Preparation method of stable graphene colloid

A technology of graphene and colloid, applied in the field of preparation of graphene stable colloid, which can solve the problems of easy precipitation, easy agglomeration of graphene, unfavorable graphene application, etc., and achieve the effect of simple preparation method and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

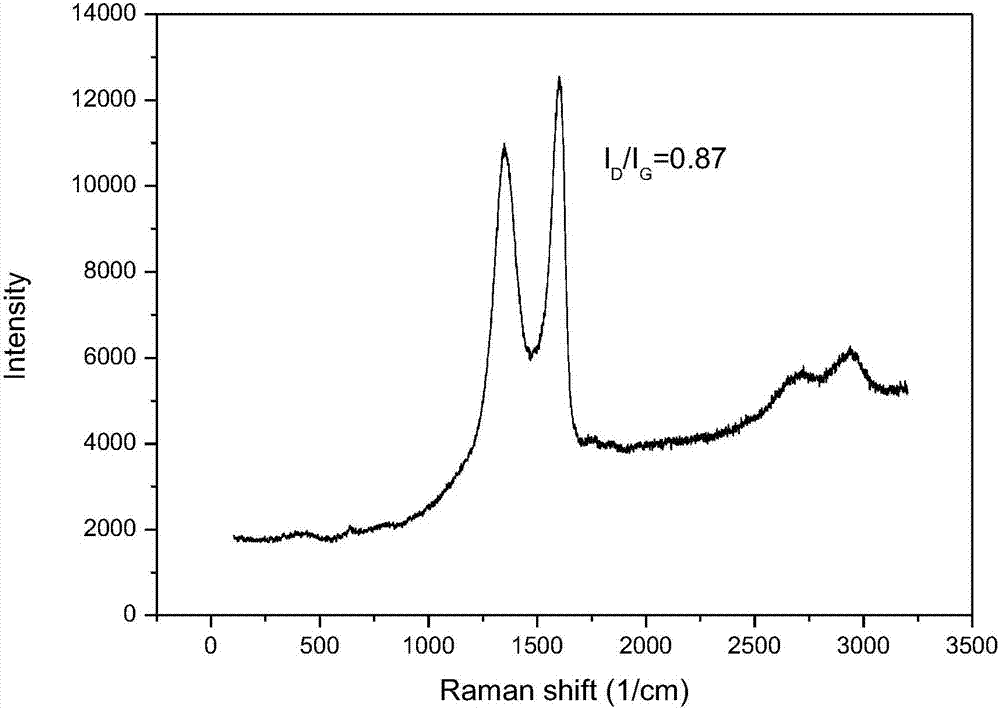

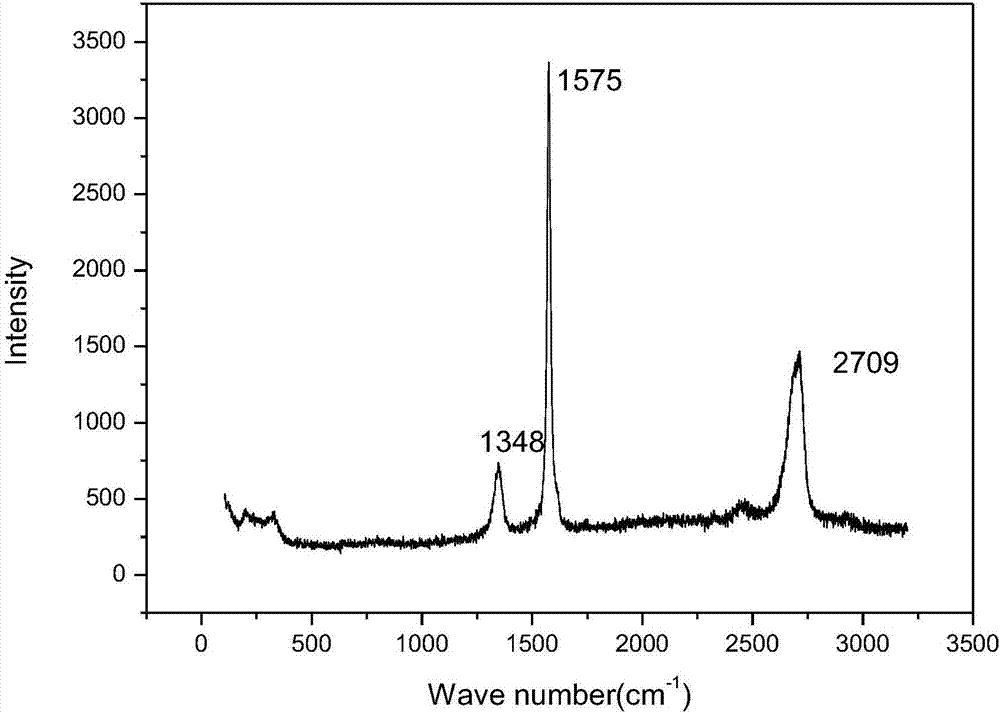

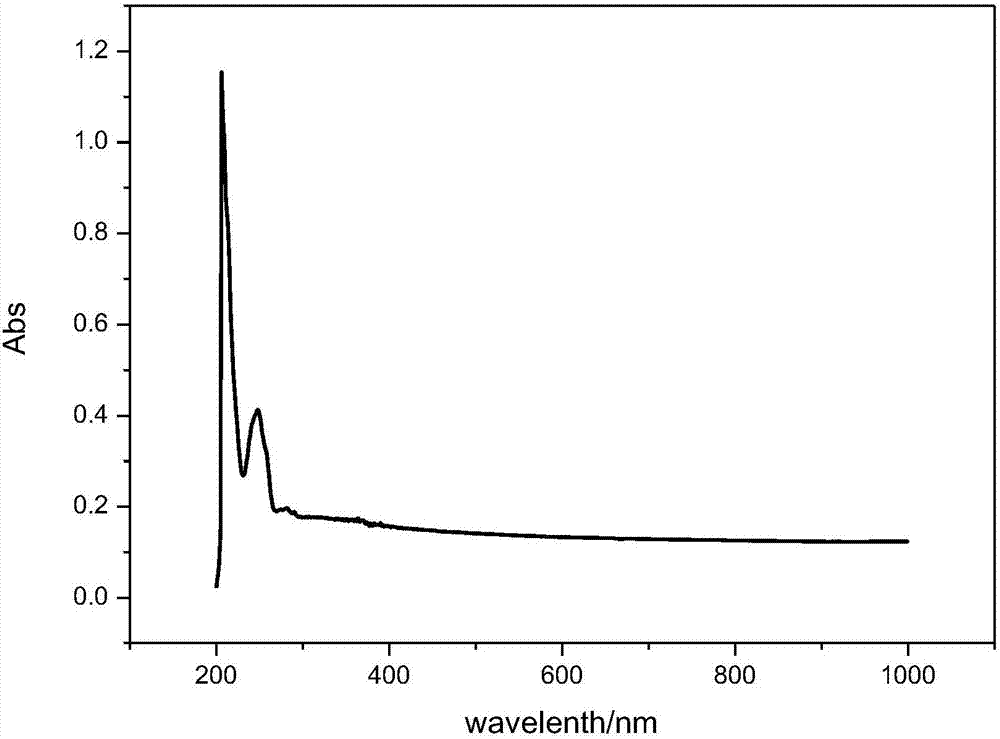

Image

Examples

Embodiment 1

[0027] Ultrasonicate 5g of graphite powder, 0.3g of carbon quantum dots, 15g of 3-[3-(cholamidopropyl)dimethylamino]propanesulfonic acid inner salt, 10g of polytetrafluoroethylene, and 15g of polystyrene emulsion in 500mL of ethanol Disperse for 30 minutes, and then shear at high speed for 3 hours to obtain a stable graphene colloid.

Embodiment 2

[0029] 1g of graphite powder, 3g of graphene oxide nanoparticles, 25g of n-hexadecyl-β-D-maltoside, and 10g of polyethylene glycol were ultrasonically dispersed in 150mL DMF for 30 minutes, then 3g of polyacrylic acid emulsion was added, and high-speed shearing After cutting for 3 hours, a stable graphene colloid is obtained.

Embodiment 3

[0031] 10g of graphite powder, 45g of graphene oxide nanoparticles, 500g of n-hexadecyl-β-D-maltoside, and 150g of polyethylene glycol were ultrasonically dispersed in 750mL of water for 2 hours, then 30g of polyacrylic acid emulsion was added, and high-speed shearing After cutting for 3 hours, a stable graphene colloid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com