Non-oriented electrical steel for new energy vehicle and manufacture method thereof

A technology for new energy vehicles and grain-oriented electrical steel, which is applied in the field of non-oriented electrical steel for new energy vehicles and its production, can solve the problem that the high magnetic induction requirements of non-oriented silicon steel for new energy vehicles cannot be met, and the loss value of magnets cannot meet the requirements of new energy vehicles. Automobile use requirements, inability to meet the low iron loss requirements of non-oriented silicon steel, etc., to achieve the effect of eliminating surface corrugation defects, reducing high-temperature coiling and normalization processes, and low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

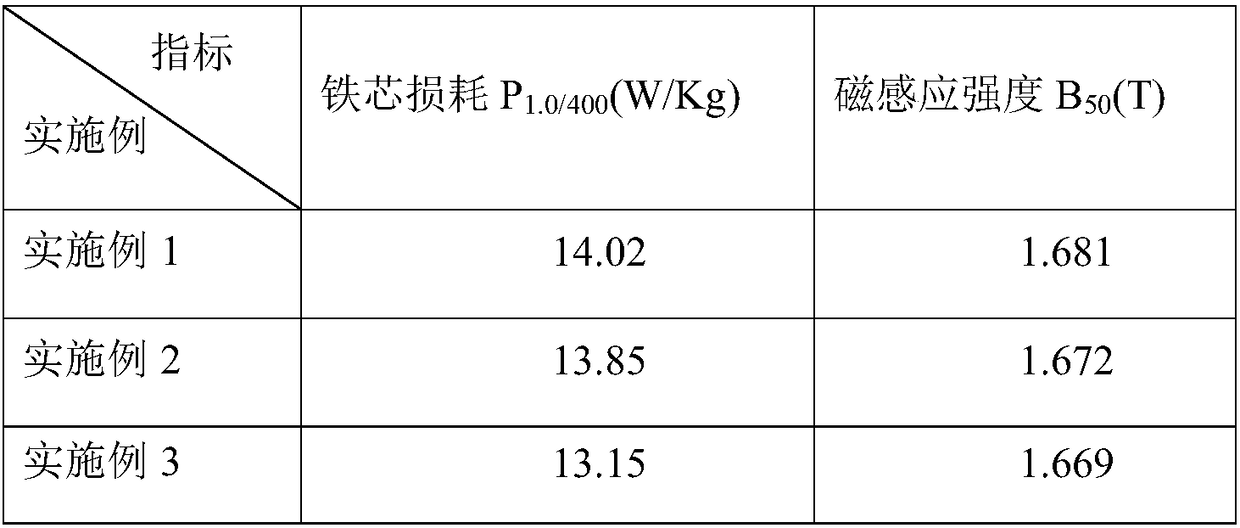

Embodiment 1

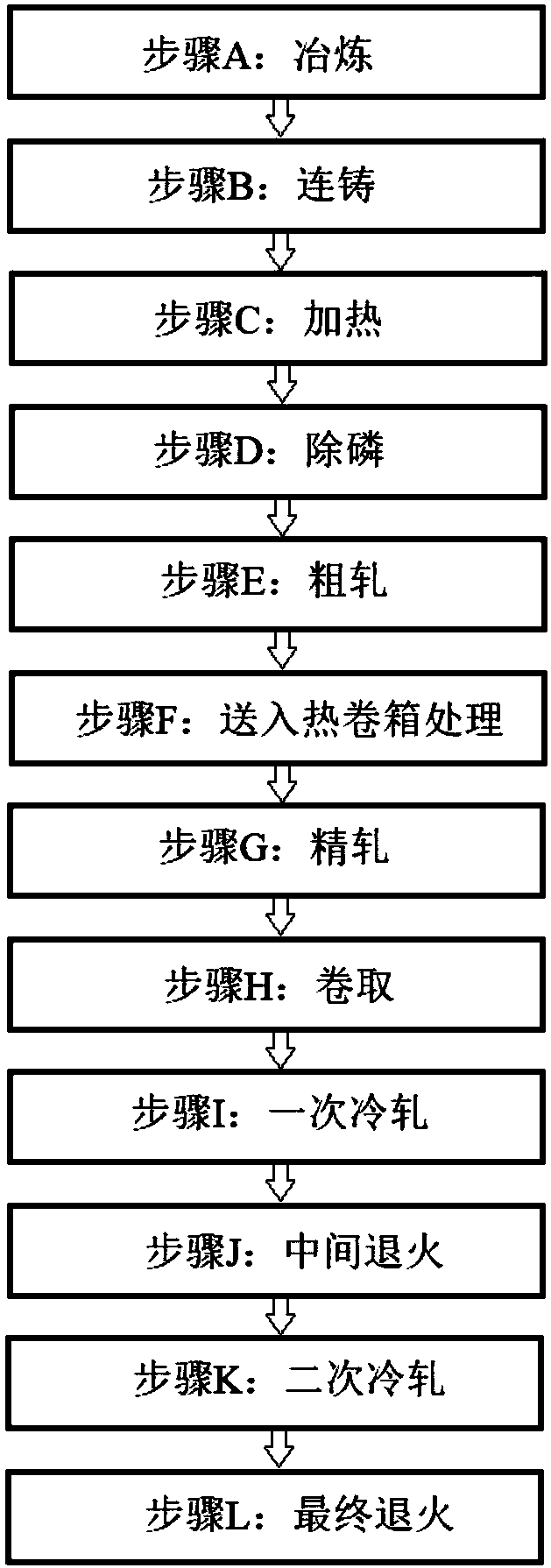

[0072] The production method of the non-oriented electrical steel for new energy vehicles of the present embodiment comprises the following steps:

[0073] Step A: smelting;

[0074] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0075] Si: 3.0%, Al: 2.0%, Mn: 2.0%, S: 15ppm, O: 20ppm, C: 10ppm, N: 17ppm, Ti: 8ppm, [S+O+C+N+Ti]≤80ppm, [ Sn+Sb]: 0.03%, [La+Ce+Nd]: 0.002%, the balance is Fe and other impurity elements;

[0076] Add rare earth elements 1 minute after RH refining and alloying, and stir after adding rare earth elements for 3.5 minutes;

[0077] Step B: continuous casting;

[0078] In the continuous casting process of step B, the casting speed is controlled to be 0.6 m / min during continuous casting, and a slab with a thickness of 220 mm is obtained through continuous casting; ele...

