Double-coating gel-coated sand-preventing particle and preparation method thereof

A technology of sand control particles and double coatings, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the sand control effect cannot be achieved, and achieve the effect of easy control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

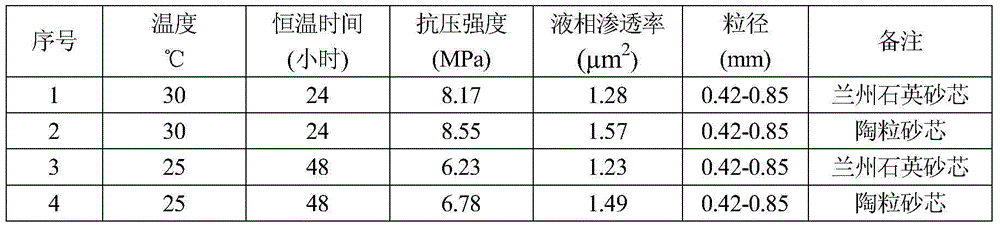

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

[0018] The double-coated rubber-encapsulated sand control particles of the present invention include A-type particles and B-type particles, the substrates of the A-type particles and B-type particles are quartz sand or ceramsite, and the particle size of the quartz sand / ceramsite is 0.4-0.8mm, or 0.6 ~ 1.1mm; one of them is used according to the process requirements during on-site operation.

[0019] Type A particles are coated with a resin coating film and an external release agent sequentially outside the quartz sand / ceramsite matrix. The resin coating film is a thin film formed by coating a resin solution on the surface of qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com