Method for reuse of steel sheet scrap

a steel plate and scrap technology, applied in the direction of process efficiency improvement, etc., can solve the problems of reducing the ease of casting, the inability to use cast iron structural parts, and the inability to meet the requirements of casting, so as to enhance the mechanical strength and enhance the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

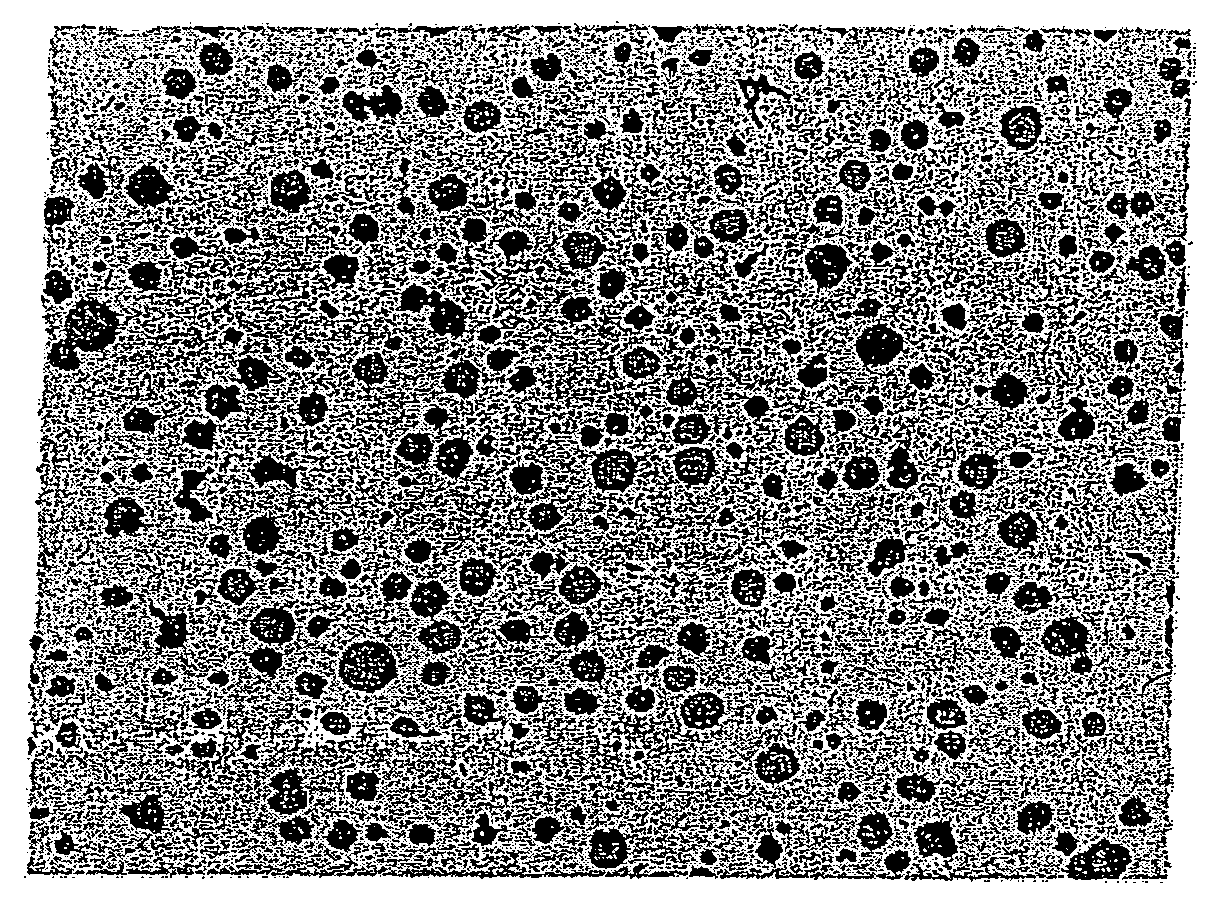

Image

Examples

Embodiment Construction

[0023] In the recycling method of scrap steel plate of the present invention, scraps of high-tensile steel plates are collected together with scraps of ordinary steel plates in a batch collecting process, first.

