Method for removing manganese from acidic molybdenum precipitation wastewater

A vanadium-precipitated wastewater and acidic technology, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems that sediment and wastewater can no longer be effectively used, cannot be further separated, and cannot be directly applied. Achieve good social and economic benefits, low equipment requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

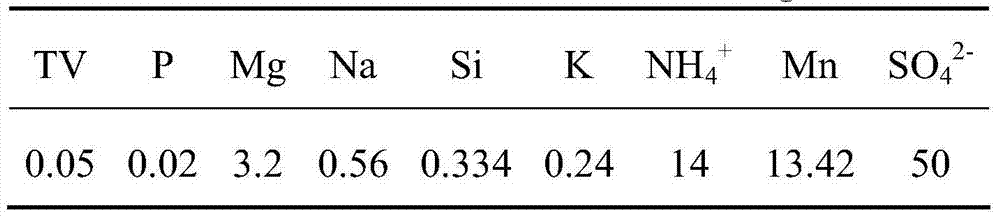

[0037]Add 1000mL of acidic vanadium-precipitation wastewater with the components listed in Table 1 to a 2000mL clean beaker, stir and keep the temperature of the acidic vanadium-precipitation wastewater at 25°C, use calcium oxide to adjust the pH of the acidic vanadium-precipitation wastewater to 5.0, and then add 0.24 mol of ammonium oxalate was reacted for 30 minutes, cooled and settled for 30 minutes, and filtered to obtain manganese oxalate precipitate and supernatant. After testing, the manganese ion in the obtained supernatant was less than 0.05g / L. Heat and concentrate the obtained supernatant at 90°C so that the concentration of ammonium sulfate in the concentrated supernatant is greater than 300g / L, then cool and crystallize at 0°C to obtain ammonium sulfate, and the obtained condensed water can be directly used for calcification of vanadium slag Leaching of roasted clinker.

example 2

[0039] Add 1000mL of acidic vanadium precipitation wastewater with the components listed in Table 1 to a 2000mL clean beaker, stir and keep the temperature of the acidic vanadium precipitation wastewater at 60°C, use ammonium carbonate to adjust the pH value of the acidic vanadium precipitation wastewater to 7.0, and then add 0.36 mol of ammonium oxalate was reacted for 120 minutes, cooled and settled for 60 minutes, and filtered to obtain manganese oxalate precipitate and supernatant. After testing, the manganese ion in the obtained supernatant was less than 0.05g / L. Heat and concentrate the obtained supernatant at 100°C so that the concentration of ammonium sulfate in the concentrated supernatant is greater than 300g / L, then cool and crystallize at 10°C to obtain ammonium sulfate, and the obtained condensed water can be directly used for calcification of vanadium slag Leaching of roasted clinker.

example 3

[0041] In the 2000mL clean beaker, add 1000mL acidic vanadium precipitation wastewater with the composition listed in Table 1, stir and keep the temperature of the acidic vanadium precipitation wastewater at 50°C, use calcium hydroxide to adjust the pH value of the acidic vanadium precipitation wastewater to 6.0, and then Add 0.30 mol of ammonium oxalate, react for 100 minutes, cool and settle for 40 minutes, and filter to obtain manganese oxalate precipitate and supernatant. After testing, the manganese ion in the obtained supernatant was less than 0.05g / L. Heat and concentrate the obtained supernatant at 95°C so that the ammonium sulfate concentration in the concentrated supernatant is greater than 300g / L, then cool and crystallize at 5°C to obtain ammonium sulfate, and the obtained condensed water can be directly used for vanadium slag calcification Leaching of roasted clinker.

[0042] In summary, the present invention uses chemical methods to remove manganese from acidic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com