Organic semiconductor photoelectric device based on graphene electrode

A technology of organic semiconductors and graphene electrodes, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve problems such as large-area low-cost manufacturing, indium atomic diffusion, and incompatible production technologies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of graphene composite anode A

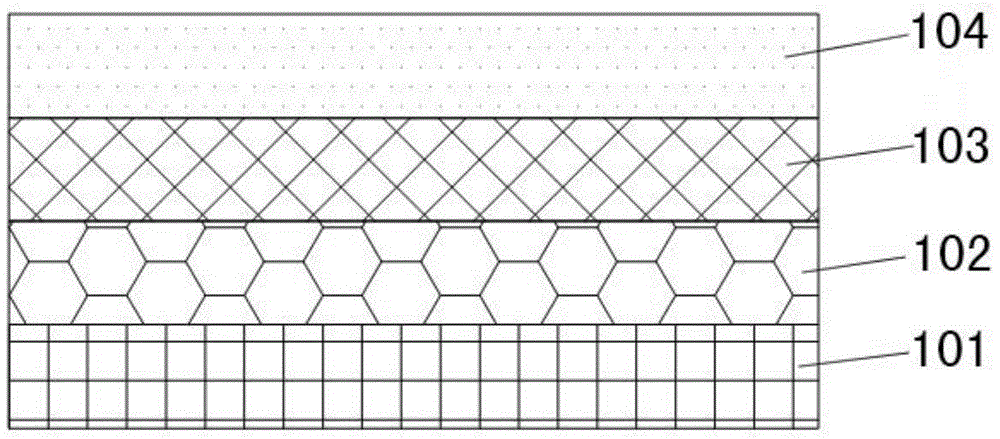

[0045] The float polished glass was cleaned with deionized water, acetone, and IPA for 20 minutes, and then dried with nitrogen gas as the substrate. Single-layer graphene was prepared by chemical vapor deposition, and a two-layer graphene film was obtained by multiple transfers. 3 Doped and transferred to a glass substrate. The silver grid was prepared by photolithography, the line spacing of the grid was set to 200 μm, and the line width was 5 μm, and then transferred to the graphene film. Then spin-coat a layer of PEDOT:PSS conductive polymer layer on the metal grid, heat treatment at 130°C for 10 minutes. The resulting graphene anode is as figure 1 As shown, the square resistance is 7Ω / □, the light transmittance is 86%, and the work function is 5.2eV.

Embodiment 2

[0046] Embodiment 2: Preparation of graphene composite anode B

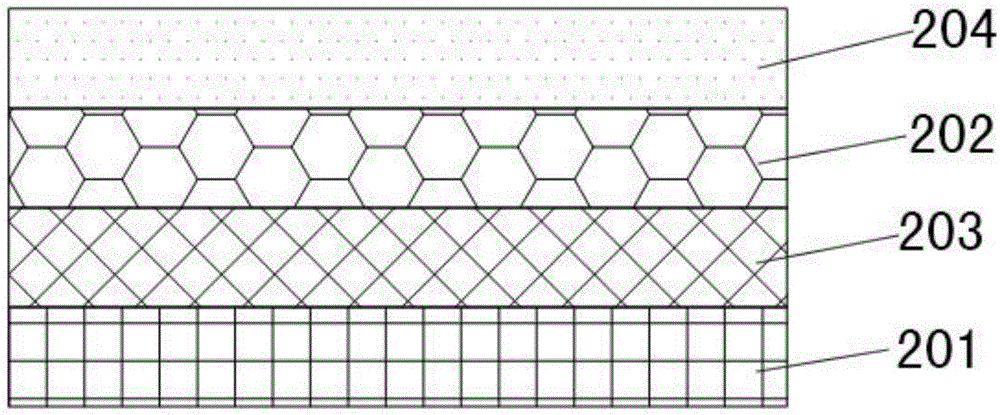

[0047] The PET was washed with deionized water, acetone, and IPA for 20 minutes, and then dried with nitrogen to serve as a substrate. A layer of silver film was sputtered on the PET, and the silver film on the PET was etched into a grid with a line spacing of 100 μm and a line width of 5 μm by photolithography. Single-layer graphene was prepared by chemical vapor deposition, and a three-layer graphene film was obtained by multiple transfers. 3 After doping, transfer to the metal grid. Then spin-coat a layer of PEDOT:PSS conductive polymer layer on the graphene film, heat treatment at 130°C for 10 minutes. The resulting graphene anode is as figure 2 As shown, the square resistance is 1.2Ω / □, the light transmittance is 80%, and the work function is 5.2eV.

[0048] Embodiment 3: preparation doping modified graphene cathode

[0049] The glass substrate was cleaned with ionized water, acetone, and IPA for 20 mi...

Embodiment 4

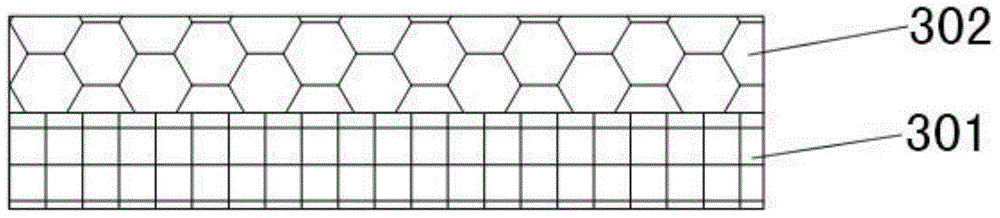

[0050] Embodiment 4: prepare the graphene negative electrode that is adsorbed with surface modification layer

[0051] The PET substrate was cleaned with ionized water, acetone, and IPA for 20 minutes, and then dried with nitrogen. Single-layer graphene was prepared by chemical vapor deposition, and two-layer graphene films were obtained by multiple transfers. Branched polyethyleneimine (PEI) was doped in ethylene glycol monomethyl ether solvent at a mass ratio of 0.4%. The prepared solution was spin-coated on the graphene film at a speed of 5000 rpm, and then heat-treated on a hot plate at 100° C. for 10 minutes to obtain a graphene cathode adsorbed with 10 nmPEI. The resulting graphene cathode is as Figure 4 As shown, its work function is 3.7eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com