Embodiment 2

[0099] The production method of the non-oriented electrical steel for new energy vehicles of the present embodiment comprises the following steps:

[0100] Step A: smelting;

[0101] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0102] Si: 3.5%, Al: 1.5%, Mn: 1.5%, S: 12ppm, O: 15ppm, C: 10ppm, N: 15ppm, Ti: 5ppm, Sn: 0.05%, La: 0.005%, the balance is Fe and Other impurity elements;

[0103] Add rare earth elements 2 minutes after RH refining and alloying, and stir after adding rare earth elements for 3 minutes;

[0104] Step B: continuous casting;

[0105] In the continuous casting process of step B, the casting speed is controlled to be 1.0 m / min during continuous casting, and a slab with a thickness of 250mm is obtained through continuous casting; electromagnetic stirring is used in the...

Embodiment 3

[0126] The production method of the non-oriented electrical steel for new energy vehicles of the present embodiment comprises the following steps:

[0127] Step A: smelting;

[0128] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0129] Si: 4.0%, Al: 1.0%, Mn: 1.0%, S: 18ppm, O: 12ppm, C: 10ppm, N: 15ppm, Ti: 5ppm, Sb: 0.1%, [La+Ce]: 0.1%, Yu The amount is Fe and other impurity elements;

[0130] Add rare earth elements 2 minutes after RH refining and alloying, and stir after adding rare earth elements for 4 minutes;

[0131] Step B: continuous casting;

[0132] In the continuous casting process of step B, the casting speed is controlled to be 2.0 m / min during continuous casting, and a slab with a thickness of 300 mm is obtained through continuous casting; electromagnetic stirring is used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com