Large-capacity weak grating array processing apparatus and method

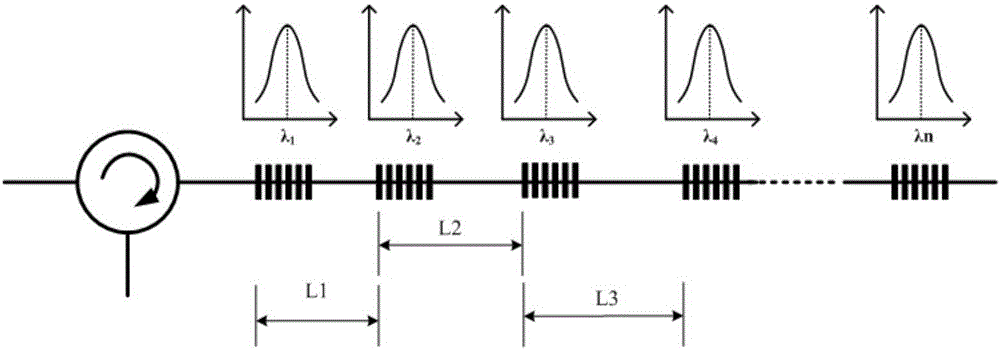

A technology for processing equipment and grating arrays, which is applied in the field of large-capacity weak grating array processing equipment, which can solve the problem that pulse width and signal-to-noise ratio are difficult to achieve high spatial resolution, multiplexing capacity is limited, spectral shadowing and crosstalk beat frequency, grating complex It can improve the sensing distance and multiplexing capacity, compensate for the spectral shadow effect, and improve the multiplexing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

