Austenitic stainless steel

A technology of austenitic stainless steel and chemical composition, applied in the field of austenitic stainless steel for deep drawing, can solve the problem of saving without advantages, and achieve the effects of price reduction, good mechanical properties, and good production and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The austenitic stainless steel of the present invention can be smelted in a non-vacuum induction furnace or an electric arc furnace. The thermal processing (forging or hot rolling) temperature range of the ingot is 1130-1200°C, and the solution heat treatment temperature is 1050-1115°C.

[0024] The austenitic stainless steel of the present invention mainly produces hot-rolled strips, cold-rolled strips, hot-rolled plates and bars, and the like.

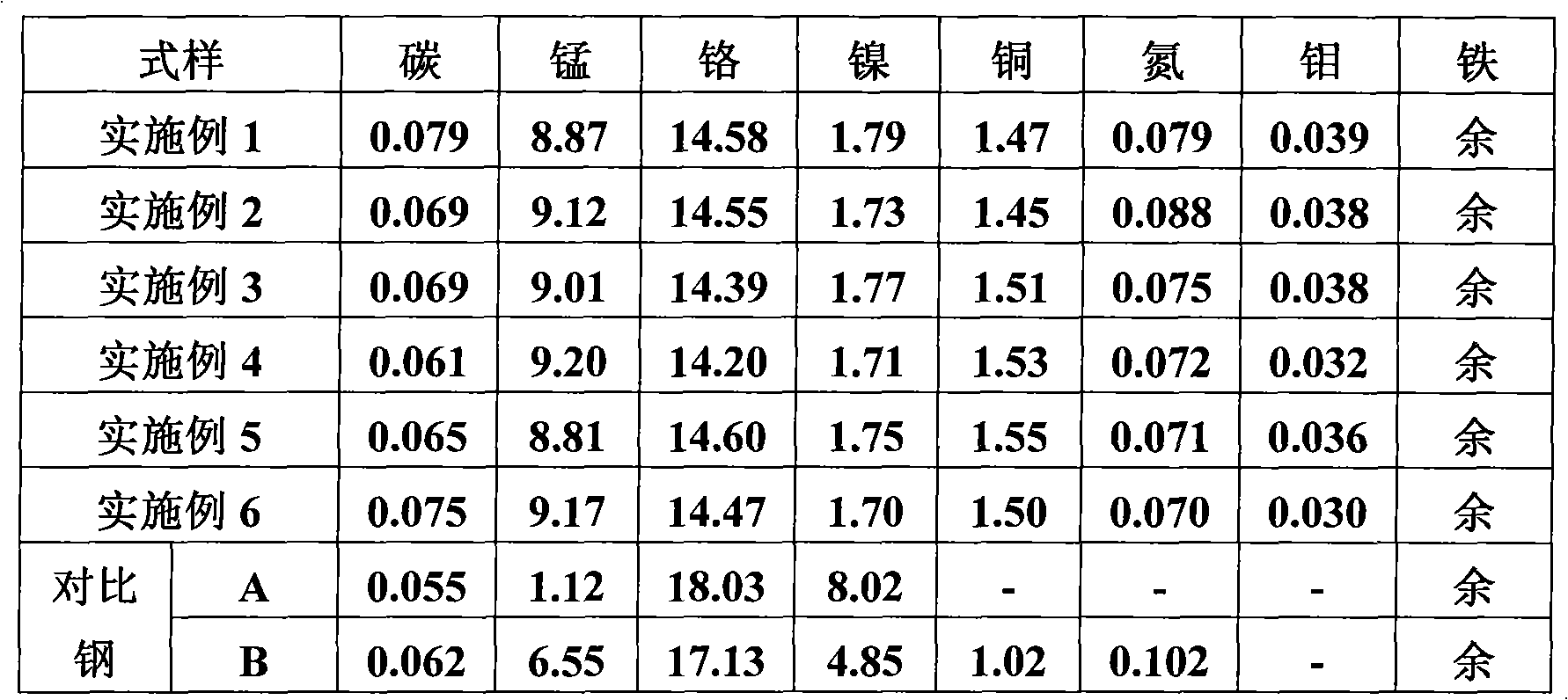

[0025] Six examples of the austenitic stainless steel of the present invention are summarized in Table 1, and the chemical composition comparison of the sample of the austenitic stainless steel of the present invention and the contrast steel is also given in this table, wherein: the contrast steel A is 304, B is 201.