[0024] The scraps of high-tensile steel plates collected are scrap steel plates left over after the pressing of the high-tensile steel plate (high-tensile plate), including, for example, scrap steel plates left over after the pressing of a shell body and a shell plate of an automobile employing high-tensile steel plates.

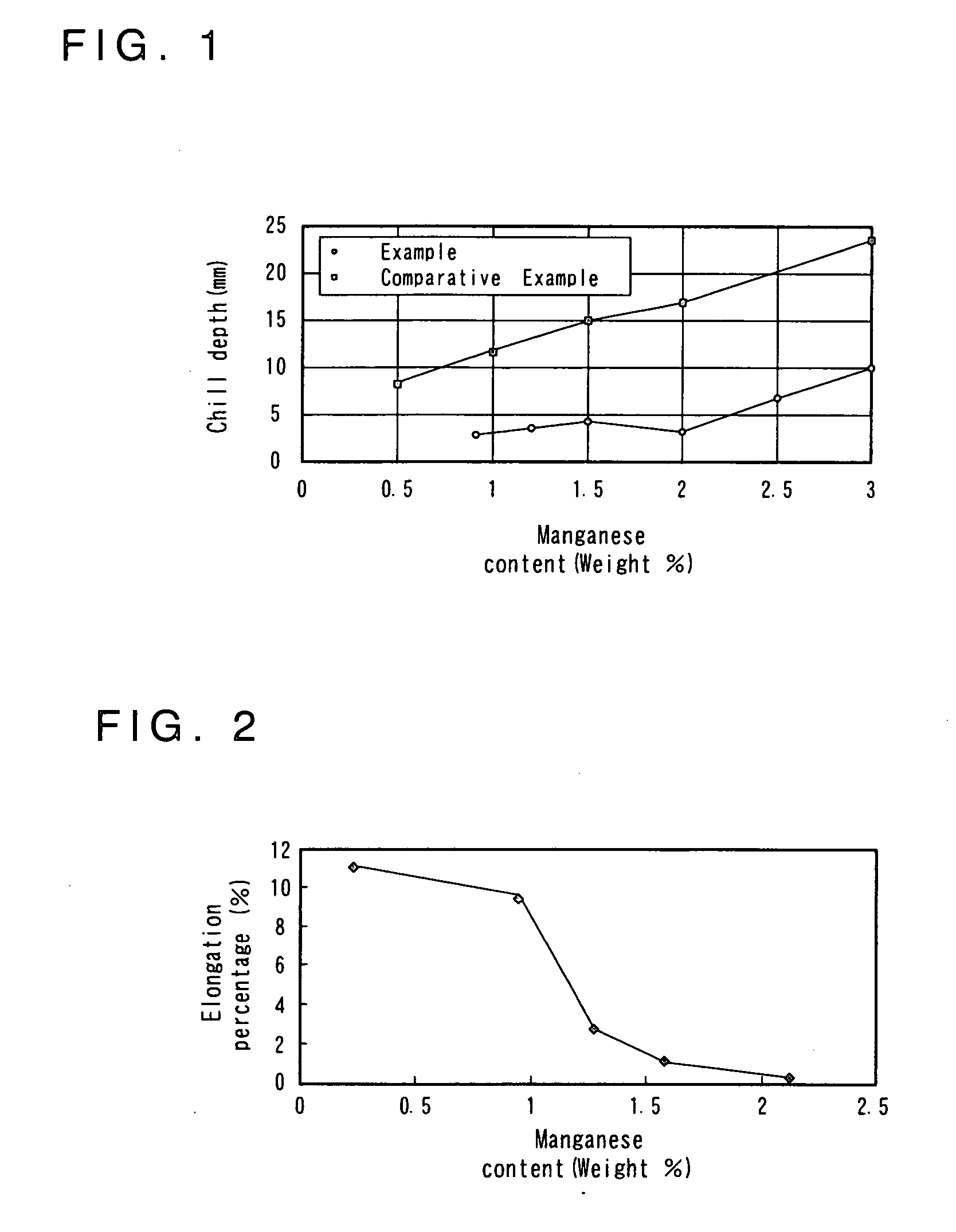

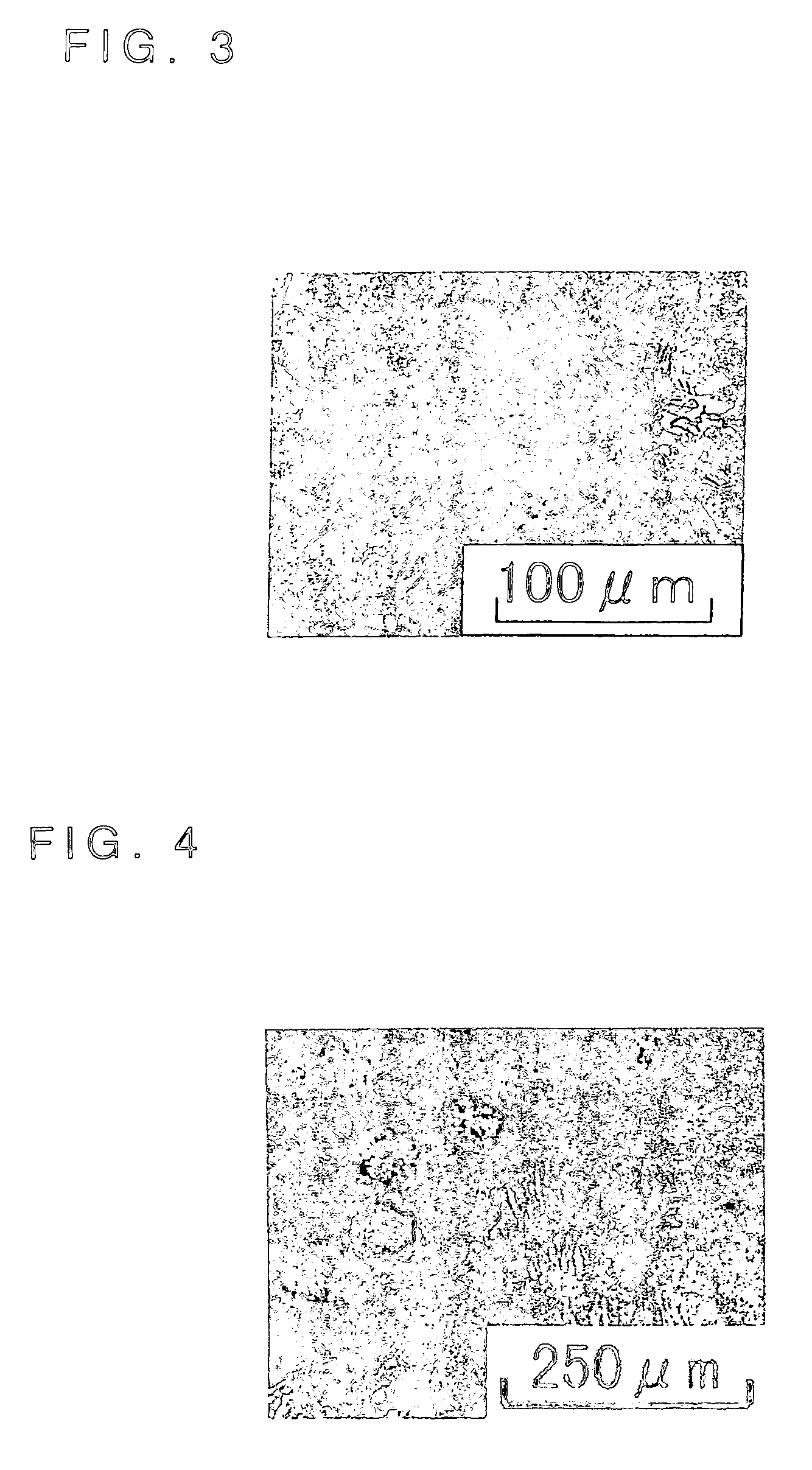

[0025] The high-tensile steel plate is made of alloyed steel which is increased in strength by addition of chromium and other material and usually has a tensile strength of 340MPa or more, containing impurities such as manganese and phosphorous. For example, this high-tensile steel plate comprises usually 0.5 to 2.0 weight % manganese, usually 0.02 to 0.1 weight % phosphorous, and usually 0.05 to 1.0 weight % chromium.

[0026] The scraps of ordinary steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com