Composite bright enhancement film

A technology of brightening film and light-concentrating layer, applied in the direction of light guide, optics, optical components, etc., can solve the problems of poor utilization of light source and high cost of backlight module, and achieve the effect of improving work quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

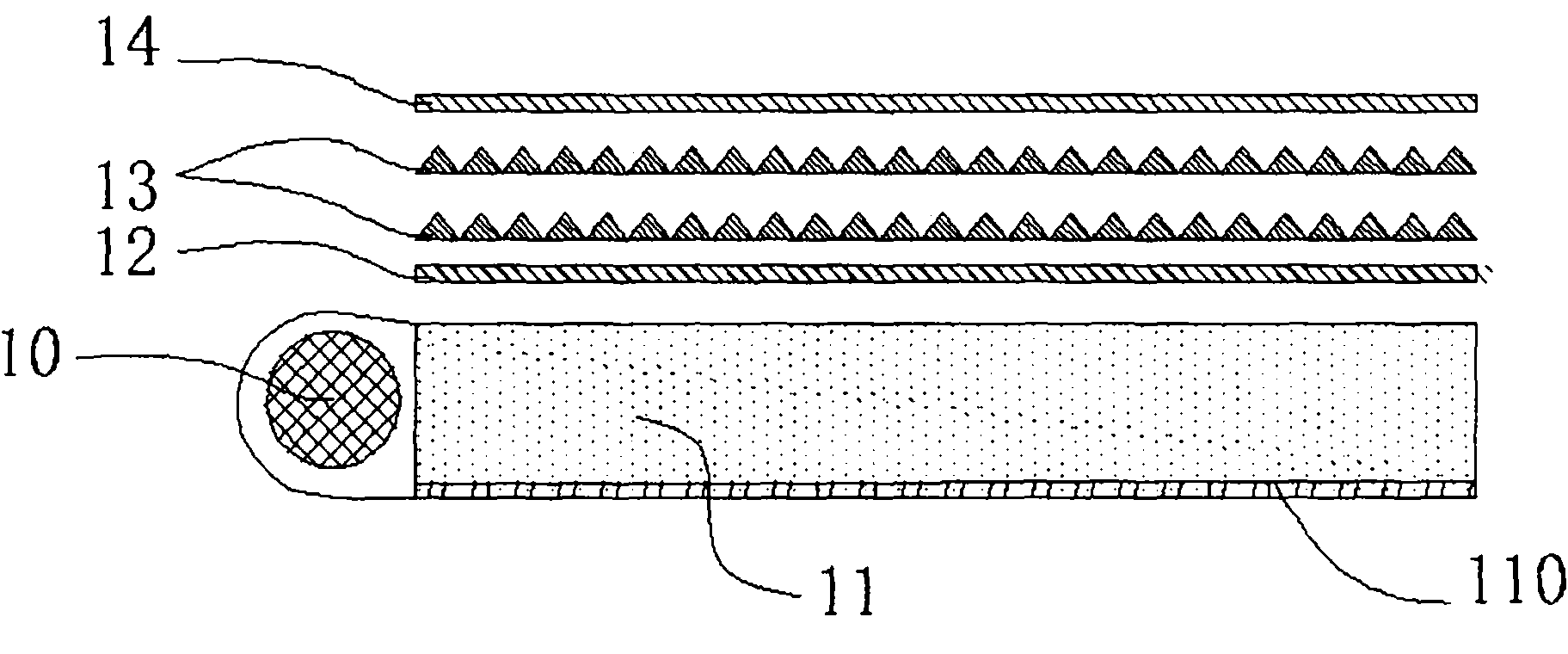

[0019] The present invention provides a composite brightness enhancement film and a backlight module. In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

