Rare earth element doped fluorescent powder and preparation method thereof

A technology of rare earth elements and phosphors, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of reducing the luminescence performance of polycrystalline powder materials, large lattice distortion, etc., and achieve the effect of improving luminescence performance and improving lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

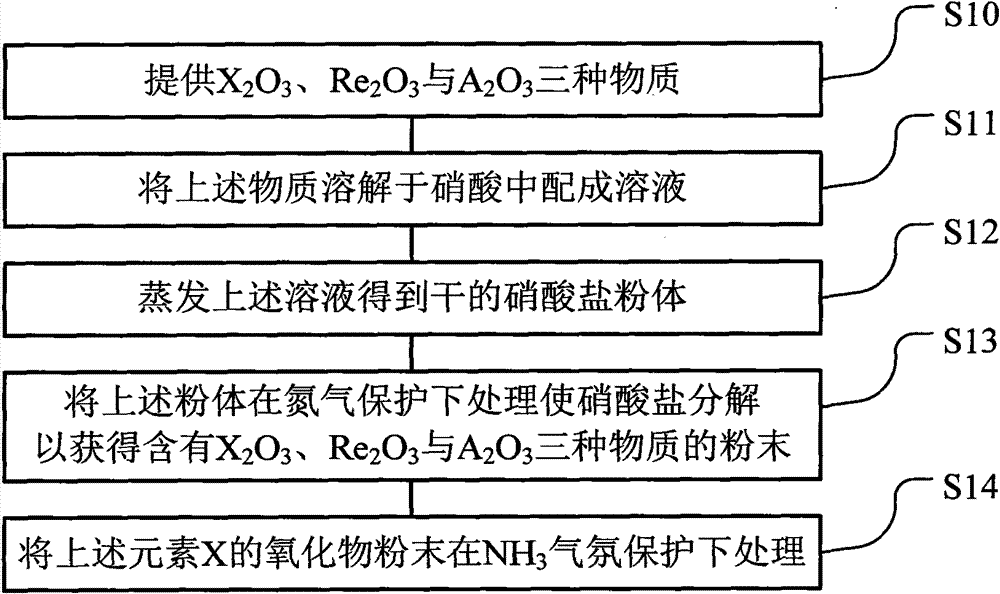

Method used

Image

Examples

Embodiment 1

[0038] In this example, x=0.1%, y=0.01%, Re is Er 3+ , A is boron element B. So put Ga 2 o 3 , Er 2 o 3 , B 2 o 3 The high-purity raw materials are weighed according to the molar ratio of 0.9989:0.001:0.0001, and the above raw materials are dissolved in concentrated nitric acid to make a solution; the above solution is evaporated at a temperature of 80°C to obtain a dry block, and then ground to obtain a powder body. Under the protection of nitrogen, treat at 500°C for 4h to decompose nitrate to obtain Er-doped 3+ and B 3+ Ga 2 o 3 , and further grind the powder. The resulting doped Ga 2 o 3 Powder in NH 3 Under the protection of the atmosphere, the Er-doped 3+ and B 3+ GaN phosphors. B 2 o 3 Doped with the same concentration of Er 3+ GaN phosphor powder, the fluorescence intensity is enhanced by 5%-20%.

Embodiment 2

[0040] In this example, x=10%, y=1%, Re is Er 3+ , A is boron element B. So put Ga 2 o 3 , Er 2 o 3 , B 2 o 3 The high-purity raw materials are weighed according to the molar ratio of 0.89:0.1:0.01, and the above raw materials are dissolved in concentrated nitric acid to make a solution; the above solution is evaporated at a temperature of 100°C to obtain a dry block, and then ground to obtain a powder body. Under the protection of nitrogen, treat at 700°C for 8h to decompose nitrate to obtain Er-doped 3+ and B 3+ Ga 2 o 3 , and further grind the powder. The resulting doped Ga 2 o 3 Powder in NH 3 Under the protection of the atmosphere, the Er-doped 3+ and B 3+ GaN phosphors. B 2 o 3 Doped with the same concentration of Er 3+ GaN phosphor powder, the fluorescence intensity is enhanced by 5%-20%.

Embodiment 3

[0042] In this example, x=5%, y=0.5%, Re is Er 3+ , A is boron element B. So put Ga 2 o 3 , Er 2 o 3 , B 2 o 3 The high-purity raw materials are weighed according to the molar ratio of 0.945:0.05:0.005, and the above raw materials are dissolved in concentrated nitric acid to make a solution; the above solution is evaporated at a temperature of 95°C to obtain a dry block, and then ground to obtain a powder body. Under the protection of nitrogen, treat at 600°C for 6h to decompose nitrate to obtain Er-doped 3+ and B 3+ Ga 2 o 3 , and further grind the powder. The resulting doped Ga 2 o 3 Powder in NH 3 Under the protection of the atmosphere, the Er-doped 3+ and B 3+ GaN phosphors. B 2 o 3 Doped with the same concentration of Er 3+ GaN phosphor powder, the fluorescence intensity is enhanced by 5%-20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com