Grapheme electrode and preparation method and application thereof

A graphene electrode and electrode technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of limiting the practical application of AC line filters, large internal resistance, poor frequency response, etc., and achieve improved fast charging Discharge speed, high specific capacitance, and the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

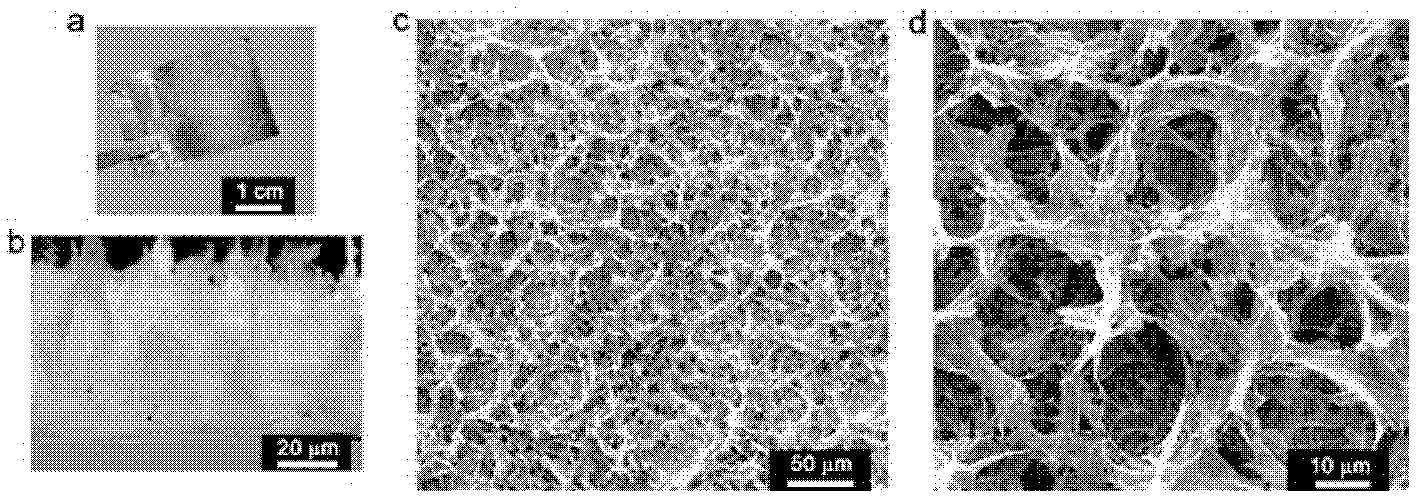

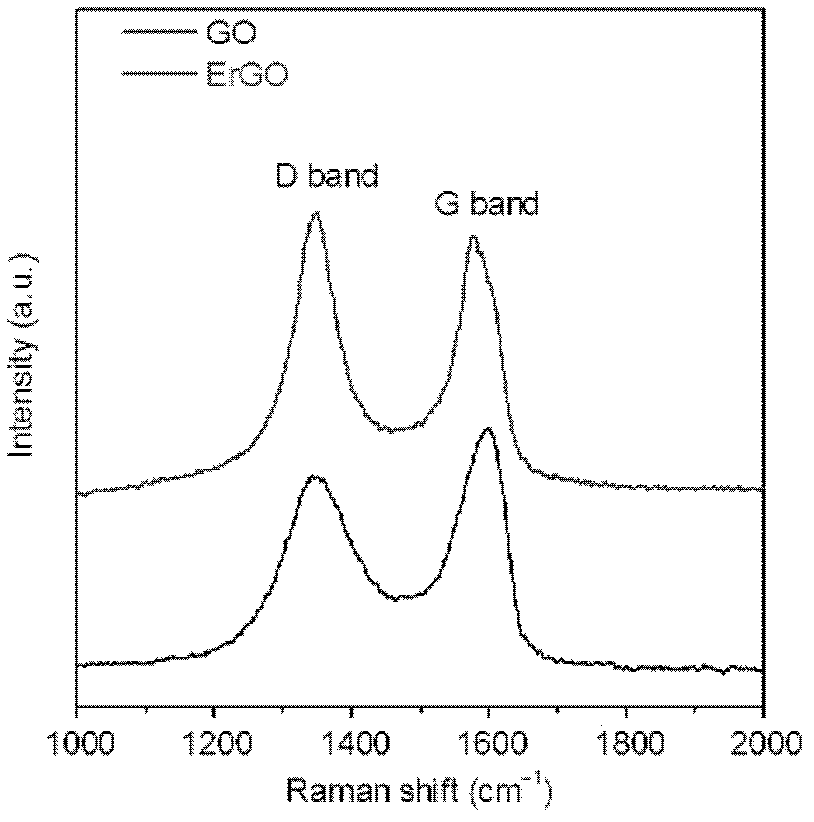

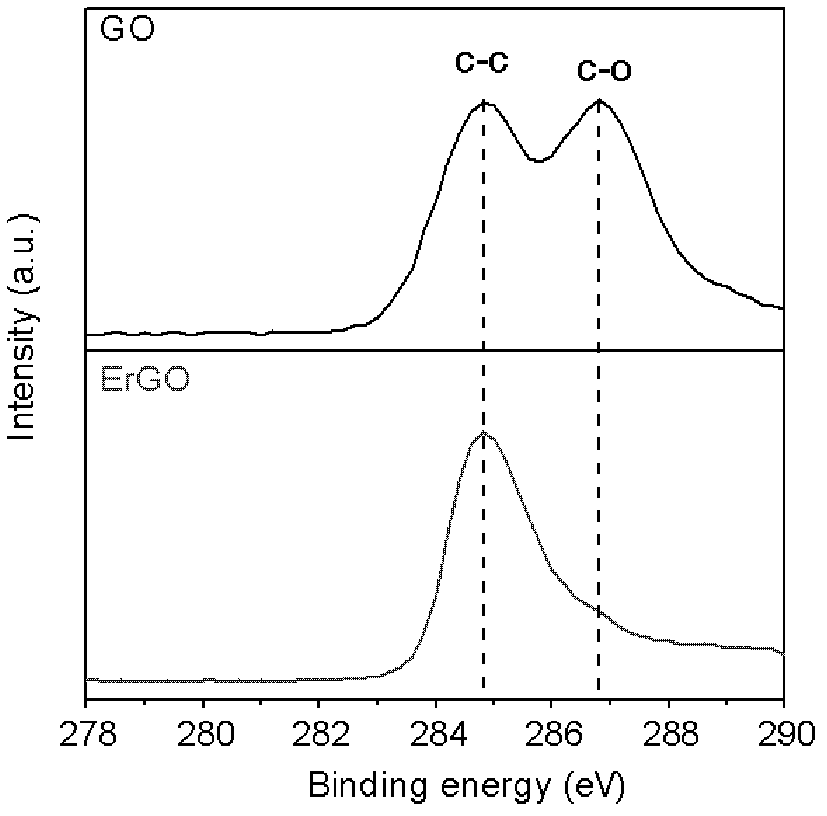

Embodiment 1

[0031] The graphene oxide aqueous solution is ultrasonically dispersed in the lithium perchlorate aqueous solution as the electrolyte, so that the concentration of graphene oxide is 3 mg / mL, and the concentration of lithium perchlorate is 0.1 mol / L. Electrode method (using a polished gold substrate with a thickness of 200 microns as the working electrode, a saturated calomel electrode as the reference electrode, and a platinum sheet as the counter electrode) for electrochemical reduction reaction for 10 seconds, the test electrode area is 1.4cm 2 After the reaction is completed, the product is reduced in a lithium perchlorate aqueous solution with a concentration of 1 mol / L for 30 seconds, and rinsed with deionized water to obtain a graphene electrode with a three-dimensional porous network structure provided by the present invention.

[0032]The graphene electrode of the obtained three-dimensional porous network structure prepared by this embodiment is assembled into a superca...

Embodiment 2

[0040] The graphene oxide aqueous solution is ultrasonically dispersed in the lithium perchlorate aqueous solution as the electrolyte, so that the concentration of graphene oxide is 2.5mg / mL, the concentration of lithium perchlorate is 0.1mol / L, and the polished nickel substrate is used as the working electrode , the saturated calomel electrode is the reference electrode, and the platinum sheet is the counter electrode. Under the potential of -1.2V, the electrochemical reduction reaction is carried out by the three-electrode method for 10 seconds, and the test electrode area is 1.4cm 2 After the reaction is completed, the product is reduced in 1mol / L lithium perchlorate aqueous solution for 30 seconds, and then rinsed with deionized water to obtain a graphene electrode with a three-dimensional porous network structure.

[0041] The graphene electrode of the obtained three-dimensional porous network structure prepared in this embodiment is assembled into a supercapacitor of symm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com