System and method for preparing ferrochrome

A technology of ferrochromium alloy and chromite powder, which is applied in the field of metallurgy and can solve the problems of ineffective utilization of poor chromite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

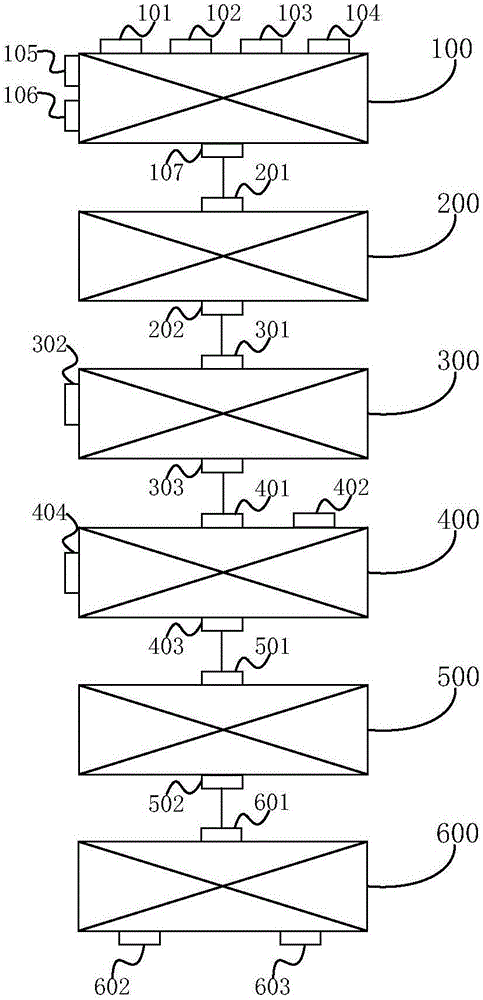

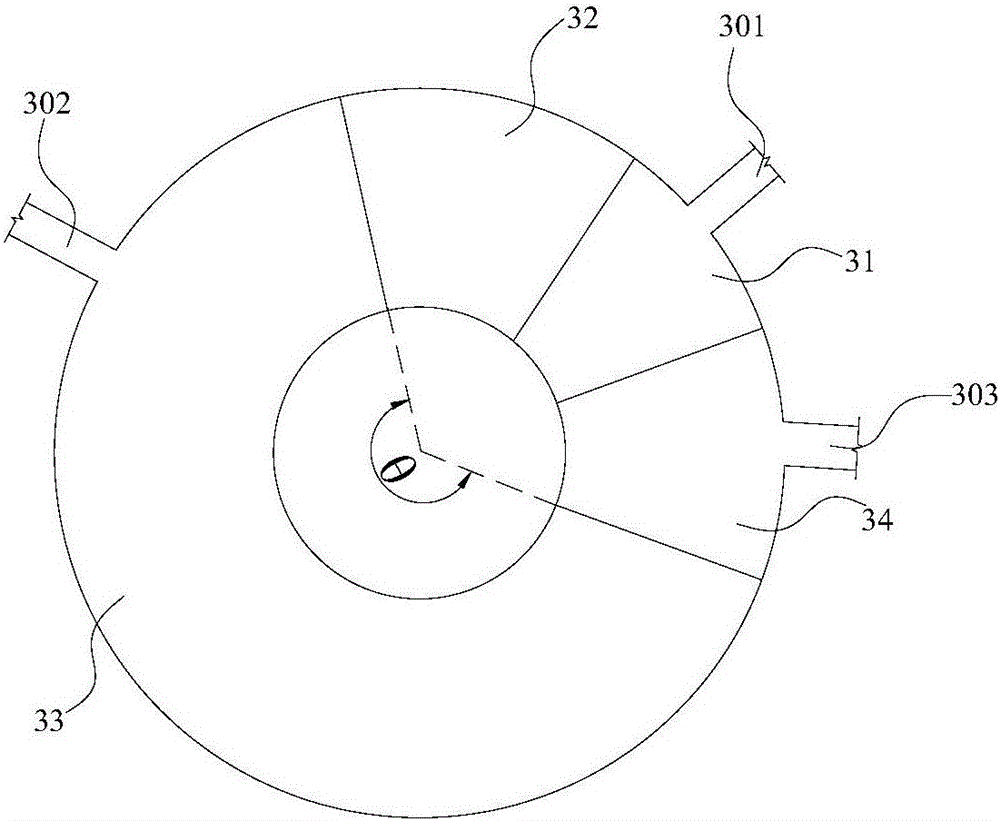

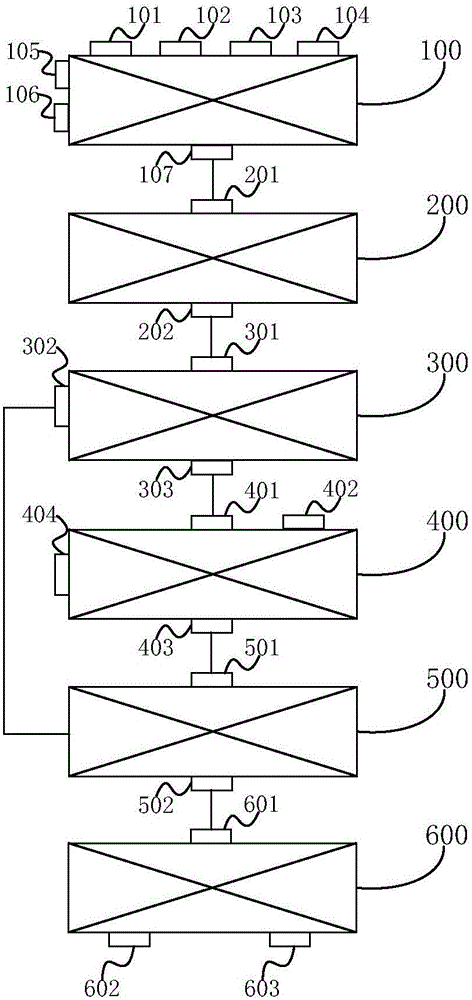

[0061] The system for preparing ferrochrome alloy according to the embodiment of the present invention uses a rotary hearth furnace to reduce and roast the dried pellets containing carbonaceous materials, silica, flux, binder and chromite powder. The temperature and atmosphere of the inner reduction zone are used to achieve the selective reduction of iron oxides and chromium oxides in chromite ore powder, so that most of the iron oxides in chromite ore powder are reduced to metallic iron and iron carbide, while a small part Chromium oxide is reduced to chromium carbide, and then the obtained solid reduction product is subjected to acid leaching treatment, in which metallic iron and iron carbide are dissolved by the acid solution and enter the leaching solution, while dichromium trioxide and chromium carbide are insoluble in the acid solution and enter the leaching solution. The chromium-iron ratio in the leaching residue can be significantly increased (the chromium-iron ratio i...

Embodiment 1

[0095] With chromite as raw material, Cr 2 o 3 Content is 35.47wt%, Cr 2 o 3 / FeO=2.1, the chromite ore is ground to -200 mesh, accounting for 65%, the amount of silica added is 6% of the weight of chromite ore, the amount of carbon added is 1.1 times the stoichiometric requirement, and the amount added accounts