Method for lower-temperature sintering to prepare acid and alkali-resistant titanium dioxide ceramic ultrafiltration membrane

A ceramic ultrafiltration membrane, titanium dioxide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of reducing the sintering temperature and reducing the physical and chemical properties of the ceramic membrane, reducing the preparation cost and reducing the The effect of energy consumption and good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

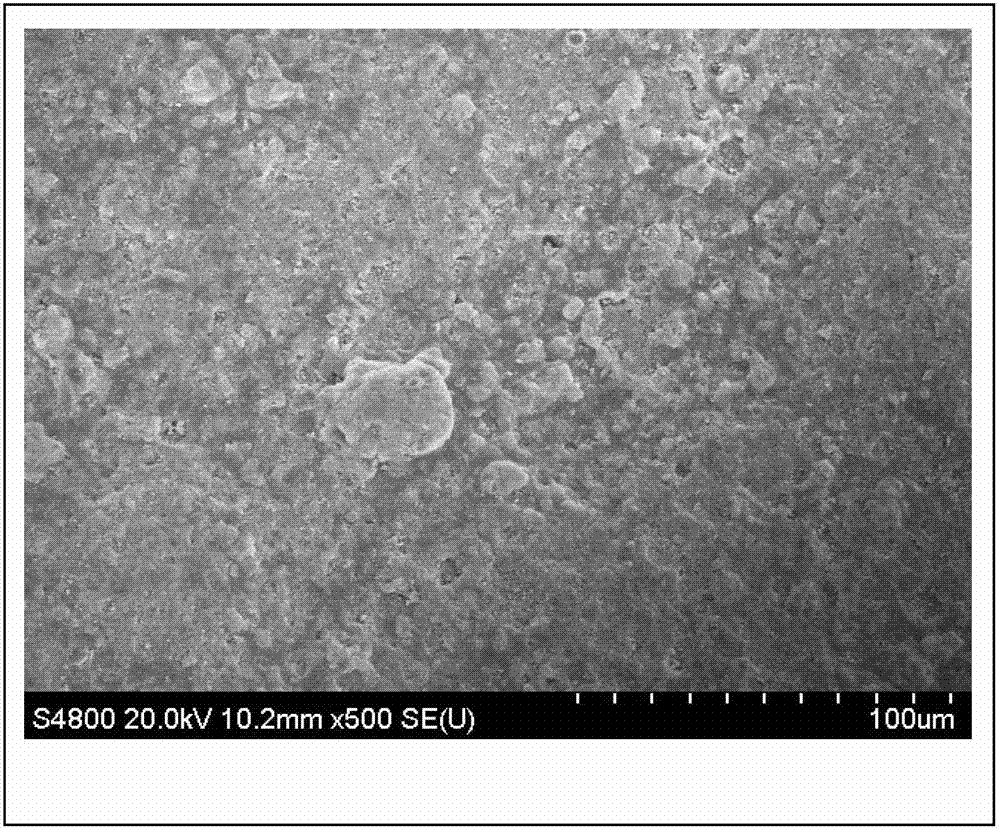

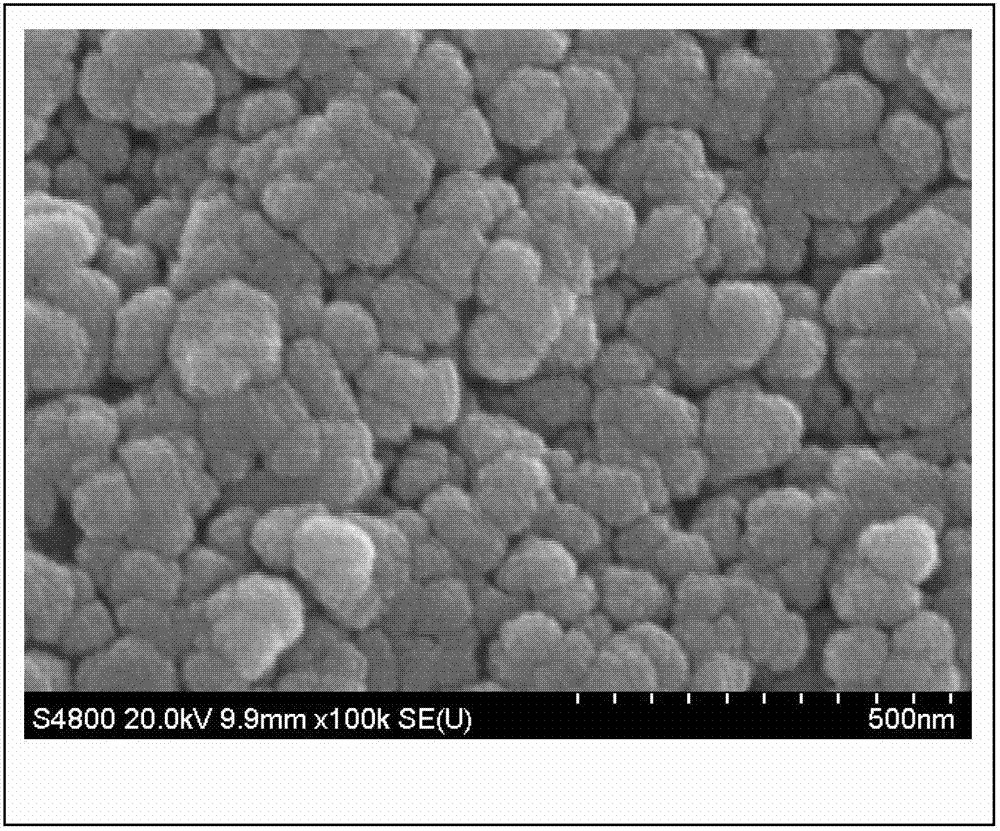

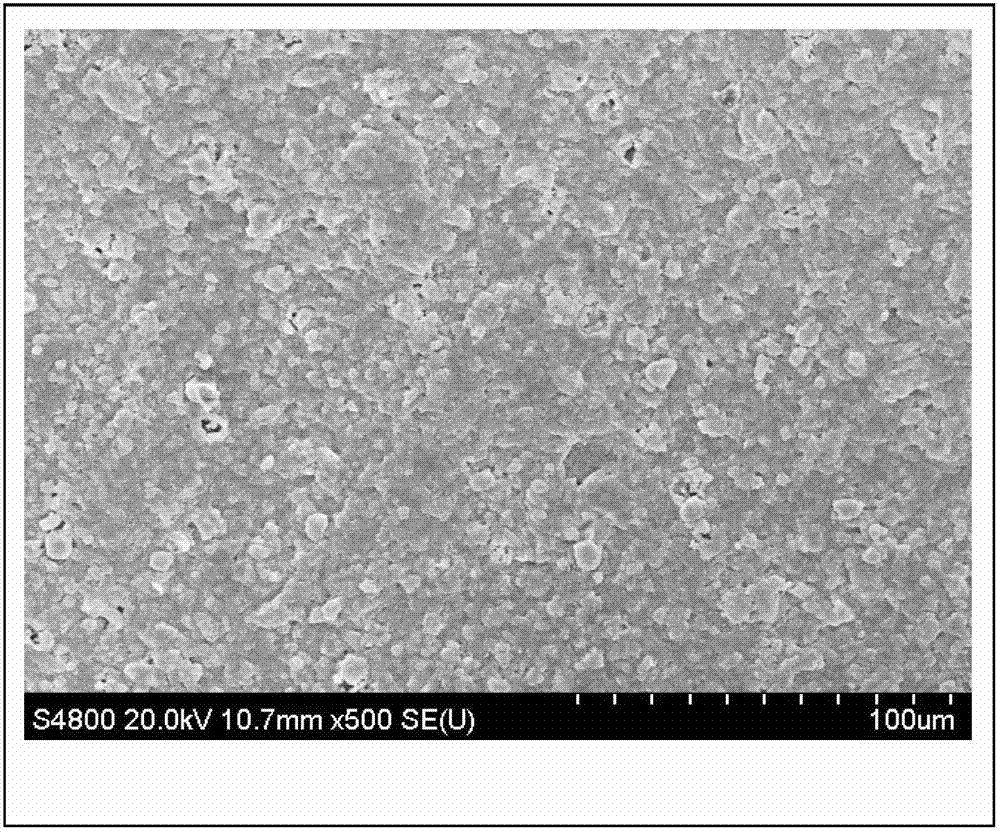

Embodiment 1

[0026] Convert titanyl sulfate to titanium dioxide equivalent, configure titanyl sulfate solution with a mass content of 2.5% titanium dioxide, stir at room temperature for 4 hours to dissolve, filter with 4 layers of medium-speed filter paper to remove solid impurities; weigh a certain mass of dispersant disper740w Add it into the titanyl sulfate solution, prepare a solution with a dispersant mass fraction of 1%, and mix evenly. Under the conditions of a reaction temperature of 25° C., a fixed rate of addition and a stirring speed, the molar ratio of the titanyl sulfate to titanyl sulfate is 1: 1.2 Add ammonium oxalate or oxalic acid solution dropwise to titanyl sulfate solution, stir and react for 1 hour, cool with ice water bath to precipitate out of the solution, filter the precipitate and use 1% oxalic acid or ammonium oxalate solution to treat the precipitate several times Recrystallization removes impurity ions to obtain titanium oxalate precipitation with less impurity ...

Embodiment 2

