A low thermal conductivity, high fracture toughness aerospace thermal barrier material and its preparation

An aerospace, low thermal conductivity technology, applied in high fracture toughness aerospace thermal barrier materials and its preparation, low thermal conductivity field, can solve high sintering temperature, material fracture toughness and thermal conductivity are difficult to achieve common improvement, sintering Long time and other problems, to achieve the effect of lowering the sintering temperature, shortening the sintering time, and high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

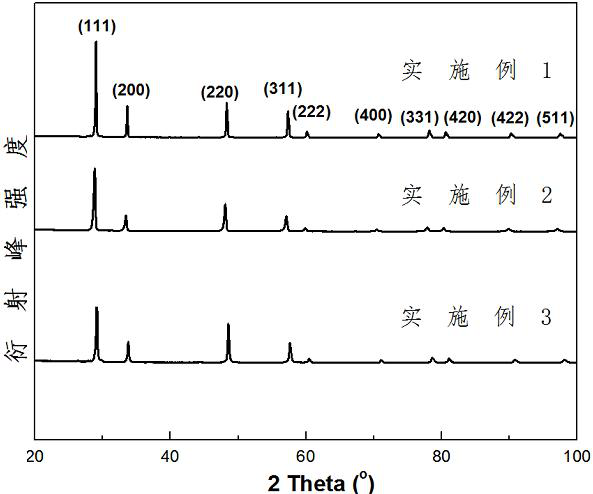

Embodiment 1

[0034] Example 1 Preparation (ZrO 2 ) 1 (CeO 2 ) 1 (HfO 2 ) 1 (Y 2 o 3 ) 0.5 (Sm 2 o 3 ) 0.5 , corresponding to (Zr 1 Ce 1 f 1 Y 1 SM 1 )O 9 High entropy oxides:

[0035](1) Powder mixing: Weigh ZrO according to the atomic ratio of 1:1:1:0.5:0.5 2 , CeO 2 , HfO 2 , Y 2 o 3 、Sm 2 o 3 Powder (particle size 0.5μm, purity ≥ 99.9%), put it into a ball mill jar for ball milling, add 1mL absolute ethanol per 100g of mixed powder as the grinding medium, and the grinding ball is ZrO 2 Balls, the ball-to-material ratio (g / g) is 0.5:1, the ball milling speed is 100r / min, and the ball milling time is 5h. After ball milling, it is dried in a drying oven. After grinding, it is sieved with 100 meshes to obtain a uniformly mixed raw powder. products.

[0036] (2) Sintering: Put the product obtained in step (1) into a graphite mold, and then place it in an SPS discharge plasma sintering furnace for sintering. The sintering temperature is 1550°C, the heating rate is 60°...

Embodiment 2

[0042] Example 2 Preparation (ZrO 2 ) 0.75 (CeO 2 ) 1.25 (HfO 2 ) 1 (Y 2 o 3 ) 0.3 (Sm 2 o 3 ) 0.45, Corresponding (Zr 0.75 Ce 1.25 f 1 Y 0.6 SM 0.9 )O 8.25 High entropy oxides:

[0043] (1) Powder mixing: Weigh ZrO according to the atomic ratio of 0.75:1.25:1:0.3:0.45 2 , CeO 2 , HfO 2 , Y 2 o 3 、Sm 2 o 3 Powder (particle size 30μm, purity ≥ 99.5%), put it into a ball mill jar for ball milling, add 5mL of absolute ethanol per 100g of mixed powder as the grinding medium, and the grinding ball is ZrO 2 Balls, the ball-to-material ratio is 5:1, the ball milling speed is 300r / min, and the ball milling time is 24h. After ball milling, it is dried in a drying oven. After grinding, it is sieved with 200 meshes to obtain a uniformly mixed original powder product.

[0044] (2) Sintering: Put the product obtained in step (1) into a graphite mold, and then place it in an SPS discharge plasma sintering furnace for sintering. The sintering temperature is 1750°C, th...

Embodiment 3

[0050] Example 3 Preparation (ZrO 2 ) 1 (CeO 2 ) 0.75 (HfO 2 ) 1.25 (Y 2 o 3 ) 0.6 (Nd 2 o 3 ) 0.65, Corresponding (Zr 1 Ce 0.75 f 1.25 Y 1.2 Nd 1.3 )O 9.75 High entropy oxides:

[0051] (1) Powder mixing: Weigh ZrO according to the atomic ratio of 1:0.75:1.25:0.6:0.65 2 , CeO 2 , HfO 2 , Y 2 o 3 、Nd 2 o 3 Powder (particle size 10μm, purity ≥ 99.5%), put it into a ball mill jar for ball milling, add 3mL of absolute ethanol per 100g of mixed powder as the grinding medium, and the grinding ball is ZrO 2 Balls, the ball-to-material ratio is 3:1, the ball milling speed is 200r / min, and the ball milling time is 12h. After the ball milling, it is dried in a drying oven. After grinding, it is sieved with 150 meshes to obtain a uniformly mixed original powder product.

[0052] (2) Sintering: Put the product obtained in step (1) into a graphite mold, and then place it in an SPS discharge plasma sintering furnace for sintering. The sintering temperature is 1600°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com