Double layer coating, its preparation and its use for rendering ultra water-repellent and antireflective the surfaces to which it is applied

A double-layer coating and coating technology, which is applied to devices, coatings, and special surfaces for coating liquid on the surface, can solve the problems of high cost, poor chemical stability, and inconvenience of fluorinating agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] -Si(CH 3 ) 3 Group Functionalized Microparticles

[0044] A suspension containing 5wt% silicon powder (specific surface area 150m 2 / g) (CAS No.7631-86-9), the solvent is 2-pentanone (CAS No.107-87-9), the suspension was kept stirring for 24 hours, and then mixed with hexamethyldisilazane ( CAS No.999-97-3) mixed at a volume ratio of 1:2. The mixture was then heated to 60°C and kept stirring under nitrogen atmosphere for 24 hours. The microparticles were then centrifuged, the supernatant was discarded, washed twice with diethyl ether (CAS No. 60-29-7), and the product was dried at 150°C for 5 minutes. The surfaces of the resulting particles are covered with polar end groups -Si(CH 3 ) 3 This determines its hydrophobicity.

example 2

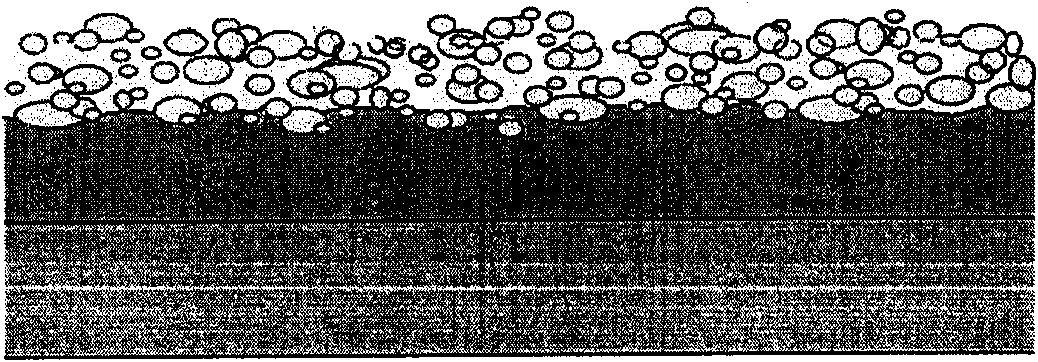

[0046] Formation of the superhydrophobic coating of the present invention

[0047] First layer of epoxy resin (CAS No. 28906-96-9) containing crosslinker triarylsulfonium hexafluorophosphate (CAS No. 89452-37-9; 71449-78-0) with a thickness of 250 nm deposited on a glass substrate. On this uncrosslinked (uncured) resin was deposited a second layer starting from a solution of 2-pentanone (CAS No. 107-87-9) containing 7.1 wt% of The epoxy resin of triaryl hexafluorosulfonium phosphate, and 4.8wt%-Si(CH) obtained by the method of Example 1 3 ) 3 Group functionalized silicon particles. The total thickness of the double layer coating is 320 nm. The substrate was then heated to 80 °C for 1 min to facilitate solvent evaporation, and exposed to UV radiation (wavelength 360 nm, dose 150 mJ / cm 2 ), and then heated to 180°C for 15 minutes. The glass surface thus treated exhibits a contact angle of 163° and a lag angle (or flow angle) of less than 3° relative to the interaction wi...

