Preparation method and application of carbon-coated graphene composite material for lithium ion battery

A composite material, graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of fast capacity decay, low irreversible capacity loss, and graphene specific surface, etc. Easy-to-control, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

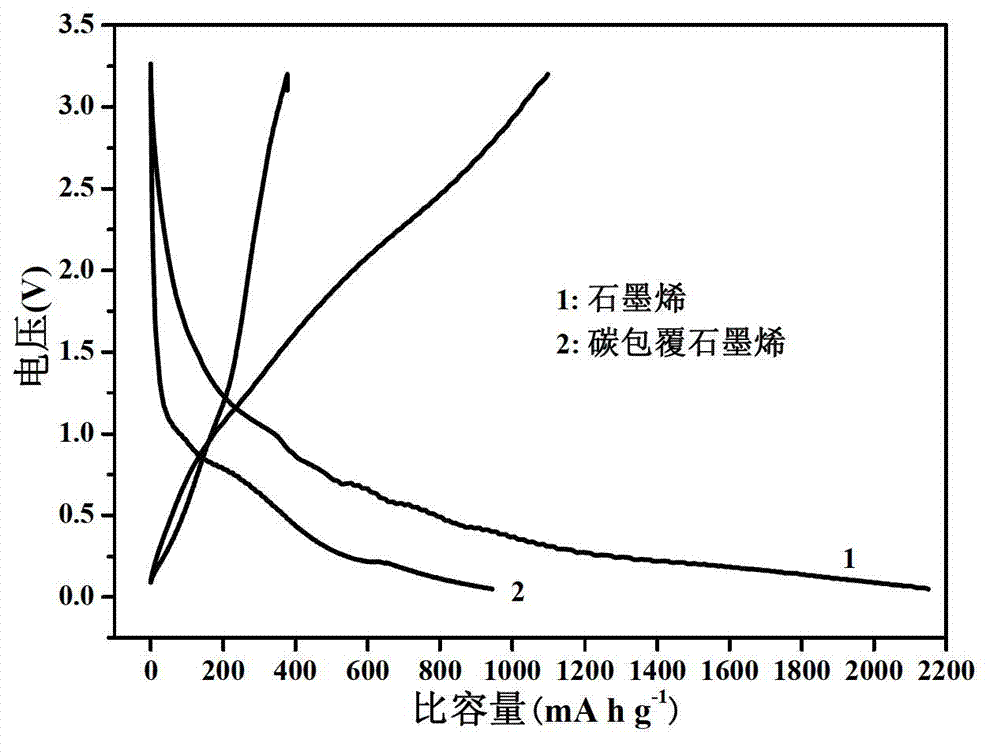

Examples

Embodiment 1

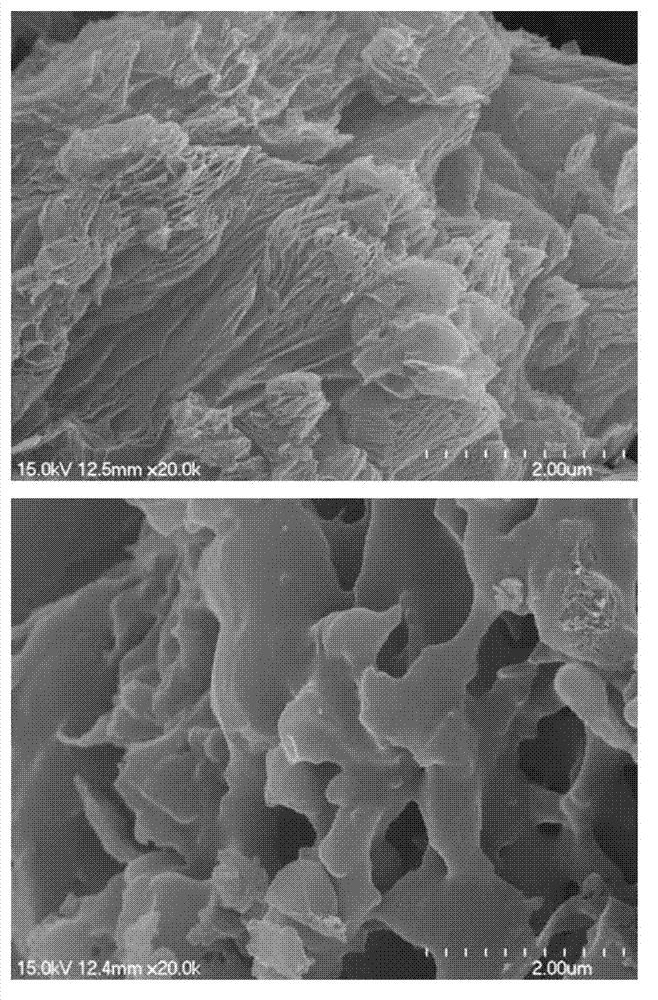

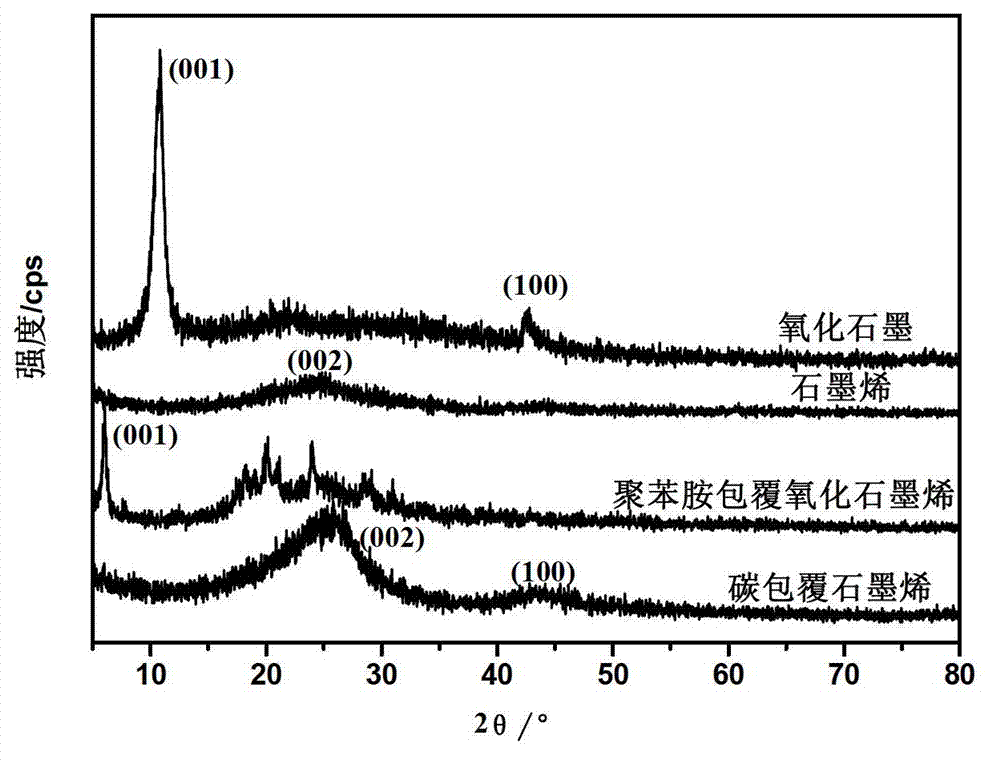

[0030] (1) The preparation method of raw material graphene oxide: the improved Hummers method is used to prepare graphite oxide, specifically: slowly add 1g of graphite into a round bottom flask containing 35ml of 98% sulfuric acid under stirring, and then add 0.5g of sodium nitrate , the temperature was maintained at 0° C., and stirred rapidly for 2 hours. Slowly add 5g of potassium permanganate (temperature controlled below 20°C), it turns dark green, remove the ice water bath after adding potassium permanganate, control the temperature at (35±3)°C, keep stirring for 2 hours, slowly add 100ml of distilled water (The temperature rose to 98°C), stirred rapidly at this temperature for 2.5h, and then stirred slowly for 15h. The product was first treated with 30% H 2 O 2 Wash with aqueous solution, then wash with 5% hydrochloric acid solution, and wash with deionized water until there is no SO in the filtrate 4 2- (BaCl 2 No white precipitate was detected)...

Embodiment 2

