Method for directly preparing co-doping three-dimensional graphene electrode material through biomass carbon sources

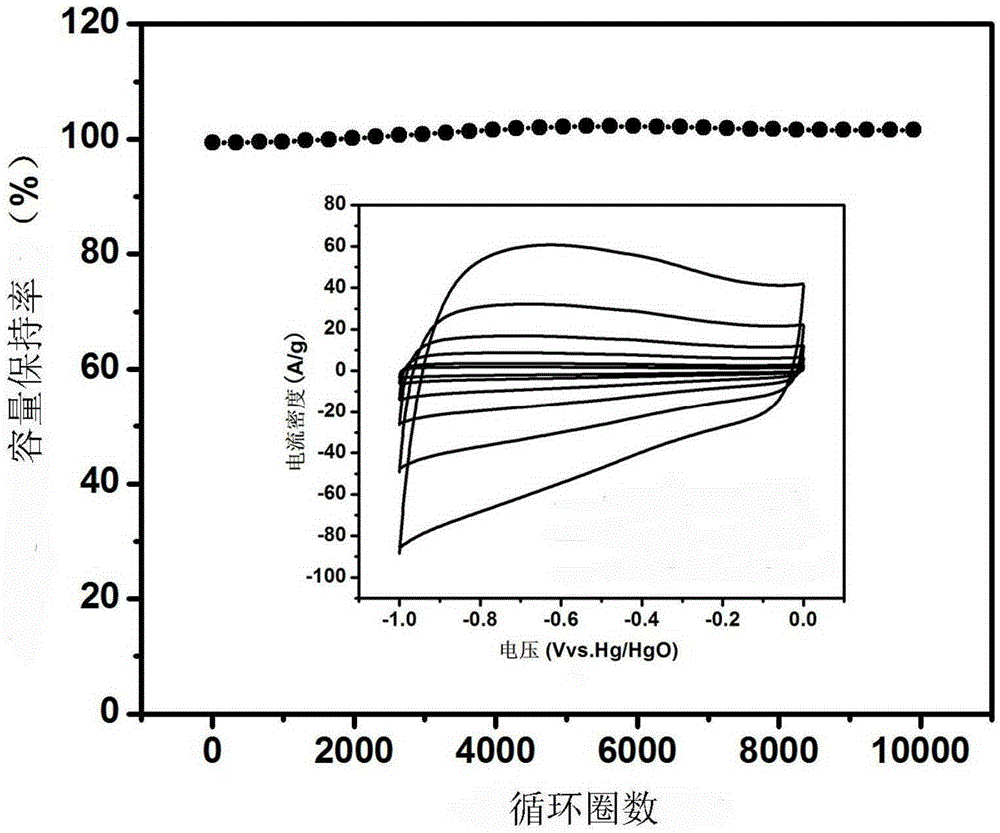

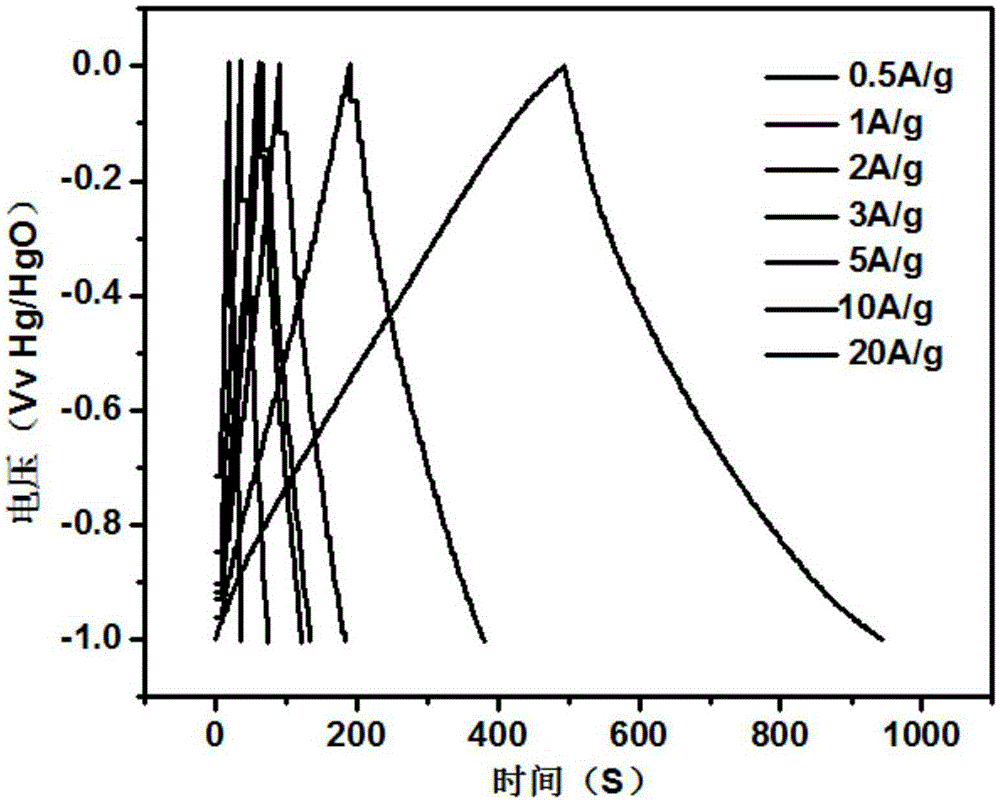

A technology of graphene electrode and biomass carbon source, which is applied in the field of electrode materials, can solve the problems that graphene preparation is difficult to control, cannot be mass-produced, and limits the application of graphene, so as to achieve good cycle stability, stable product quality, and improved The effect of practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