example 3

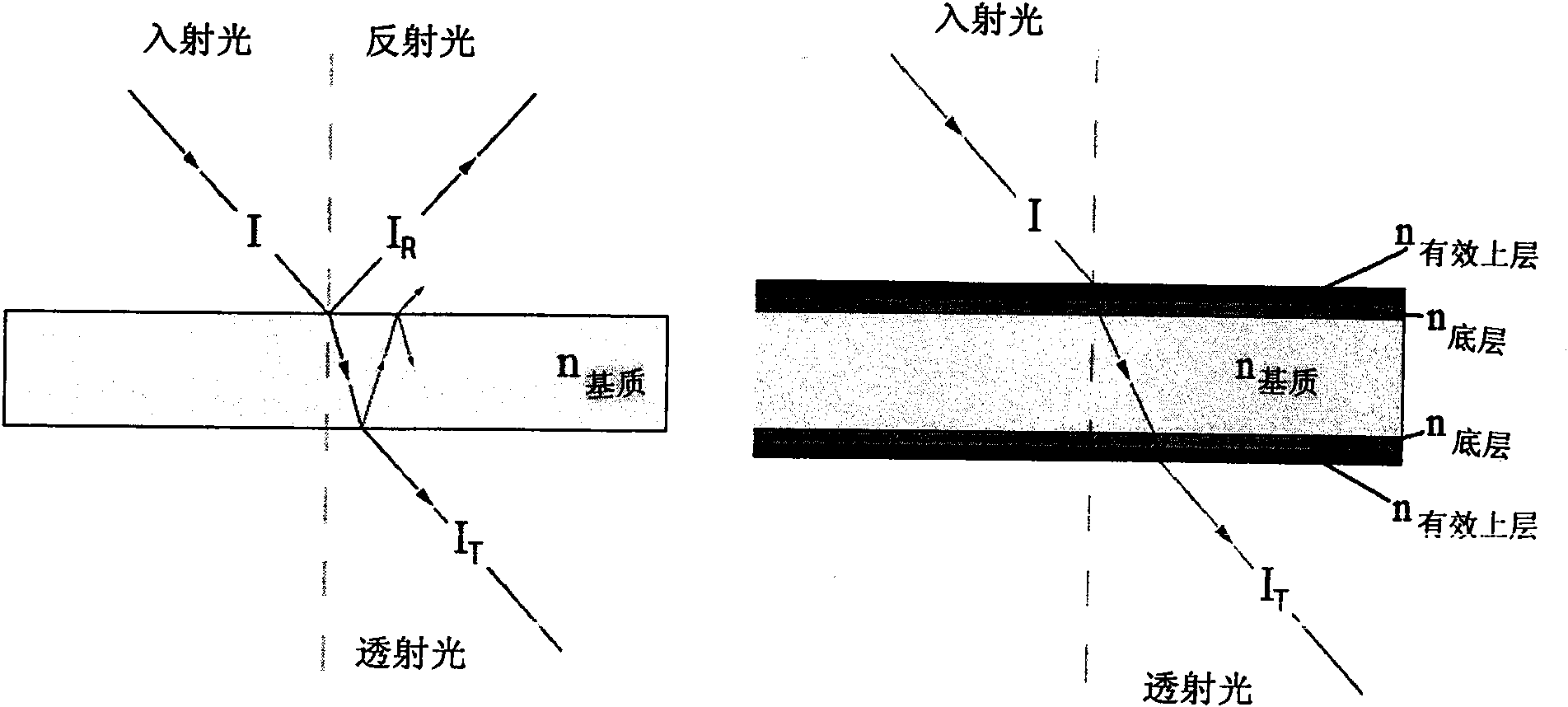

[0049] Formation of Superhydrophobic and Antireflective Coatings of the Invention

[0050] Polydimethylsiloxane (PDMS) (CAS No.9016-00-6) containing crosslinker dimethyl-hydrogenmethylsiloxane (CAS No.68037-59-2) with a thickness of 180nm A layer is deposited onto a glass substrate.

[0051] The second layer is then deposited, starting from a toluene solution (CAS No. 108-88-3) containing 3.1 wt% PDMS and 3.8 wt% -Si(CH 3 ) 3 Group functionalized silicon particles. The total thickness of the double layer coating is 270 nm. The matrix was then heated to 80°C for 12 hours.

[0052] The glass surface thus treated exhibited a contact angle of 161° and a hysteresis angle (or flow angle) of less than 3° relative to the interaction with water droplets. In addition, the glass surface thus treated exhibited a transparency of 95% across the visible light spectrum under light at an incident angle of 30°, compared to 91% for the untreated substrate. Two spectra are shown in Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com