Positive image thermosensitive lithographic printing plate

A lithographic printing plate, printing plate technology, applied in printing, photosensitive materials for optomechanical equipment, printing plate preparation, etc., can solve the problems of low developing latitude, low plate sensitivity, and difficult plate development, etc. Achieve the effect of improving sensitivity and developing latitude, promoting development and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0081] Synthesis of Alkali-Soluble Resin R1 Resin

[0082] In a 1000ml four-neck flask, install a top stirrer, a condenser tube, and a dropping funnel, and feed nitrogen gas to eliminate oxygen in the bottle. Add 200ml of ethyl cellosolve, 200ml of DMF, 0.6g of dibenzoyl peroxide, and 20g of acrylamide. Start stirring to dissolve, add 5g of methacrylic acid, 5g of acrylonitrile, 10g of N-phenylmaleimide, stir for 10 minutes, start to heat up to 75°C, react for 1 hour, start to drop mixed monomers (15g of acrylamide, Dissolve 5g of methyl methacrylate in 50ml of ethyl cellosolve), drop it within 1 hour, continue to react for 4 hours, after the reaction, cool down to room temperature, add 0.5g of hydroquinone (dissolved in 50ml of ethyl cellosolve) cellosolve), stirred for 10 minutes, and then slowly added the reaction mixture into 4 liters of water to obtain a white solid, which was filtered, washed three times, and dried in a vacuum oven.

[0083] Prepare the resin layer of p...

Embodiment 6-11

[0108] Synthesis of Solvent Resistant Resin R2 Resin

[0109] In a 1000ml four-necked flask, install a stirring tube, a condenser, and a dropping funnel, and feed nitrogen to remove oxygen in the bottle. Add 200ml of ethyl cellosolve, 200ml of DMF, 0.6g of dibenzoyl peroxide, and 20g of acrylamide. Start stirring to dissolve, add 5g of methacrylic acid, 5g of acrylonitrile, 10g of propylene sulfonamide, stir for 10 minutes, start to heat up to 75°C, react for 1 hour, start to drop mixed monomers (acrylamide 15g, methacrylic acid 5g into 50ml ethyl cellosolve), drop it in 1 hour, and continue to react for 4 hours. minutes, and then slowly add the reaction mixture into 4 liters of water to obtain a white solid, which was filtered, washed three times, and dried in a vacuum oven.

[0110] Prepare the resin layer of the positive thermosensitive lithographic printing plate plate according to the following formula: the formula of embodiment 1-5 replaces RI with R2, IR absorbing dye ...

Embodiment 12

[0113] Prepare the resin layer of positive thermosensitive lithographic printing plates according to the following formula:

[0114] N, N-dimethylformamide (DMF) 6 parts by weight

[0115] 2 parts by weight of water

[0116] 25 parts by weight of ethyl cellosolve

[0117] Acrylic resin R1 1.5 parts by weight

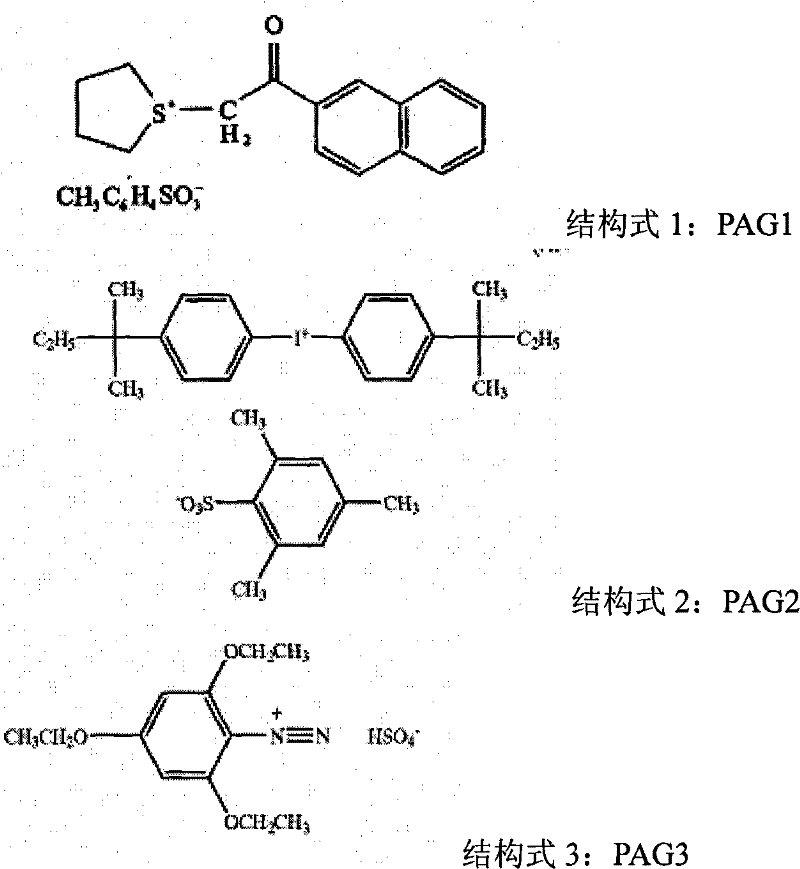

[0118] PAG 5 (Shandong Weihai Tiancheng Chemical Technology Co., Ltd.) 0.11 parts by weight

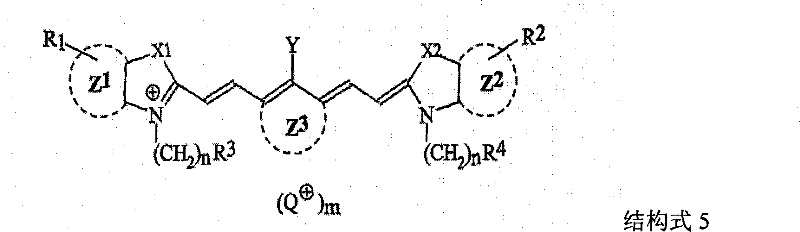

[0119] IR absorbing dye A (lambdamax = 830nm) (see structure above)

[0120] Eastman kodak, rochester, NV, USA) 0.02 parts by weight

[0121] IR absorbing dye B (lambdamax = 830nm) (see structure above)

[0122] (Eastman kodak, rochester, NV, USA) 0.02 parts by weight

[0123] BYK-307 Polyethoxylated Dimethicone Copolymer

[0124] (BYK Chemie, Wallingford, CT, USA) 0.0035 parts by weight

[0125] Crystal violet (Hodogaya Chemical CO.LTD) 0.04 parts by weight

[0126] Prepare the thermosensitive layer of positive thermosensitive lithographic printing plate plate material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com