Preparation method of Q420-grade hot-rolling weather-resistant angle steel

An angle steel and weather-resistant technology, applied in the field of metallurgy, can solve the problems of increased cost, cracking, weather-resistant cold-formed angle steel transmission towers cannot be deployed on a large scale, and achieve the effect of offsetting harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of Q420 grade hot-rolled weather-resistant angle steel, comprising the following steps:

[0025] Steel billet smelting: steel billets are made by deep desulfurization of molten iron, converter smelting, slag-retaining tapping and argon blowing. During the smelting process, fine grained alloy elements are added to the billets.

[0026] Billet rolling: start rolling temperature ≥ 1120°C, finish rolling temperature: 800°C-840°C;

[0027] Billet cooling: the cooling method is air cooling to obtain Q420 hot-rolled weather-resistant angle steel;

[0028] Straightening angle steel: straightening temperature ≤ 60 ℃.

[0029] Wherein, the billet pressing step includes a rough rolling stage and a finish rolling stage.

[0030] The high-temperature recrystallization zone rolling in the rough rolling stage is mainly to obtain uniformly refined austenite grains through repeated rolling and repeated recrystallization of the heated and coa...

Embodiment 1

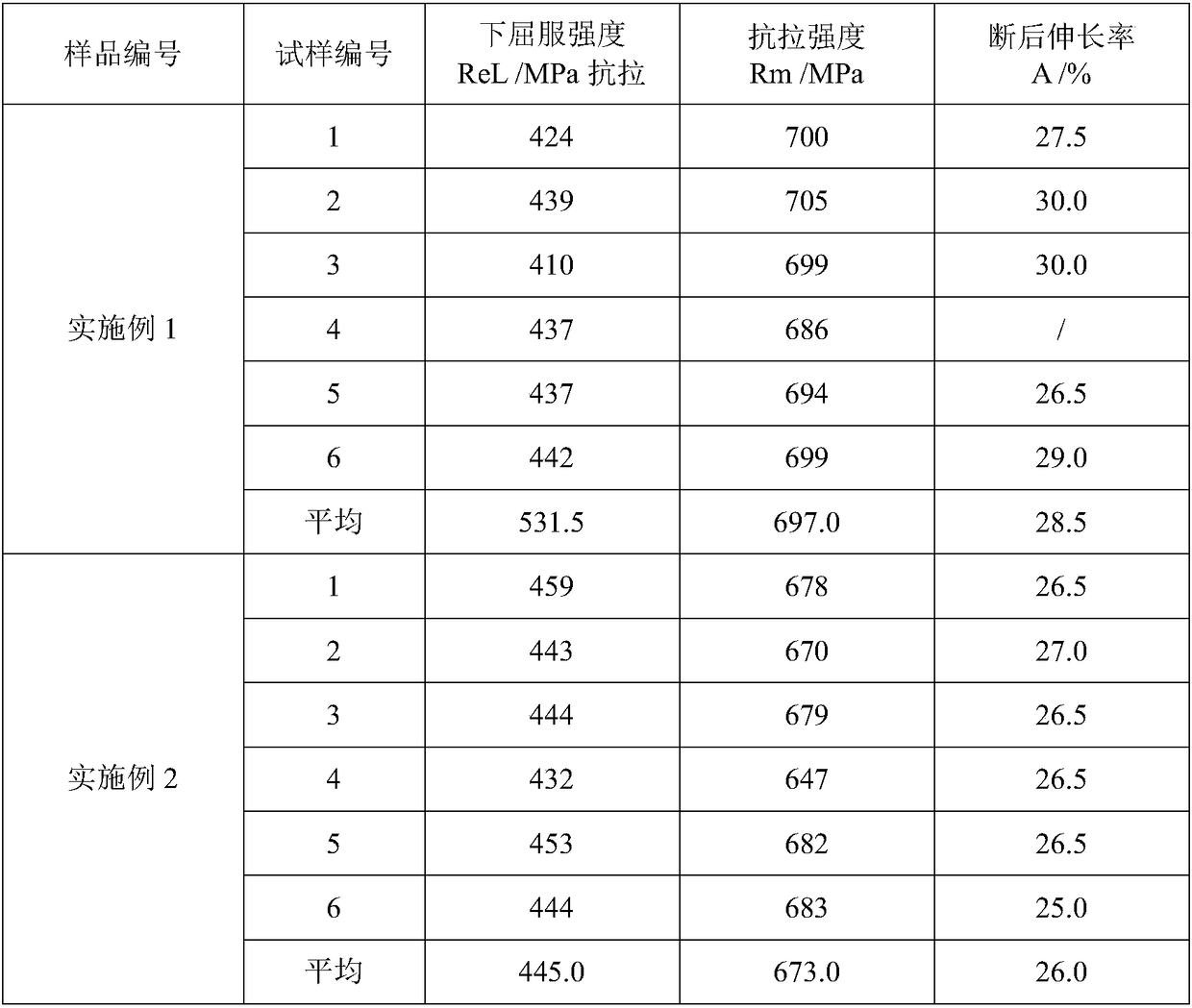

[0039] The normal temperature tensile test results of the angle steel made by embodiment 1 and embodiment 2 are shown in table 2

[0040]

[0041] Table 2

[0042] The angle steel impact test results of two embodiments are shown in Table 3

[0043]

[0044] table 3

[0045] The angle steel bending test results of two embodiments are shown in Table 4

[0046]

[0047] Table 4

[0048] The angle steel metallographic structure of two embodiments is shown in Table 5

[0049] Sample serial number

[0050] table 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com