Powder coating used for heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar, heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar, and manufacturing method and applications of heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar

A technology of powder coating and gripping force, which is applied in the direction of anti-corrosion coatings, coatings, conductive coatings, etc., can solve problems such as patent publications that have not been found, and achieve excellent anti-corrosion effects, delay metal corrosion, and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

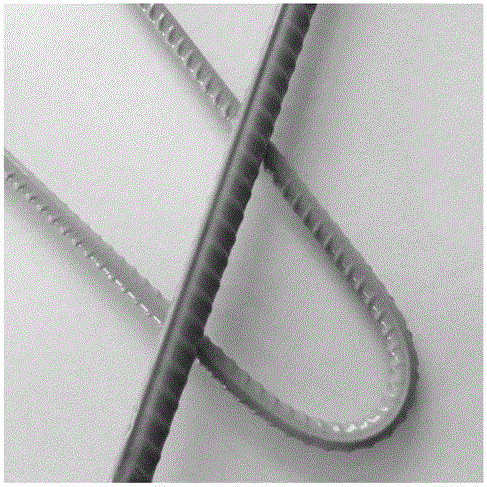

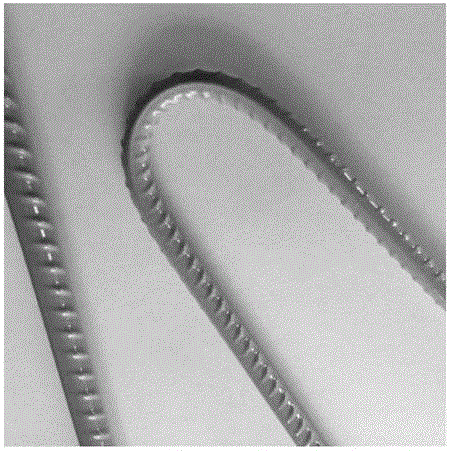

Image

Examples

Embodiment 1

[0048] A heavy-duty anti-corrosion high-holding force double-coated powder coating for thin-layer steel bars, the powder coating includes a heavy-duty anti-corrosion primer and a super-tough epoxy topcoat;

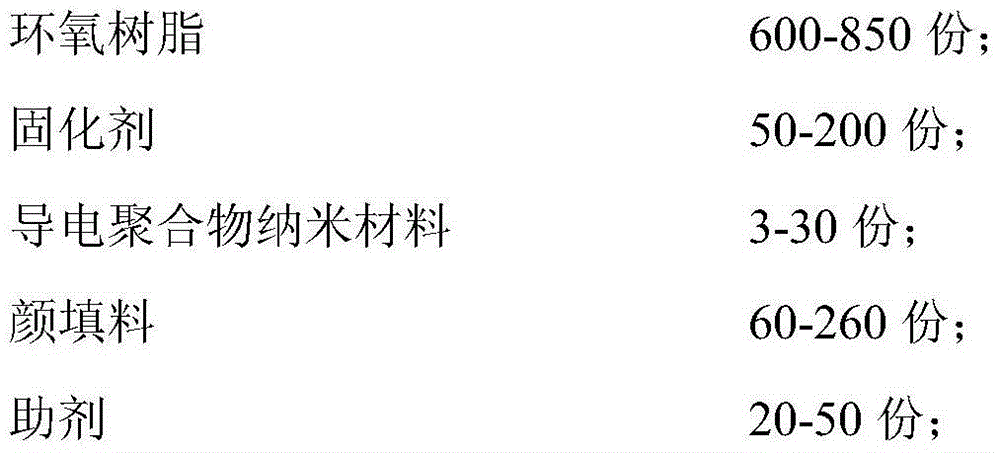

[0049] Wherein, the raw material constituents and parts by weight of the heavy-duty primer are as follows:

[0050]

[0051] The pigments and fillers are composed of inorganic pigments, rutile titanium dioxide, silicon micropowder and mica powder, and the weight ratio of inorganic pigments, rutile titanium dioxide, silicon micropowder and mica powder is 10:60:50:20.

[0052] The auxiliary agent is composed of a brightener, a leveling agent, a toughening agent and a degassing agent, and the weight ratio of the brightening agent, the leveling agent, the toughening agent and the degassing agent is 8:6:18:3;

[0053] The above-mentioned materials are added to a high-speed mixer according to parts by weight, and after dry mixing, they are added to an extruder for conventiona...

Embodiment 2

[0067] A heavy-duty anti-corrosion high-holding force double-coated powder coating for thin-layer steel bars, the powder coating includes a heavy-duty anti-corrosion primer and a super-tough epoxy topcoat;

[0068] Wherein, the raw material composition components and parts by weight of the heavy anticorrosion primer are respectively:

[0069]

[0070] The above-mentioned materials are added to a high-speed mixer according to parts by weight, and after dry mixing, they are added to an extruder for conventional melting, mixing, cooling, and tabletting, and then pulverized, classified, sieved, and packaged by a pulverizer. It becomes the finished product of heavy-duty anti-corrosion primer powder coating for steel bars;

[0071] The raw material constituents and parts by weight of the super-tough epoxy topcoat are respectively:

[0072]

[0073] Weigh bisphenol A type epoxy resin NPES-907 and carboxyl-terminated liquid nitrile rubber modified epoxy resin KR-102 in proporti...

Embodiment 3

[0077] A heavy-duty anti-corrosion high-holding force double-coated powder coating for thin-layer steel bars, the powder coating includes a heavy-duty anti-corrosion primer and a super-tough epoxy topcoat;

[0078] Wherein, the raw material composition components and parts by weight of the heavy anticorrosion primer are respectively:

[0079]

[0080] The above-mentioned materials are added to a high-speed mixer according to parts by weight, and after dry mixing, they are added to an extruder for conventional melting, mixing, cooling, and tabletting, and then pulverized, classified, sieved, and packaged by a pulverizer. It becomes the finished product of heavy-duty anti-corrosion primer powder coating for steel bars;

[0081] The raw material constituents and parts by weight of the super-tough epoxy topcoat are respectively:

[0082]

[0083] The special tough epoxy resin is made by mixing bisphenol A epoxy resin and carboxyl-terminated liquid nitrile rubber modified ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com