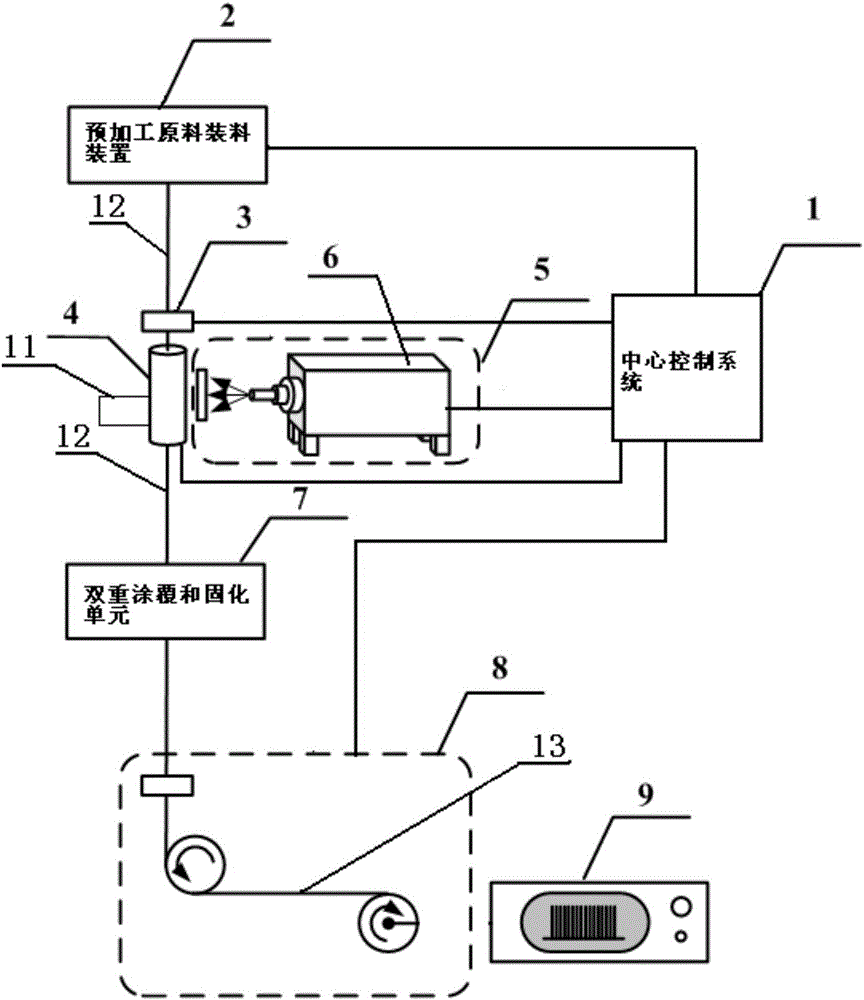

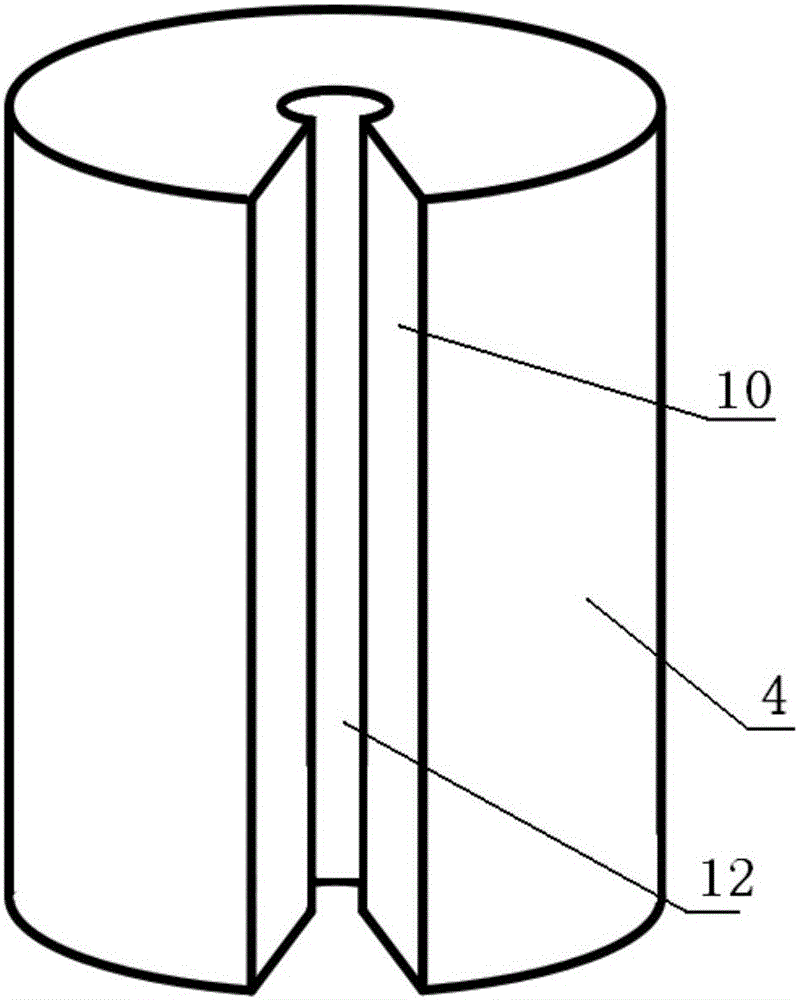

[0030] Such as figure 1 and 2 The large-capacity weak grating array processing equipment shown includes a central control system 1, a pre-processing raw material charging device 2, a bare fiber diameter monitoring device 3, an optical fiber processing temperature control device 4, an FBG writing platform 5, double coating and curing Unit 7 and FBG winding device 8, the bare fiber output end of the pre-processed raw material charging device 2 corresponds to the bare fiber input end of the bare fiber diameter monitoring device 3, and the bare fiber output end of the bare fiber diameter monitoring device 3 corresponds to the fiber processing temperature The bare fiber input end of the control device 4, the bare fiber output end of the optical fiber processing temperature control device 4 is connected to the bare fiber input end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com