Oil-water well composite sand prevention method

A technology for oil and water wells and sand control, which is used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve problems such as inapplicability, and achieve the effects of long validity period, reduced operating costs, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: For the loose sandstone formation of cementation, earlier by directly pumping (squeezing) into the method for front fluid, utilize hydraulic impact energy, flush near wellbore zone; Carry a certain amount of film-coated sand (or other artificial sand) to make it accumulate in the cavities near the well wall; finally, the composite porogen is pumped in, and under its strengthening and consolidation effect, an artificial sand arch with high strength and high permeability is formed to achieve the purpose of sand control and production increase .

Embodiment 2

[0038] Example 2: For wells with serious reservoir pollution or dense cementation, chemical plugging removal, dissolution and mixed gas-water strong drainage, and pre-blockage removal fluid pretreatment measures are used to dredge the blockage near the wellbore and form a certain Cavities; and then use the energy of sand-carrying liquid to make the artificial sand form a high-permeability sand arch near the well wall, so as to achieve the purpose of sand control and increase production and injection.

Embodiment 3

[0039] Embodiment 3: For the very tight and sandy reservoir of cementation, first make the reservoir form artificial fractures by hydraulic fracturing; then pump the coated sand to fill between the fractures and blastholes, so that the previous radial flow becomes Straight line (the fluid first flows into the fracture, and then injects into the wellbore from the fracture); finally, under the action of the composite porogen, the sand wall consolidated in the fracture not only blocks the formation sand, but also improves the formation conductivity.

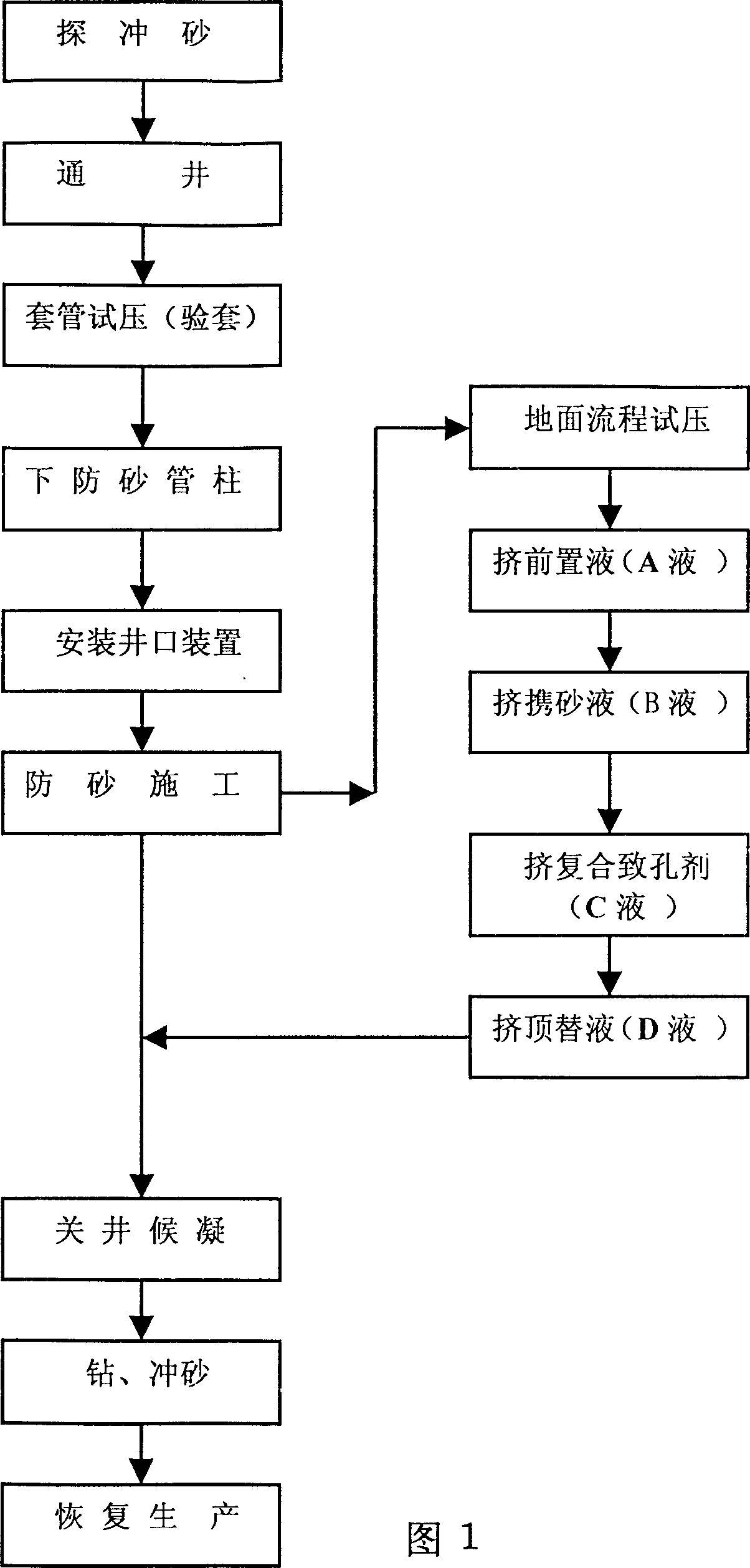

[0040] As shown in Figure 1, the construction process of the present invention is as follows in sequence: sand washing, drilling, casing pressure test, lowering sand control pipe string, installing wellhead device, sand control construction, shutting down the well and waiting for condensation, drilling sand washing, and resuming production . Among them, "sand control construction" is the core key process of the present invention, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com