[0034] The preparation method of this embodiment is the same as that of Example 1, wherein the mass of graphite oxide and the volume ratio of aniline monomer in step (2) are adjusted to 1:2, and the concentration of ammonium persulfate increases according to a certain amount along with the increase of the amount of aniline monomer. The corresponding increase of the ratio, under other conditions unchanged, also obtains a black product, that is, obtains carbon-coated graphene.

Embodiment 3

[0036] (1) The preparation method of the raw material graphene oxide: the same as in Example 1 (1).

[0037] (2) The preparation method of polypyrrole-coated graphene oxide: disperse 0.5g graphite oxide in 1M hydrochloric acid solution, ultrasonically disperse for 30min to form a stable graphene oxide solution; add 0.5ml pyrrole monomer into the solution, and continue Stir, then slowly drop 11.5g / L ammonium persulfate solution into the above solution, and keep the polymerization reaction at 0-4°C for 4-6h. The obtained polypyrrole-coated graphite oxide was repeatedly washed alternately with ethanol and deionized water for 3-4 times, and vacuum-dried at 60° C. for more than 12 hours to obtain a product, that is, polypyrrole-coated graphene oxide.

[0038] (3) Carbonization of polypyrrole-coated graphene oxide: Grind the polypyrrole-coated graphene oxide obtained in (2), put it into a porcelain boat, place it in the middle heating area of a tube furnace, and feed it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com