Enhanced hydrophone detection device and method based on low-bending-loss chirped grating array optical fiber

A technology of chirped grating and array optical fiber, applied in the field of enhanced hydrophone detection device, can solve the problems of low back Rayleigh scattering coupling efficiency, low signal-to-noise ratio, optical signal transmission loss, etc., and achieve high sensitivity and dynamic pressure response characteristics, increase the sensing distance, and the effect of no fusion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

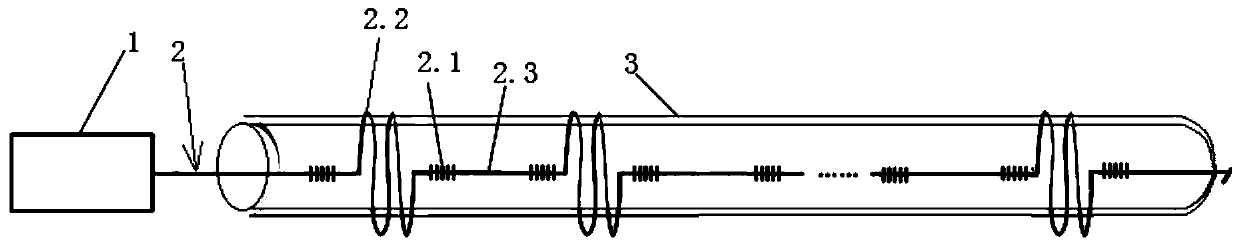

[0022] Such as figure 1 The shown enhanced hydrophone detection device based on low bending loss chirped grating array optical fiber includes interferometric distributed fiber grating acoustic sensor demodulator 1, chirped grating array optical fiber 2 and metal elastic cylinder 3. The optical fiber between two adjacent chirped gratings 2.1 in the chirped grating array fiber 2 constitutes the grating detection area, and the grating detection area includes the odd chirped grating detection area 2.2 and the even chirped grating detection area 2.3, wherein the odd chirped grating Measuring area 2.2 is used as a sensitivity-enhancing area, tightly wound on the metal elastic cylinder 3 (increasing the sensor length and density per unit area to increase the sensing sensitivity of the sensor), and the even-numbered chirped grating measuring area 2.3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com