Treatment system and treatment method of ferrous manganese ore

A processing system and ferromanganese ore technology, which is applied in the field of energy and metallurgy, can solve problems such as high cost, long process, and serious environmental pollution, and achieve the effects of high recovery rate, high manganese content, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The ferromanganese ore used in the present embodiment has a composition of: TFe25.28%, TMn14.35%; the reducing agent used is coal powder, and the mass percentage of its fixed carbon is 82.63%, and the mass percentage of air-dry basis ash The content is 8.17%; the reduced coal used is also the coal powder; the additive used is calcium oxide.

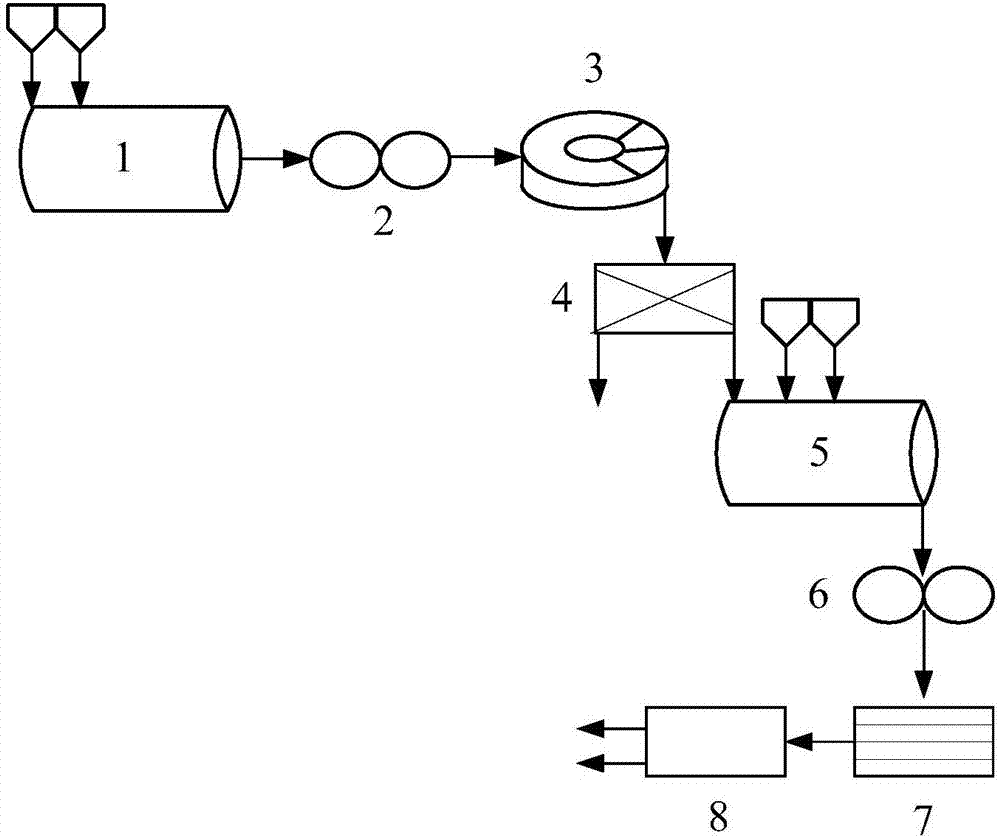

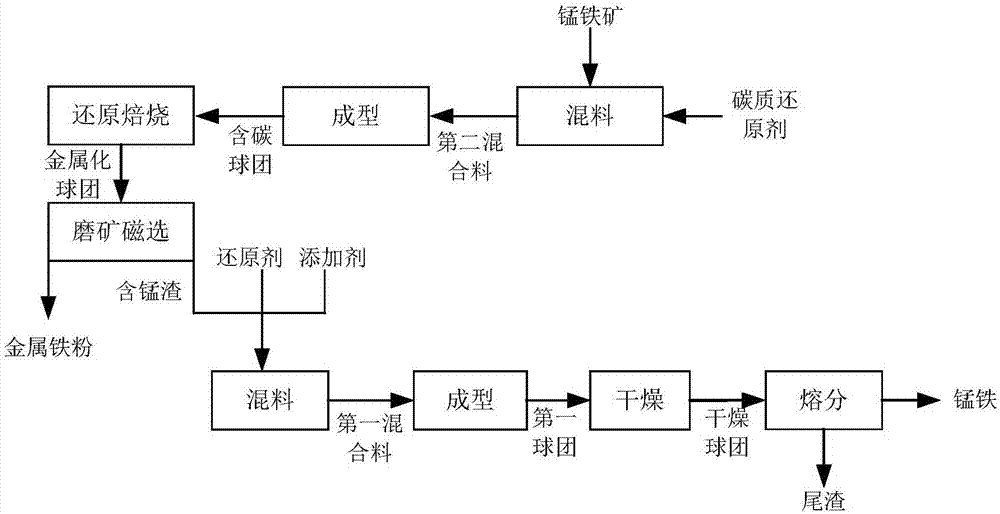

[0063] This embodiment adopts figure 1 The system shown and image 3 The process flow shown for manganese ore is as follows:

[0064] The manganese ore and coal powder are sent into the second mixture 1 according to the mass ratio of 100:20 and mixed evenly to obtain the second mixture.

