High-nickel-series and full-concentration gradient lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery, full concentration gradient technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of safety and poor cycle performance of positive electrode materials of ternary nickel-cobalt manganate lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a high nickel-based full-concentration gradient lithium-ion battery positive electrode material, comprising the following steps:

[0037]Step 1: Prepare solution A and solution B containing nickel salt, cobalt salt and manganese salt with a total concentration of 1 to 4 mol / L respectively; the ratio of nickel, cobalt and manganese in the solution A is preferably: 0.7~ 1.0: 0-0.5: 0-0.5, more preferably 0.8-0.85: 0.075-0.2: 0.1-0.2; the ratio of nickel, cobalt and manganese in the solution B is preferably: 0.1-0.5: 0-0.5 : 0.25~1.0, more preferably 0.4~0.6: 0.2: 0.2~0.4; the nickel salt, cobalt salt and manganese salt are not particularly limited, and the nickel salt is preferably nickel sulfate, nickel hydrochloride, nickel nitrate and acetic acid One or more of nickel salts; the cobalt salt is preferably one or more of cobalt sulfate, cobalt hydrochloride, cobalt nitrate and cobalt acetate; the manganese salt ...

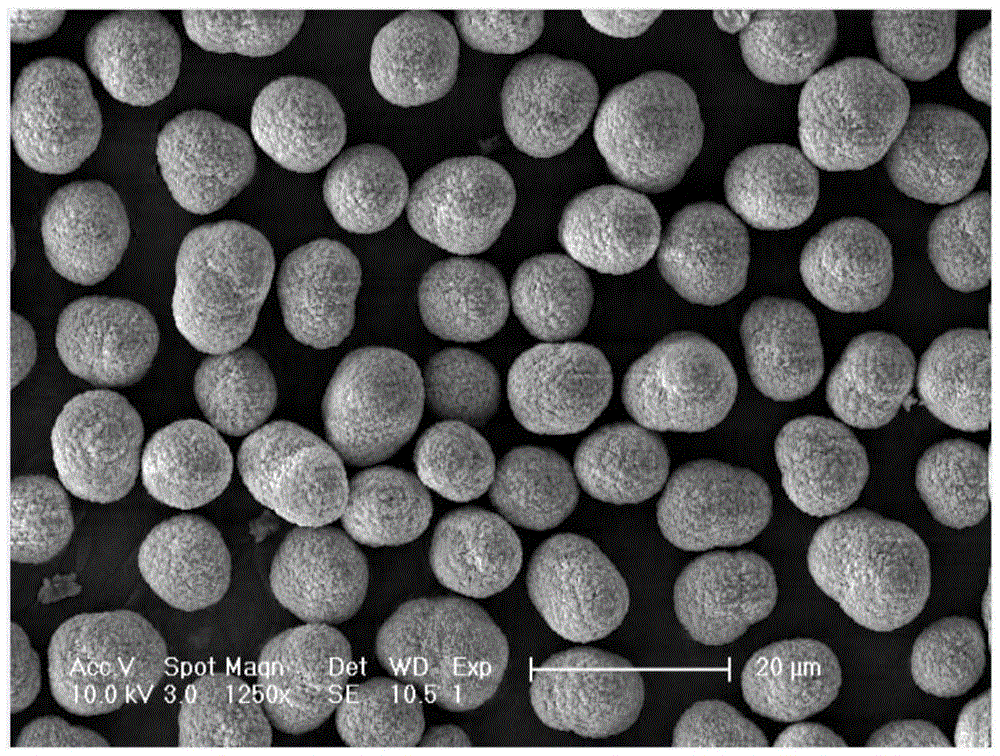

Embodiment 1

[0043] The raw materials used in this experiment are nickel sulfate, cobalt sulfate, and manganese sulfate as metal salts, sodium hydroxide as alkali solution, ammonia water as complexing agent, and lithium hydroxide as lithium source. First prepare solution A with a ratio of 8:1:1 of nickel, cobalt and manganese with a total concentration of 2 mol / L, solution B with a ratio of 4:2:4, and prepare 4 mol / L of sodium hydroxide at the same time solution and 10mol / L ammonia water, the prepared solution B was added to solution A at a flow rate of 5L / h and mixed evenly, and the well-mixed solution A, sodium hydroxide solution and ammonia water were added at a flow rate of 10L / h at the same time In the reaction kettle, control the pH value to 11.0, the reaction temperature is 50°C, and the stirring speed is 300r / min. After the simultaneous addition of solution A and solution B is completed, stop the dripping of the alkali solution and complexing agent at the same time, and continue sti...

