Plugging brick for top opening of water-coal slurry gasification furnace and preparation process thereof

A gasifier and coal-water slurry technology, applied in the field of refractory materials, can solve the problems of reduced service life of vault bricks, mismatched furnace openings, and easy damage to vault bricks, etc., and achieves high compressive strength, corrosion resistance and Excellent flushing performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

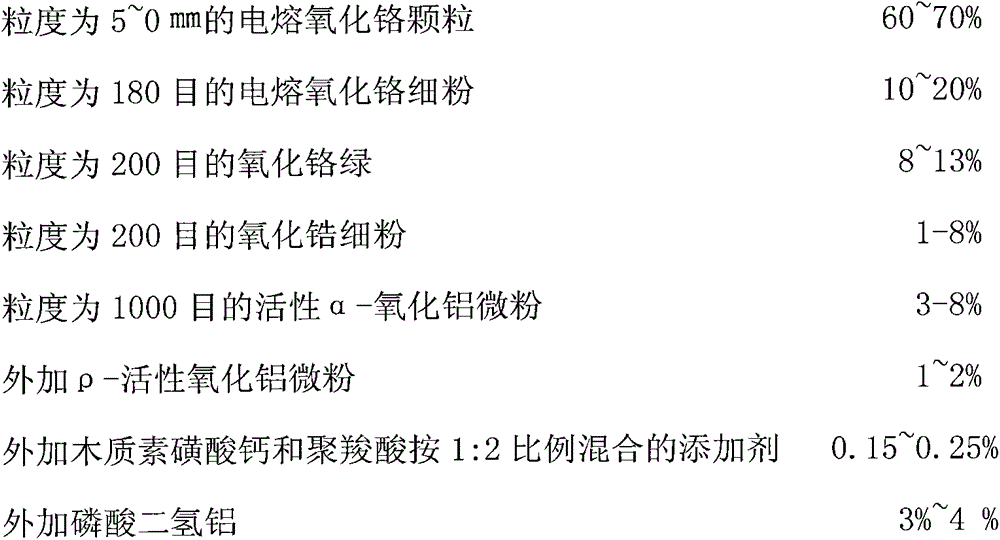

[0042] Ingredients as follows:

[0043] (1) Fused chromium oxide particles with a particle size of 5-0mm, 66%

[0044] (2) Fused chromium oxide fine powder with a particle size of 180 mesh, 14%

[0045] (3) Chrome oxide green with a particle size of 200 mesh, 10%

[0046] (4) Zirconia fine powder with a particle size of 200 mesh, 5%

[0047] (5) Activated α-alumina micropowder with a particle size of 1000 meshes, 5%

[0048] Plus:

[0049] The sum of the weight percentages of the above components is 100%, and it is preferable to additionally add the following components in weight percentages, and the calculation basis of the added amount is the sum of the weights of the above components.

[0050] (6) ρ-activated alumina powder, 1%

[0051] (7) Adding composite additives (calcium lignosulfonate and polycarboxylic acid 1: 2 ratio mixture), 0.16%

[0052] (8) Aluminum dihydrogen phosphate, 3.5%

[0053] The specific process is as follows:

[0054] (1) Pre-mixed fine powde...

Embodiment 2

[0063] Ingredients as follows:

[0064] (1) Fused chromium oxide particles with a particle size of 5-0mm, 61%

[0065] (2) Fused chromium oxide fine powder with a particle size of 180 meshes, 18%

[0066] (3) Chrome oxide green with a particle size of 200 mesh, 12%

[0067] (4) Zirconia fine powder with a particle size of 200 mesh, 4%

[0068] (5) Activated α-alumina micropowder with a particle size of 1000 meshes, 5%

[0069] Plus:

[0070] The sum of the weight percentages of the above components is 100%, and it is preferable to additionally add the following components in weight percentages, and the calculation basis of the added amount is the sum of the weights of the above components.

[0071] (6) ρ-activated alumina powder, 1.8%

[0072] (7) Adding composite additives (calcium lignosulfonate and polycarboxylic acid 1: 2 ratio mixture), 0.2%

[0073] (8) Aluminum dihydrogen phosphate, 3.8%

[0074] The specific process is as follows:

[0075] (1) Pre-mixed fine po...

Embodiment 3

[0084] Ingredients as follows:

[0085] (1) Fused chromium oxide particles with a particle size of 5-0mm, 68%

[0086] (2) Fused chromium oxide fine powder with a particle size of 180 mesh, 15%

[0087] (3) Chrome oxide green with a particle size of 200 mesh, 8%

[0088] (4) Zirconia fine powder with a particle size of 200 meshes, 6%

[0089] (5) Activated α-alumina micropowder with a particle size of 1000 meshes, 3%

[0090] Plus:

[0091] The sum of the weight percentages of the above components is 100%, and it is preferable to additionally add the following components in weight percentages, and the calculation basis of the added amount is the sum of the weights of the above components.

[0092] (6) ρ-activated alumina powder, 2%

[0093] (7) Adding composite additives (calcium lignosulfonate and polycarboxylic acid 1: 2 ratio mixture), 0.22%

[0094] (8) Aluminum dihydrogen phosphate, 3.4%

[0095] The specific process is as follows:

[0096] (1) Pre-mixed fine powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com