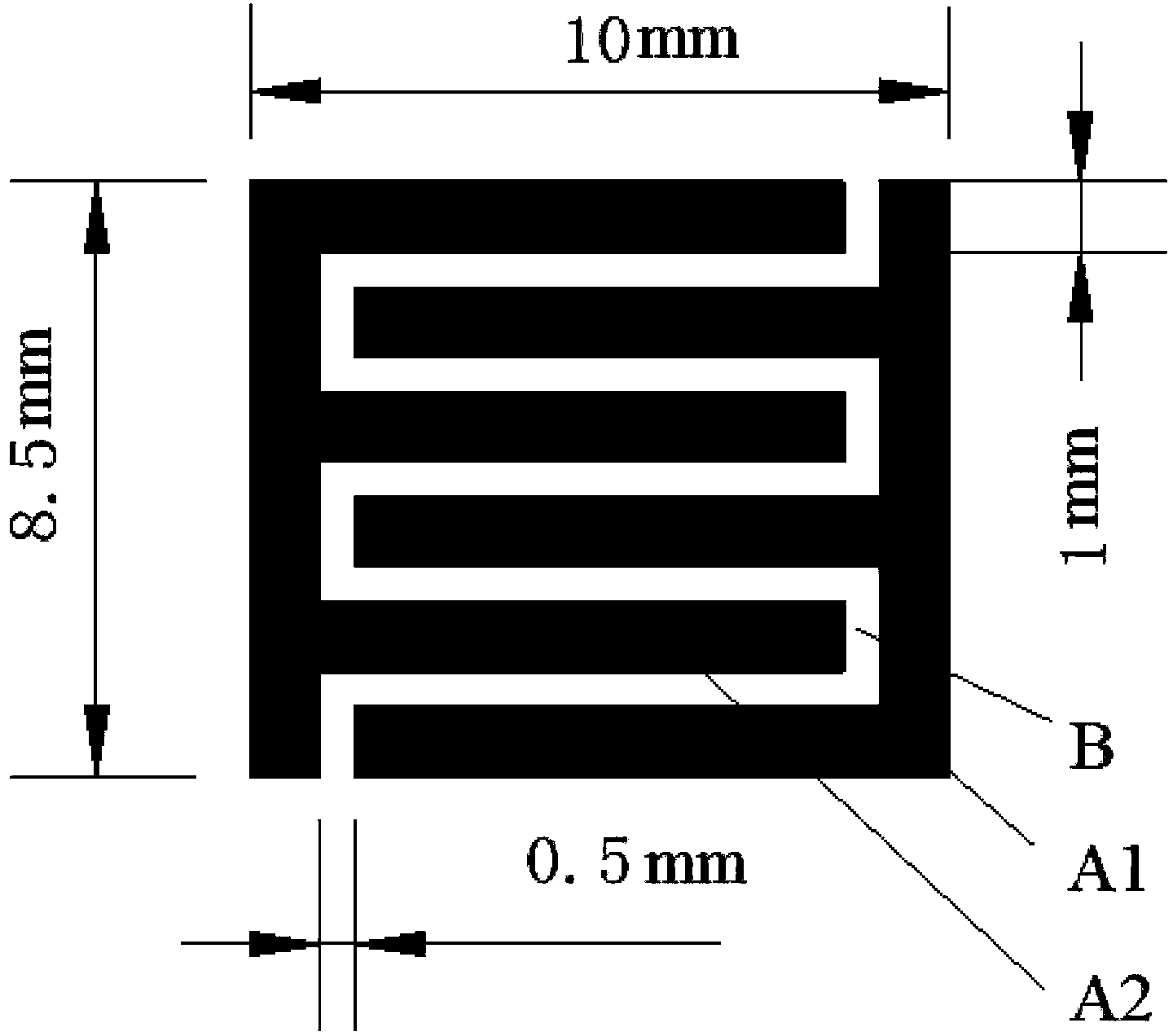

[0083] Thereafter, according to the following steps, a graphene electrode with an interdigitated shape is formed through laser reduction.

[0084] 1. Install Nero software on the working machine.

[0085] 2. Use Nero Cover Designer software to design the appearance shape of the graphene electrode as an interdigitated shape (such as figure 2 The shown A1 and A2 respectively represent the positive and negative graphene electrodes), and set the irradiation parameters such as grayscale and printing contrast.

[0086] 3. Paste the substrate with the pre-r...

Embodiment 2

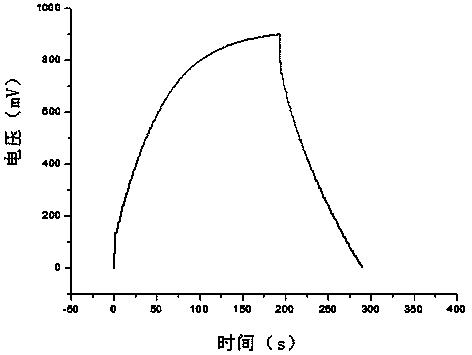

[0095] Below, refer to Figure 2 ~ Figure 4 A graphene supercapacitor 100 according to Embodiment 2 of the present invention is described.

[0096] Such as image 3 As shown, the graphene supercapacitor 100 includes: a housing (not shown); graphene electrode LSG (that is, the graphene electrode obtained in Example 1); collector electrodes M1, M2; package E, and electrolyte solution (not shown in the figure) Show).

[0097] Wherein, the substrate of the graphene electrode is a PET film (P shown in the figure); the collectors M1 and M2 are copper tapes, which are the collectors of the graphene electrode LSG; the graphene electrode LSG is the graphene electrode obtained in Example 1 , which is formed into an interdigitated shape, and the graphite oxide B between the positive and negative graphene electrodes A1 and A2 of the interdigitated shape naturally isolates the electrodes in space (such as figure 2 shown), thereby omitting the diaphragm part of the conventional supercap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com