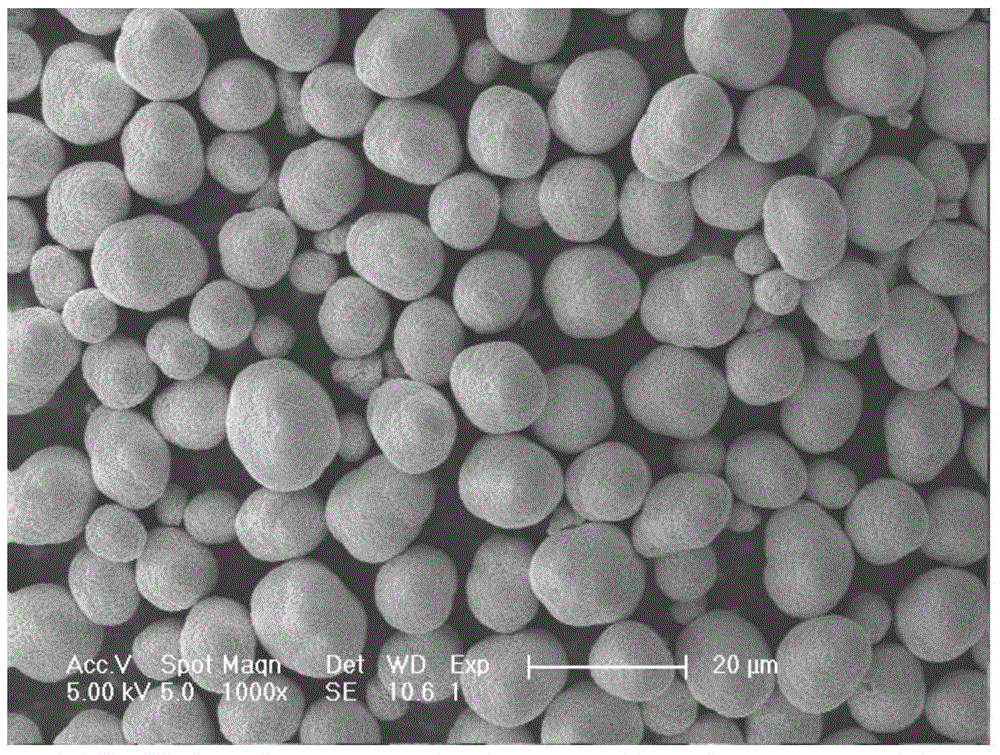

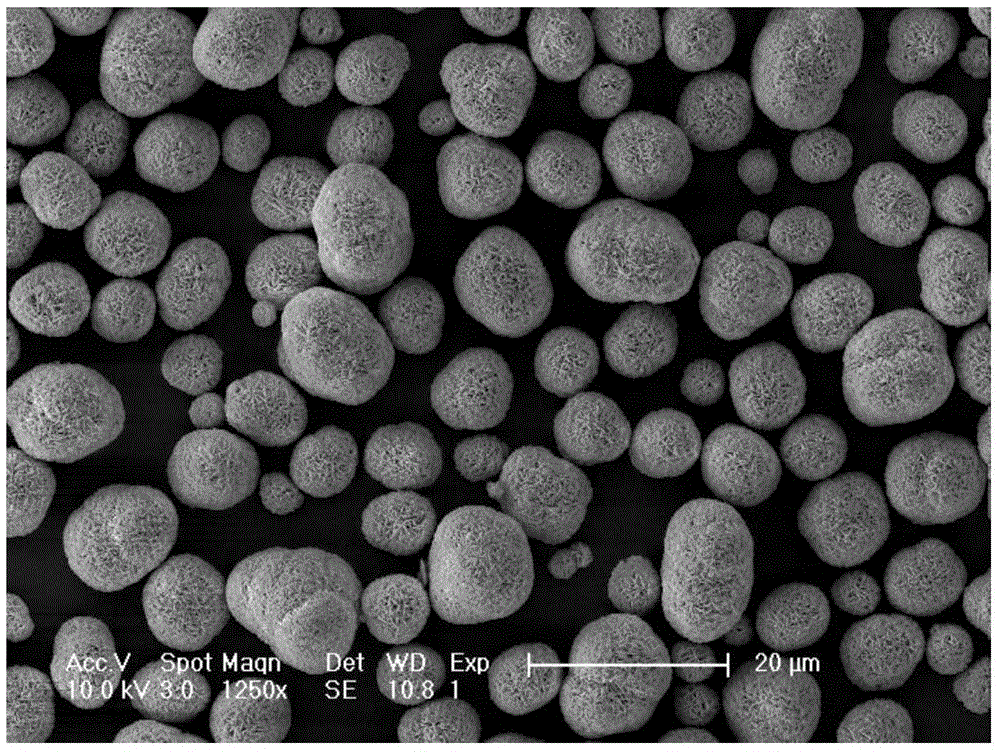

Embodiment 2

[0049] The raw materials used in this experiment are nickel chloride, cobalt chloride, and manganese chloride as metal salts, lithium hydroxide as the alkali solution, ammonia water and disodium edetate as the complexing agent, and lithium carbonate as the lithium source. First prepare solution A with a ratio of 0.85:0.075:0.075 of nickel, cobalt and manganese with a total concentration of 2mol / L, solution B with an element ratio of 0.5:0.2:0.3, and prepare 4mol / L of sodium hydroxide at the same time solution and 10mol / L ammonia water and disodium edetate solution, the prepared solution B was added to the solution A at a flow rate of 5L / h and mixed uniformly, the uniformly mixed solution A, sodium hydroxide solution, Ammonia water and disodium edetate solution were added into the reaction kettle at the same time at a flow rate of 10L / h, the pH value was controlled at 12.0, the reaction temperature was 55°C, and the stirring speed was 1200r / min. After the addition is finished, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com