Steel used for quartering hammer piston rods, and thermal treatment method thereof

A technology for a piston rod and a breaker is applied in the field of steel for a breaker piston rod and its heat treatment process, which can solve the problems of low strength, hardness, low fatigue strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the examples.

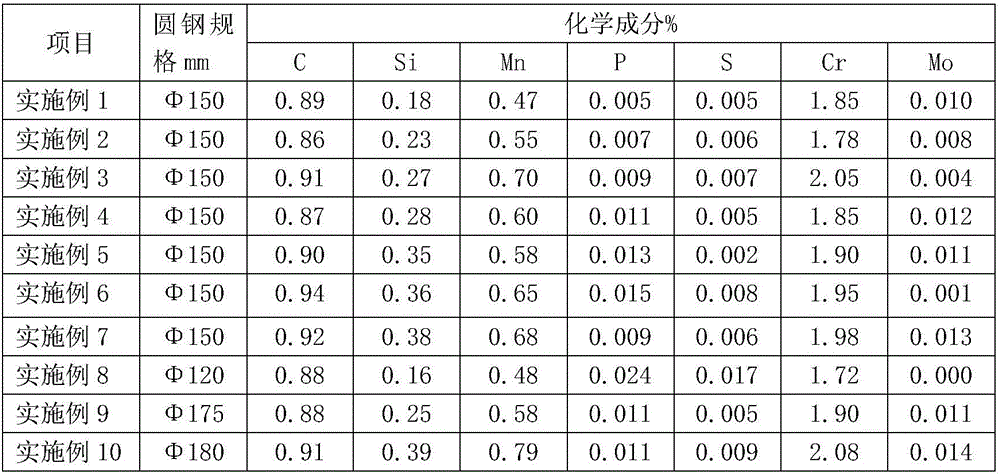

[0031] The chemical composition (smelting analysis, the rest is Fe and unavoidable impurity elements) of the steel for the piston rod of the breaking hammer of Examples 1-10 is shown in Table 1

[0032] Table 1

[0033]

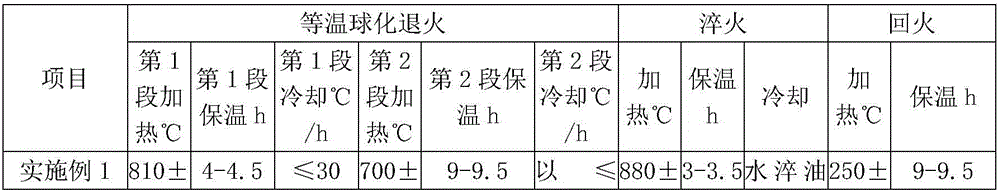

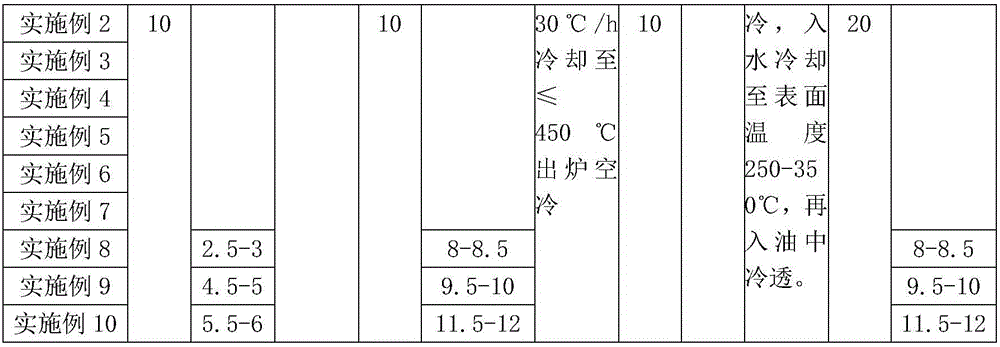

[0034] See 2 for the heat treatment process of the steel for the piston rod of the breaking hammer in Examples 1-10:

[0035] Table 2

[0036]

[0037]

[0038] The steel produced in Examples 1-10 was used as a piston rod and delivered for use. There was no deformation of the piston rod, diameter expansion, damage to the cylinder body, and no breakage, which met the requirements for the use of the breaker.

[0039] The steel breaker piston rod produced by the application is compared with the usage of 40CrNiMoA steel and GCr15 steel in the prior art, as shown in Table 3 below:

[0040]

[0041] In conjunction with the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com