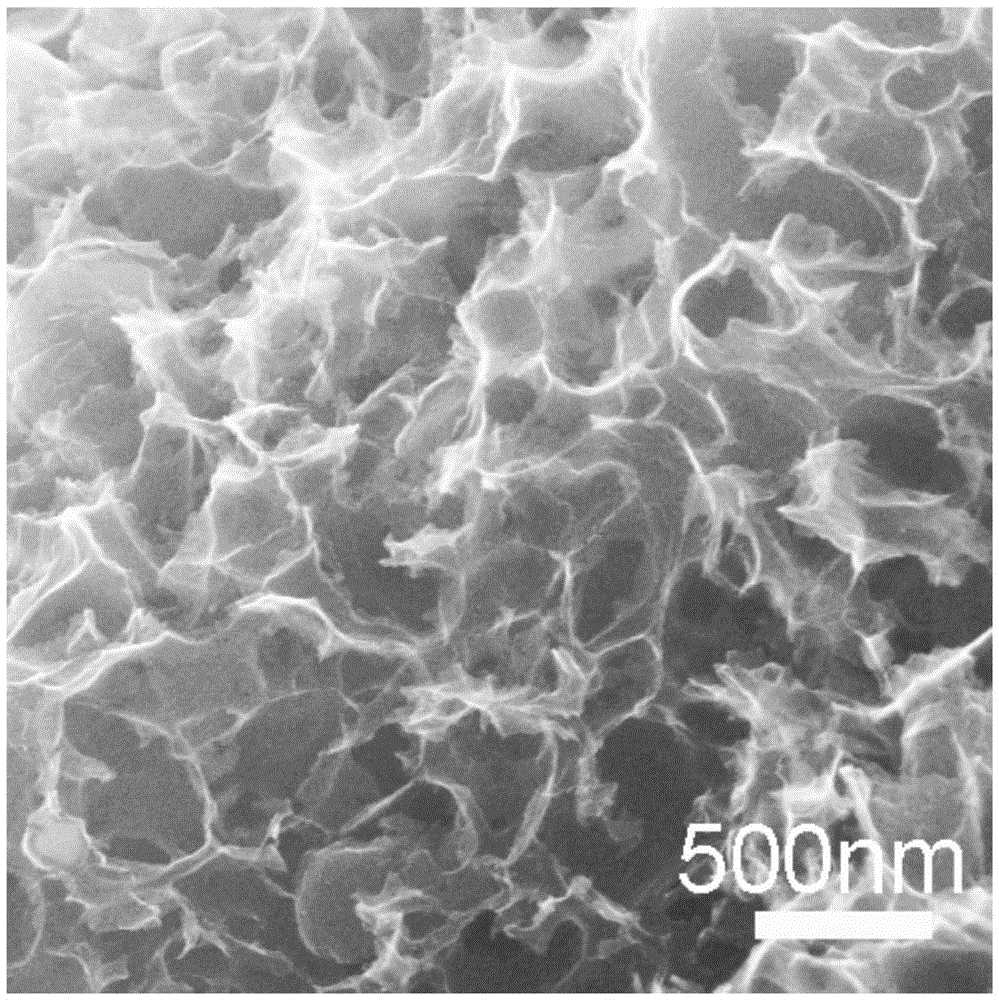

Embodiment 1

[0027] Clean the Artemia egg shells, dry them at 120°C, ball mill them for 3 hours, wash them with hydrochloric acid in turn, wash them with deionized water until pH = 7, and finally dry them; take 0.25g of the above-mentioned treated Artemia egg shells and add Add 100ml of nickel acetate solution with a concentration of 0.01mol / L, stir for 0.5h, add 10ml of potassium hydroxide solution with a concentration of 0.89mol / L, then add 0.083g of red phosphorus, then heat the above solution to 80°C and stir at a high speed Evaporate to a paste. Put the obtained pasty substance into an oven for drying at 80°C, then grind it into fine powder and put it into a tube furnace, control the heating rate at 2°C / min, calcinate at 700°C and keep it warm for 2 hours; pickle the obtained product, wash it with water, Adjust pH=7, filter and dry to obtain doped hierarchical pore structure graphene with high degree of graphitization.

[0028] Grind the obtained graphene into powder, respectively ta...

Embodiment 2

[0031] Clean the Artemia egg shells, dry them at 120°C, ball mill for 5 hours, wash them with hydrochloric acid in turn, wash them with deionized water until pH = 7, and finally dry them; take 2.76g of the above-mentioned treated Artemia egg shells and add Add 100ml of nickel acetate solution with a concentration of 0.05mol / L, stir for 1.5h, add 40ml of potassium hydroxide solution with a concentration of 3mol / L, and then add 1.92g of red phosphorus, then heat the above solution to 120°C, and