[0026] Table I

[0027]

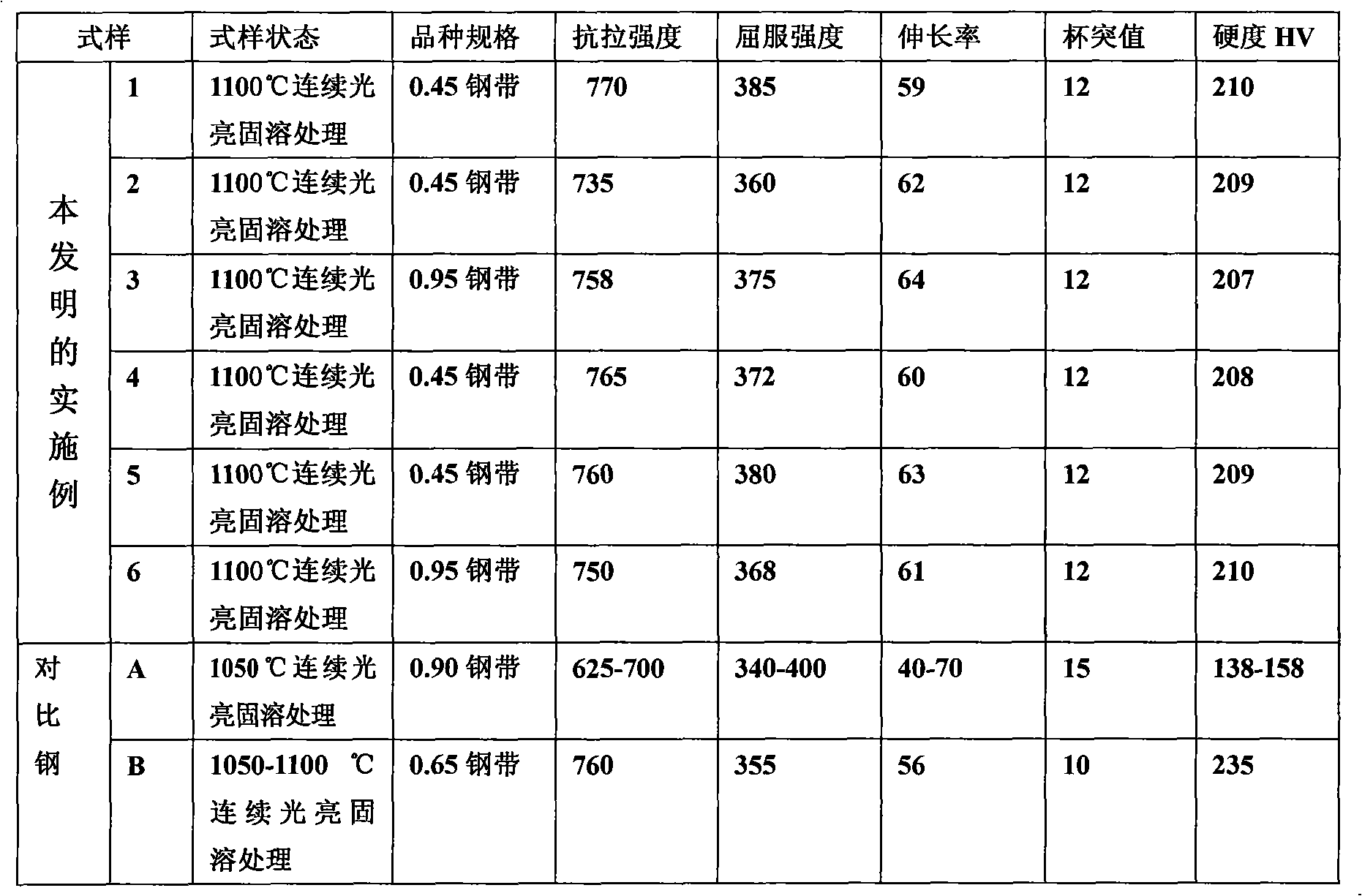

[0028] The excellent mechanical properties and deep drawing properties of the austenitic stainless steels obtained in the above six embodiments of the present invention are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com