[0028]Convert titanyl sulfate to titanium dioxide equivalent, configure titanyl sulfate solution with a mass content of 5% titanium dioxide, stir at room temperature for 4 hours to dissolve, filter with 4 layers of medium-speed filter paper to remove solid impurities; weigh a certain mass of dispersant disper750w Add it into titanyl sulfate solution to prepare a solution with a mass fraction of 5% dispersant and mix evenly. Under the conditions of reaction temperature of 50°C, constant addition rate and stirring speed, the molar ratio of titanyl sulfate to ammonium oxalate is 1:1.5. Or add oxalic acid solution dropwise to titanyl sulfate solution, stir and react for 1 hour, cool with ice water bath to precipitate out of the solution, filter the precipitate and use 1% oxalic acid or ammonium oxalate solution to remove the precipitate by multiple recrystallization Impurity ions obtain titanium oxalate precipitation with less impurity content; convert titanium oxalate into titaniu...

Embodiment 3

[0030] Convert titanyl sulfate to titanium dioxide equivalent, configure titanyl sulfate solution with a mass content of 0.5% titanium dioxide, stir at room temperature for 4 hours to dissolve, filter with 4 layers of medium-speed filter paper to remove solid impurities; weigh a certain mass of dispersant disper752w Add to titanyl sulfate solution to prepare a solution with a mass fraction of dispersant of 0.5% and mix evenly. Under the conditions of reaction temperature of 60°C, fixed dropping speed and stirring speed, the molar ratio of titanyl sulfate to ammonium oxalate is 1:1. Or add oxalic acid solution dropwise to titanyl sulfate solution, stir and react for 1 hour, cool with ice water bath to precipitate out of the solution, filter the precipitate and use 1% oxalic acid or ammonium oxalate solution to remove the precipitate by multiple recrystallization Impurity ions obtain titanium oxalate precipitation with less impurity content; convert titanium oxalate into titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com