Preparation method and apparatus for rare earth element dopped gallium nitride powder material

A rare earth element and powder material technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor luminescence uniformity, large lattice, distortion, etc., to improve the poor luminescence uniformity, improve luminescence performance, improve The effect of lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

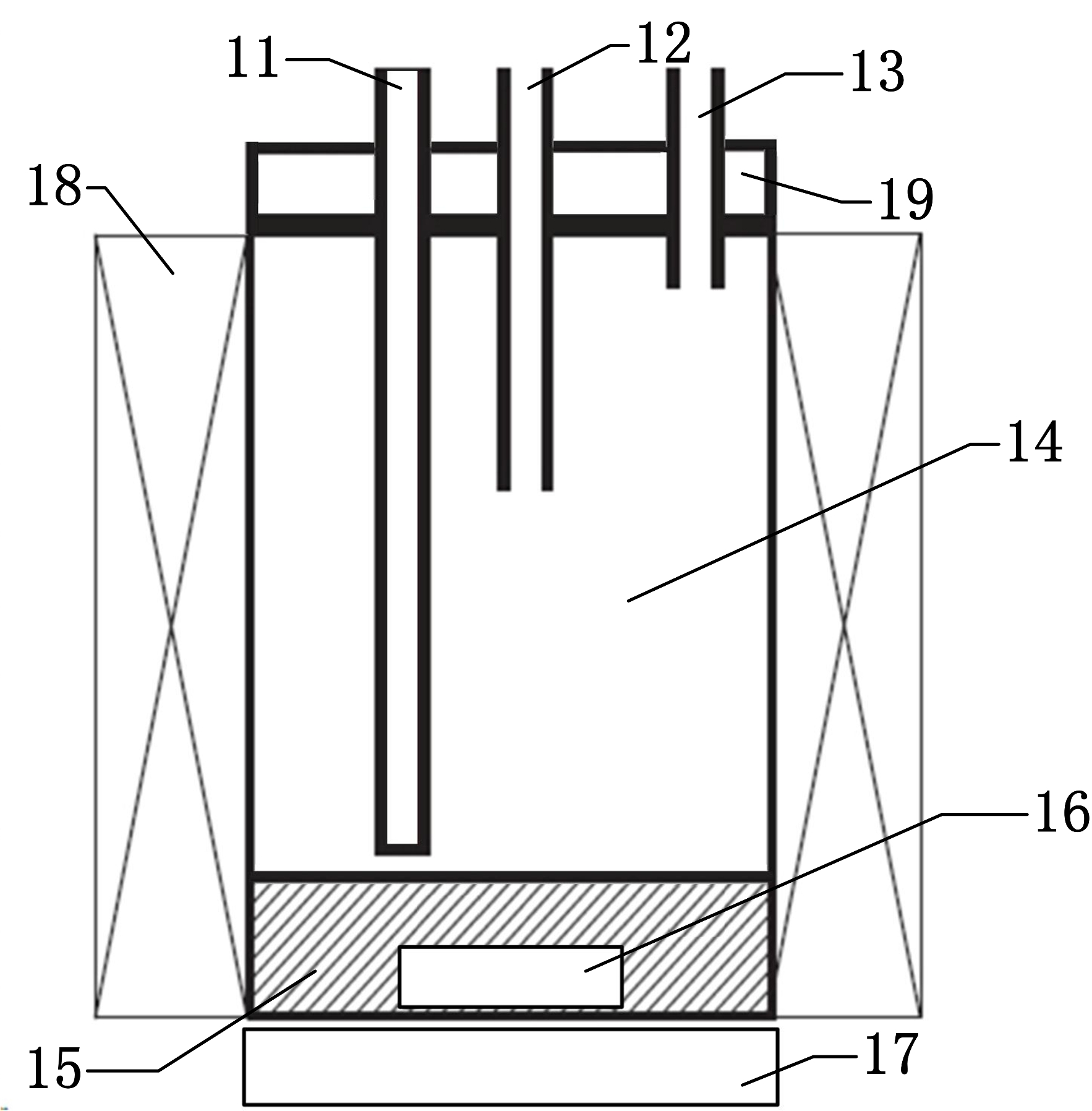

[0028] figure 1 Shown is a schematic structural view of the first specific embodiment of the device for preparing rare earth element-doped gallium nitride powder materials provided by the present invention.

[0029] This specific embodiment provides a device for preparing gallium nitride powder materials doped with rare earth elements, including a furnace body 18 and a reaction chamber 14, the reaction chamber 14 is located inside the furnace body 18, and the furnace body 18 is used To adjust the temperature of the reaction chamber 14. The reaction chamber 14 includes a flange 19 with a hole. The flange 19 is located at the top of the reaction chamber 14 for sealing the device to prevent the gas in the reaction chamber 14 from leaking. The gas path of the reaction chamber 14 includes an air inlet 12 and an air outlet 13, the air inlet 12 and the air outlet 13 are respectively connected to the outside of the reaction chamber 14 through different holes in the flange 19, ...