for chromite 9% binder (the binder contains bentonite and molasses) of iron ore powder mass, mixed with 3% flux (flux contains limestone and Na 2 CO 3 , and Na 2 CO 3 The weight ratio of limestone to limestone is 1:5), and the materials are mixed and pelletized to obtain mixed wet pellets with a diameter of 10-14mm. After the obtained mixed wet pellets are dried, the dried pellets are distributed into the rotary hearth furnace. The maximum temperature in the furnace is set at 1300°C. After the pellets are reduced in the furnace for 60 minutes, they are discharged from the rotary hearth furnace with a screw discharger. The pellets are piled up and leached with dil...

Embodiment 2

[0097] With chromite as raw material, Cr 2 o 3 The content is 38.15wt%, Cr 2 o 3 / FeO=1.95, the chromite ore is ground to -200 mesh, accounting for 75%, the amount of silica added is 8% of the weight of chromite ore, the amount of carbon added is 1.2 times the stoichiometric requirement, and the amount added accounts for chromite 8% bentonite of iron ore powder mass, mixed with 7% flux (flux contains limestone and Na 2 CO 3 , and Na 2 CO 3 The weight ratio of limestone to limestone is 1:4), the materials are mixed and pelletized to obtain mixed wet pellets with a diameter of 10-14mm, and the dried pellets obtained after drying the mixed wet pellets are distributed into the rotary hearth furnace. The maximum temperature in the furnace is set at 1380°C. After the pellets are reduced in the furnace for 30 minutes, they are discharged from the rotary hearth furnace with a screw discharger. The pellets are piled up and leached with dilute sulfuric acid with a mass concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com