evaporate it to mushy. Put the obtained pasty substance into an oven for drying at 80°C, then grind it into a fine powder and put it into a tube furnace, control the heating rate at 2°C / min, calcinate at 800°C and keep it warm for 3 hours; pickle the obtained product, wash it with water, Adjust pH=7, filter and dry to obtain doped hierarchical pore structure graphene with higher degree of graphitization.

[0032] Grind the obtained graphene into powder, respectively take 85 mg of graphen...

Embodiment 3

[0035] Clean the Artemia egg shells, dry them at 120°C, ball mill them for 6 hours, wash them with hydrochloric acid, wash them with deionized water until pH=7, and finally dry them; take 5.32g of the above-mentioned treated Artemia egg shells Add it to 80ml of nickel acetate solution with a concentration of 0.05mol / L, stir for 2 hours, add 60ml of potassium hydroxide solution with a concentration of 4mol / L, and then add 11.26g of red phosphorus, then heat the above solution to 150°C, and quickly stir and evaporate until mushy. Put the obtained pasty substance into an oven for drying at 80°C, then grind it into a fine powder and put it into a tube furnace, control the heating rate at 2°C / min, calcinate at 800°C and keep it warm for 4 hours, pickle the product, wash it with water, and adjust the pH = 7, filtered and dried to obtain graphene with a higher degree of graphitization doped hierarchical pore structure.

[0036] Grind the obtained graphene into powder, respectively t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com