[0065] The second mixture is sent to the second molding device 2 for molding to obtain carbon-containing pellets.

[0066] The carbon-containing pellets are sent to the reduction device 3 for reduction roasting, and are reduced at 1100° C. for 20 minutes to obtain metallized pellets.

[0067] The metallized pellets are sent to the grinding dev...

Embodiment 2

[0072] The ferromanganese ore used in the present embodiment has a composition of: TFe25.28%, TMn14.35%; the reducing agent used is H 2 and CO mixed gas, in which the mixed gas (H 2 +CO) volume fraction ≥ 70%, the mass percentage of fixed carbon in the reduced coal used is 76%; the additive used is magnesium oxide.

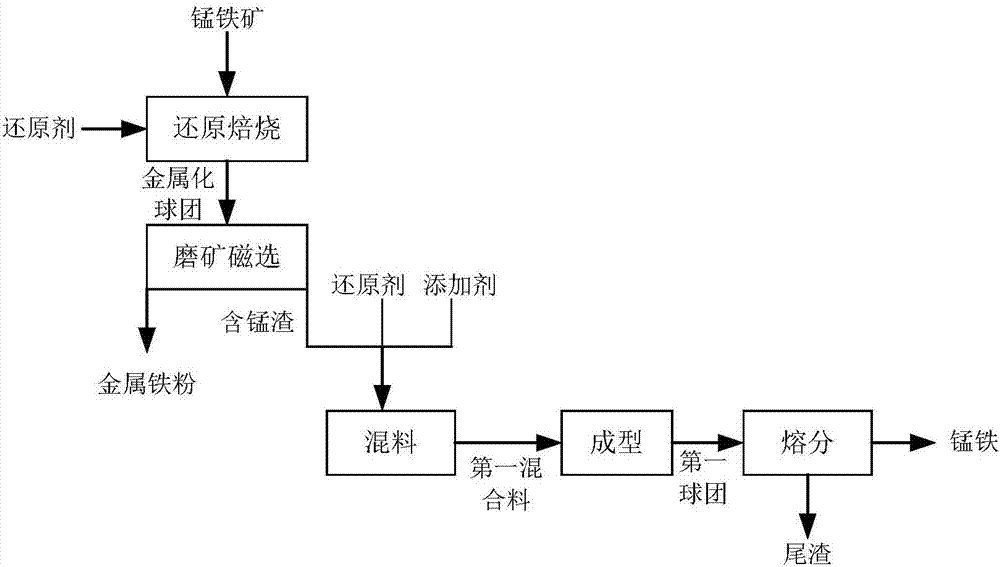

[0073] This embodiment adopts figure 1 The system shown and figure 2 The process flow shown for manganese ore is as follows:

[0074] The manganese ore is sent to the reduction device 3, and the above-mentioned mixed gas is passed into the reduction device 3, the manganese ore is reduced and roasted, and the manganese ore is reduced at 800°C for 90 minutes to obtain metallized pellets.

[0075] The metallized pellets are sent to the grinding device 4 for grinding and magnetic separation to obtain metal iron powder with TFe91.18% and manganese slag with TFe9.06% and TMn32.71%.

[0076] The manganese slag, reduced coal, and magnesium oxide are sent to the first...

Embodiment 3

[0080] The ferromanganese ore used in the present embodiment has a composition of: TFe18.15%, TMn17.97%; the reductant used is coal powder, and the mass percentage of its fixed carbon is 79.50%, and the mass percentage of air-dry basis ash The content is 9.78%; the reduced coal used is also the coal powder; the additive used is a mixture of calcium carbonate and magnesium carbonate.

[0081] This embodiment adopts figure 1 The system shown and image 3 The process flow shown for manganese ore is as follows:

[0082] The manganese ore and coal powder are sent into the second mixture 1 according to the mass ratio of 100:19.6 and mixed evenly to obtain the second mixture.

[0083] The second mixture is sent to the second molding device 2 for molding to obtain carbon-containing pellets.

[0084] The carbon-containing pellets are sent to the reducing device 3 for reduction roasting, and are reduced at 900° C. for 60 minutes to obtain metallized pellets.

[0085] The metallized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com