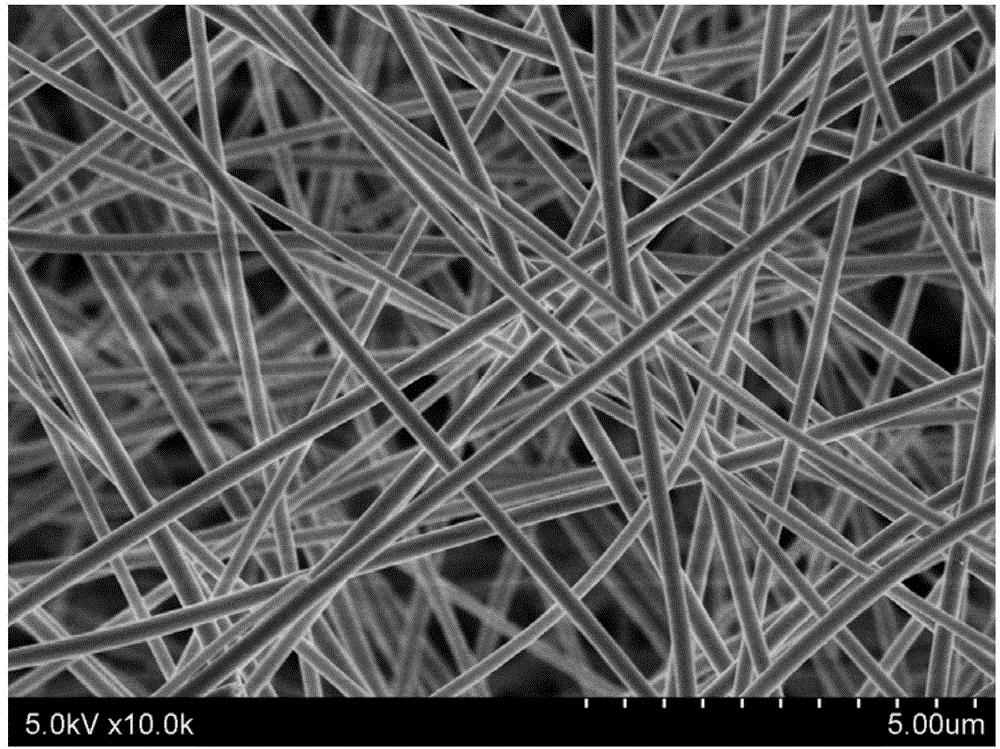

Flexible manganese oxide nano fibrous membrane and preparation method thereof

A technology of nanofiber membrane and manganese oxide, which is applied in the field of new materials, can solve the problems of complex preparation process, low fiber yield and easy breakage, and achieve the effect of simple preparation process, high fiber yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

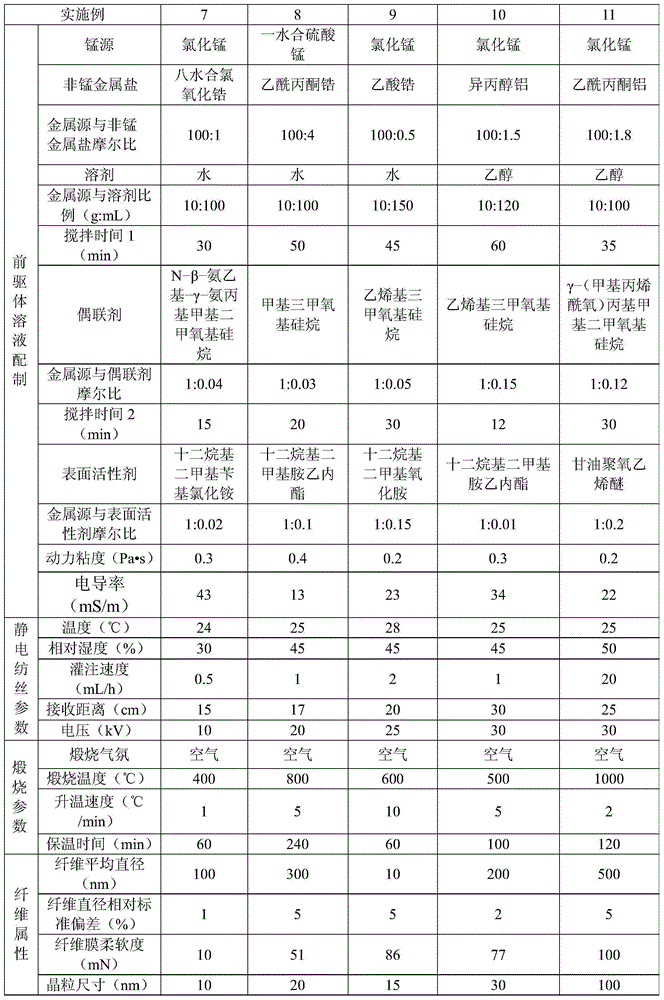

Examples

Embodiment 1

[0048] A method for preparing a flexible manganese oxide nanofiber membrane, the specific steps are:

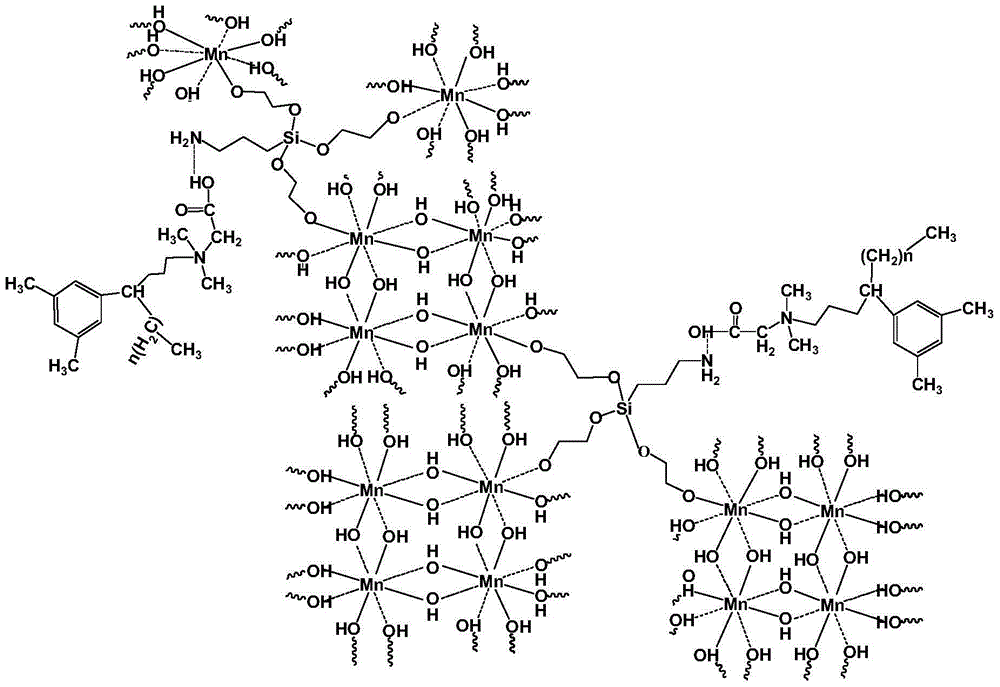

[0049] The first step: dissolve manganese chloride and zirconium chloride in water, the molar ratio of manganese chloride to zirconium chloride is 100:1, add coupling agent γ-aminopropyltriethoxysilane after stirring for 60min, and then Add surfactant dodecyldimethylbenzyl ammonium chloride after continuous stirring for 30min, wherein the ratio of manganese chloride to water is 10g:60mL, manganese chloride and coupling agent γ-aminopropyltriethoxy The molar ratio of silane is 1:0.08, and the molar ratio of manganese chloride and surfactant dodecyldimethylbenzyl ammonium chloride is 1:0.05; mix uniformly to make a uniform and stable three-dimensional network structure with interpenetrating The molecular chain precursor solution has a dynamic viscosity of 0.1Pa s and a conductivity of 10mS / m. Its structural formula is as follows:

[0050]

[0051] The second step: the above...

Embodiment 2

[0054] A method for preparing a flexible manganese oxide nanofiber membrane, the specific steps are:

[0055] Step 1: Dissolve manganese acetate and aluminum chloride hexahydrate in water. The molar ratio of manganese acetate and aluminum chloride hexahydrate is 100:2. After stirring for 45 minutes, add coupling agent vinyltrimethoxysilane and continue stirring After 15min, add surfactant dodecyldimethyl betaine, wherein the ratio of manganese acetate to water is 10g:80mL, and the molar ratio of manganese acetate to coupling agent vinyltrimethoxysilane is 1:0.06, The molar ratio of manganese chloride and surfactant dodecyl dimethyl betaine is 1:0.08; mix uniformly to make a uniform and stable precursor solution with interpenetrating three-dimensional network molecular chains, and its dynamic viscosity is 0.4 Pa·s, the conductivity is 15 mS / m, and the precursor solution has molecular chains with an interpenetrating three-dimensional network structure similar to that of Example ...

Embodiment 3

[0059] A method for preparing a flexible manganese oxide nanofiber membrane, the specific steps are:

[0060] Step 1: Dissolve manganese carbonate and aluminum powder in formic acid, the molar ratio of manganese carbonate and aluminum powder is 100:2.5, add coupling agent N-β-aminoethyl-γ-aminopropylmethyl after stirring for 30 minutes Dimethoxysilane, after continuing to stir for 30min, add surfactant sodium dodecylbenzenesulfonate, wherein the ratio of manganese carbonate to water is 10g:100mL, manganese carbonate and coupling agent N-β-aminoethyl- The molar ratio of γ-aminopropylmethyldimethoxysilane is 1:0.1, and the molar ratio of manganese carbonate and surfactant sodium dodecylbenzenesulfonate is 1:0.07; mix uniformly to make a uniform and stable product with The precursor solution of interpenetrating three-dimensional network molecular chains has a dynamic viscosity of 0.2 Pa·s and an electrical conductivity of 14 mS / m. The precursor solution has molecular chains of in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com