Rare-earth doped GaN luminescent powder and preparation method thereof

A technology of luminescent powder and rare earth doping, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the luminescence performance of GaN powder, large lattice distortion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In terms of molar ratio, the raw material formula of this embodiment is Ga: Re: A=(1-x-y): x: y, wherein, x=0.1%, y=0.01%, Re is the rare earth metal Er, and A is metal B. The above-mentioned weighed raw materials were vacuum-packed in a quartz tube, and the quartz tube was kept at 500° C. for 8 hours, and then cooled to room temperature. Take out the solid solution in the quartz tube, grind it into a powder, put it into a corundum boat in an ammonia atmosphere, control the temperature at 1000°C, keep it warm for 10h, and then cool it to room temperature to take out the rare earth Er 3+ and B 3+ Co-doped GaN powder material. with no co-doped B 3+ Doped with the same concentration of Er 3+ Compared with GaN powder materials, the fluorescence intensity is enhanced by 5% to 20%. The powder material can be applied to the field of flat panel display.

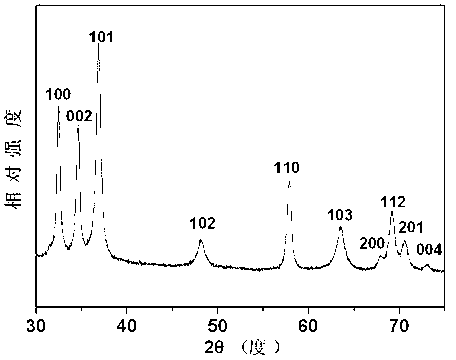

[0018] See attached figure 1 , which is the XRD pattern of the rare-earth-doped GaN luminescent powder provided in thi...

Embodiment 2

[0020] According to the molar ratio of Ga: Re: A=(1-x-y): x: y, in the present embodiment, x=10%, y=1%, Re is the rare earth metal Ce, and A is the metal B. The measured raw materials are vacuum-packed in a quartz tube, and the quartz tube is kept at 1000 ° C for 16 hours, and then cooled to room temperature. Take out the solid solution in the quartz tube, grind it into a powder, put it into a corundum boat in an ammonia atmosphere, control the temperature at 1150°C, keep it warm for 20h, and then cool it to room temperature, then the rare earth Ce can be taken out. 3+ and B 3+ Co-doped GaN powder material. B 3+ Doped with the same concentration of Ce 3+ GaN powder material, the fluorescence intensity is enhanced by 5% to 20%.

Embodiment 3

[0022] According to the molar ratio of Ga:Re:A=(1-x-y):x:y, in this embodiment, x=5%, y=0.5%, Re is the rare earth metal Pr, and A is metal B. The above-mentioned weighed raw materials were vacuum-packed in a quartz tube, and the quartz tube was kept at 800 ° C for 12 hours, and then cooled to room temperature. Take out the solid solution in the quartz tube, grind it into a powder, put it into a corundum boat in an ammonia atmosphere, control the temperature at 1050°C, keep it warm for 15 hours, and then cool it to room temperature to take out the rare earth Pr 3+ and B 3+ Co-doped GaN powder material. B 3+ The same concentration of doped Pr 3+ GaN powder material, the fluorescence intensity is enhanced by 5% to 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com