no. 2 Embodiment approach

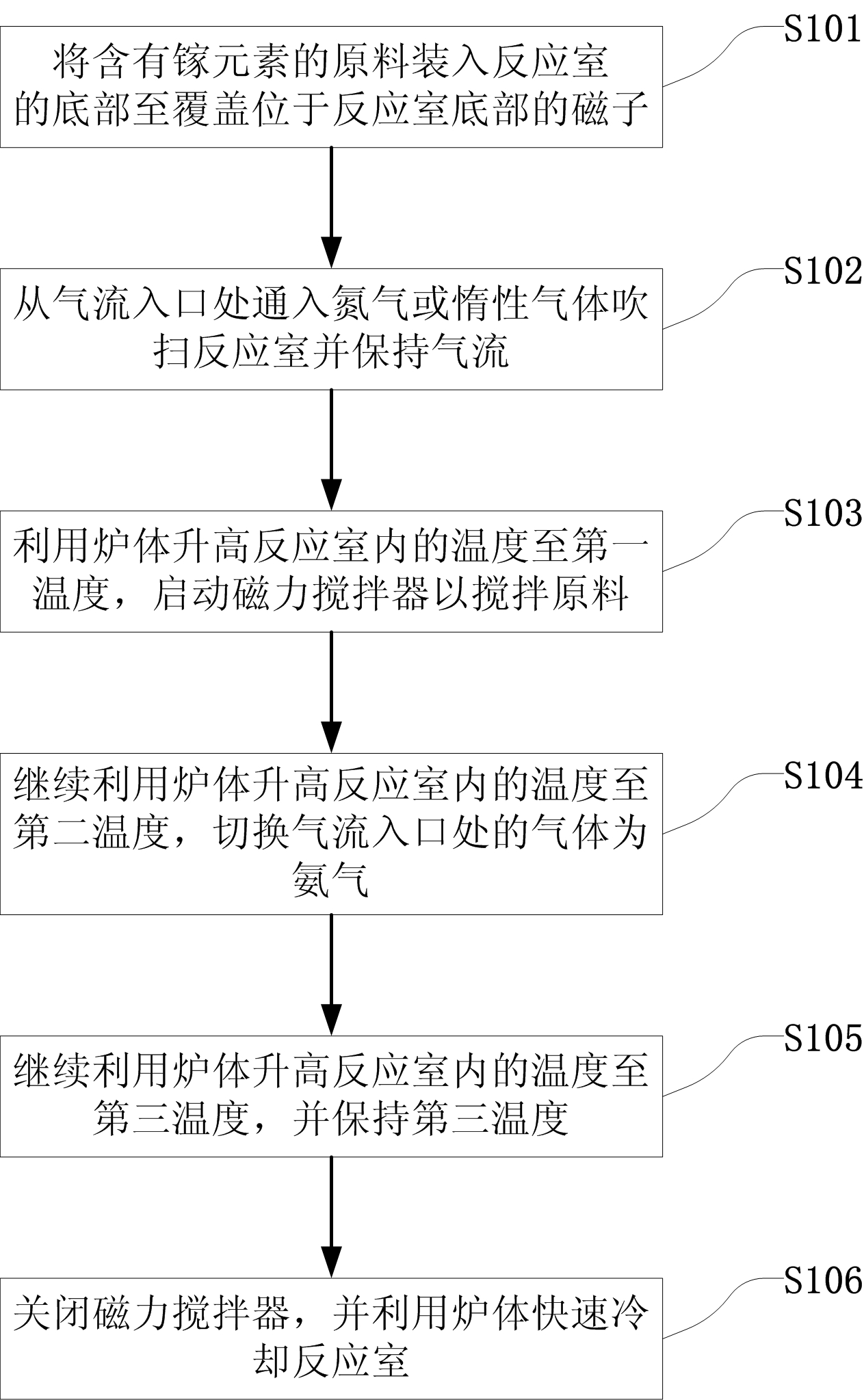

[0036] figure 2 Shown is a flow chart of the steps of the second embodiment of the method for preparing rare earth element-doped gallium nitride powder material provided by the present invention.

[0037] A method for preparing gallium nitride powder material doped with rare earth elements, comprising the steps of:

[0038] S101, loading the raw material containing gallium into the bottom of the reaction chamber to cover the magneton located at the bottom of the reaction chamber;

[0039]S102, passing nitrogen or an inert gas from the gas flow inlet to purge the reaction chamber and maintaining the gas flow;

[0040] S103, using the furnace body to increase the temperature in the reaction chamber to the first temperature, and start the magnetic stirrer to stir the raw materials;

[0041] S104, continue to use the furnace body to increase the temperature in the reaction chamber to the second temperature, and switch the gas at the gas flow inlet to ammonia gas;

[004...

Embodiment 1

[0059] In this embodiment, x=0.1%, y=0.01%, the rare earth element is Er, and the group III element is boron B. The above-mentioned weighed raw materials are mixed and loaded into the bottom of the reactor of the device to cover the magnet, and the magnetic stirrer is turned off at this time. Pass high-purity nitrogen (flow rate: 400 sccm) to purge the reactor for one hour, then raise the temperature, keep the nitrogen flow, and turn on the magnetic stirrer when the system temperature is higher than 300°C. When the temperature continues to rise to 600°C, the gas is switched to ammonia (flow rate is 200 sccm). When the temperature of the system is raised to 1000°C, it is nitrogenized at a constant temperature, and the holding time is 4 hours. After the reaction is completed, close the magnetic stirrer, and take out the Er after rapid cooling. 3+ and B 3+ Co-doped GaN powder. B 3+ Doped with the same concentration of Er 3+ GaN powder, the fluorescence intensity is enhanced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com