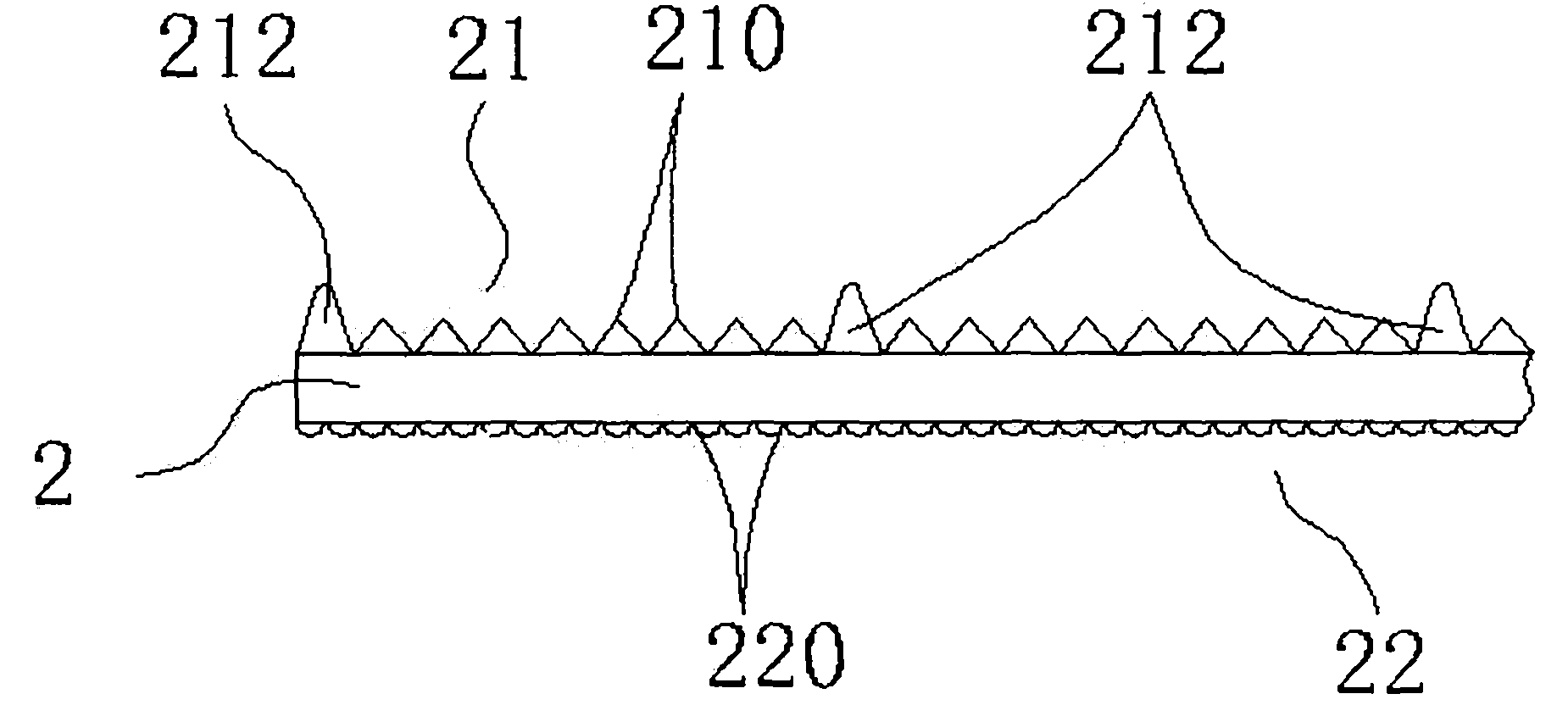

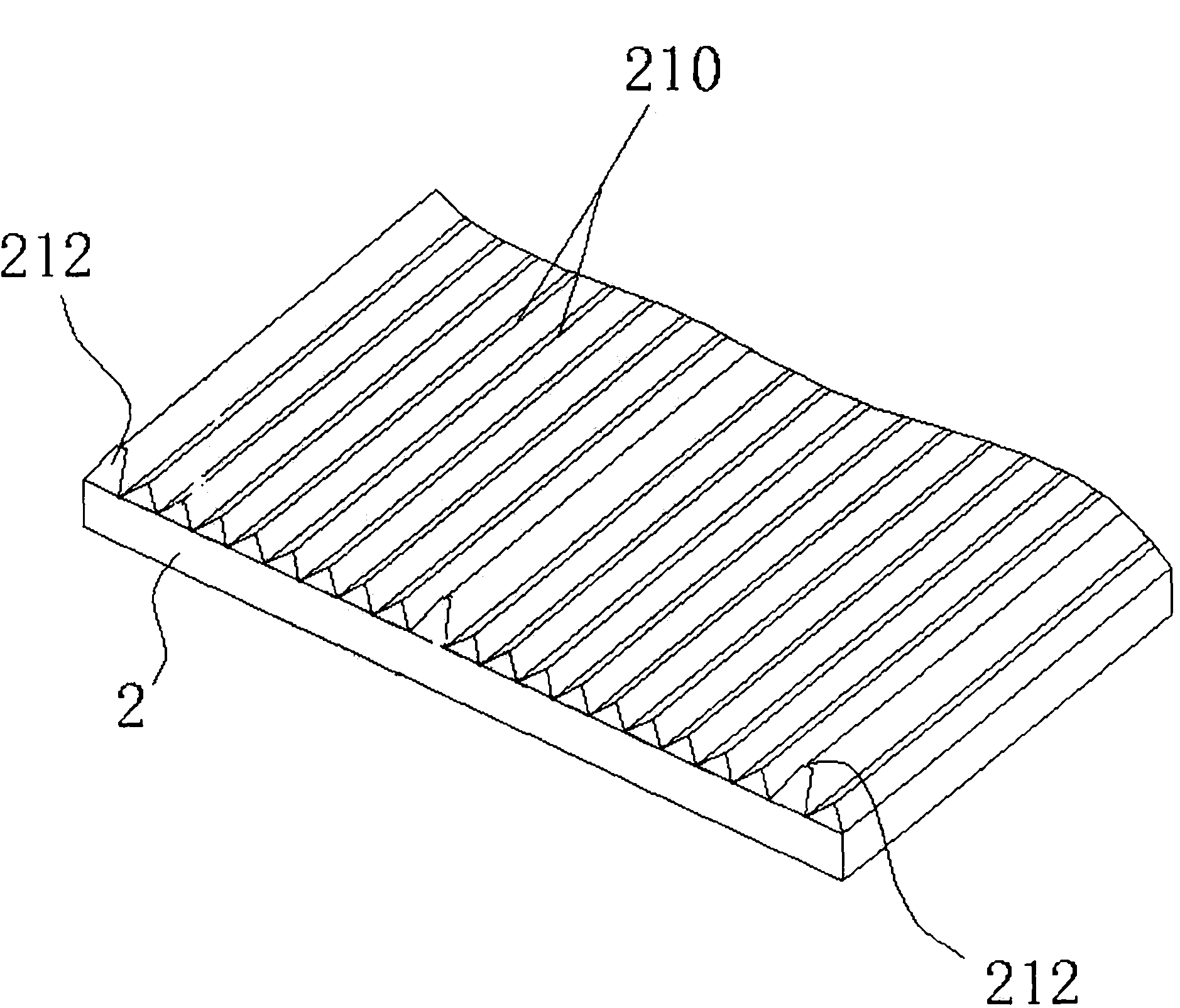

[0020] See Figure 2 to Figure 4 The composite brightness enhancement film of the present invention includes a transparent film layer 2, a light-concentrating layer 21, and an atomization layer 22. The light-concentrating layer 21 and the atomization layer 22 are integrated with the transparent film layer 2, and the light-concentrating layer 21 and the atomization layer The layers 22 are arranged relatively.

[0021] The material of the transparent film layer 2 is polyethylene terephthalic acid (PET). The thickness of the transparent film layer 2 is about 50 microns.

[0022] The light-concentrating layer 21 is a V-cut light-concentrating stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com