Glass substrate containing silica anti-reflection film and manufacturing method of glass substrate

A silicon dioxide film, silicon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as transmittance attenuation and inability to meet industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Compared with the prior art, the preparation method of the present invention has the following advantages:

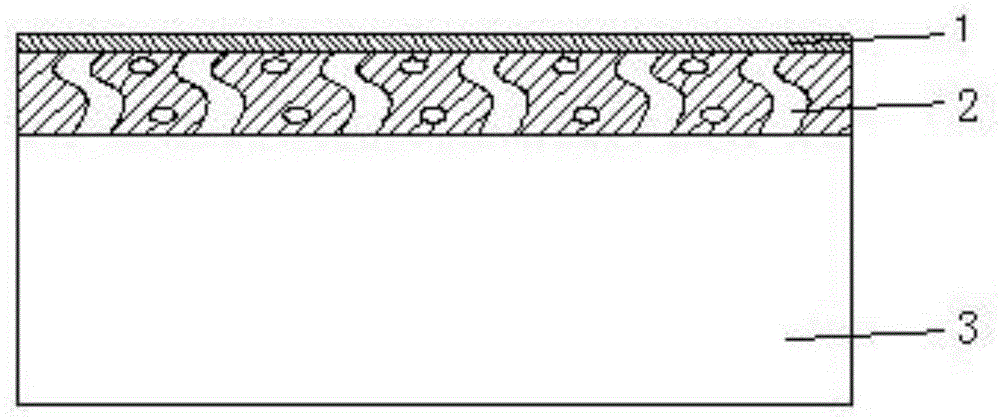

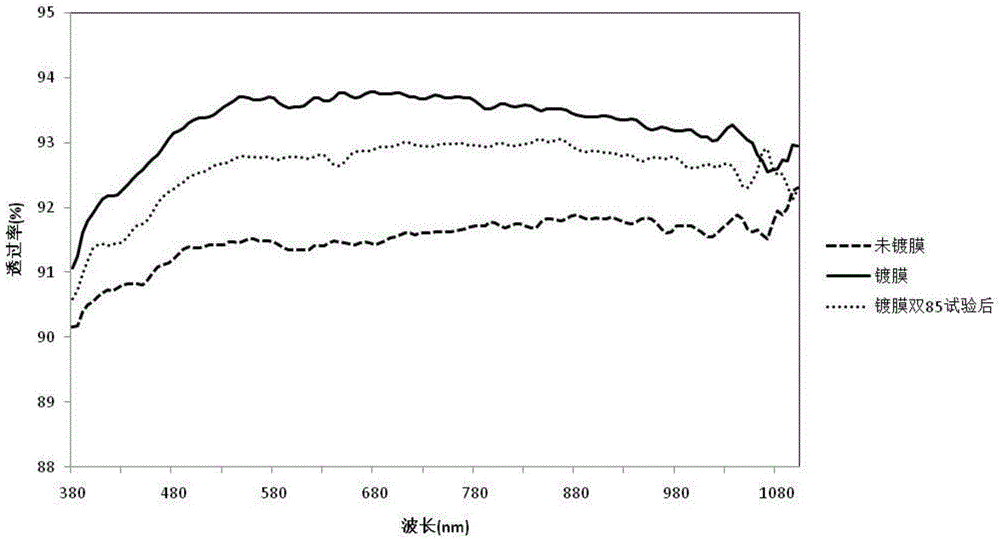

[0044] The silicon dioxide antireflection film layer with composite structure obtained by the above preparation method can easily realize the mesoporous silicon dioxide film layer and dense silicon dioxide film layer with required thickness and refractive index. The obtained silicon dioxide anti-reflection film layer can not only improve the light transmittance, but also avoid the transmittance attenuation caused by the influence of water vapor during long-term use, and can fully meet the application requirements of photovoltaic glass for solar cells. Since the coating sol is prepared after reacting under acidic conditions and / or adding suitable surfactants, the mesoporous silica film layer thus prepared has good adhesion and high hardness, and can be prepared without alkaline conditions. The problem of poor adhesion and insufficient hardness of the porous silico...

Embodiment 1

[0049] Tetraethyl silicate, ethanol, hydrochloric acid and deionized water were mixed at a molar ratio of 1:20:0.01:2, stirred for 2 hours, and then aged at room temperature for 24 hours to obtain a prepolymer sol. Take out part of the prepolymer sol and add 2.3% cationic surfactant CTAB according to the mass ratio, and continue to stir until CTAB is completely dissolved to prepare the coating film sol.

[0050] Use a roller coater to apply the coating sol on the surface of the photovoltaic glass substrate cleaned with deionized water. The roller coater uses a 60-mesh anilox roller, the speed of the coating roller is 7.0m / min, and the conveying speed is 6.8m / min; the glass after coating Curing at 120°C for 3 minutes; then spray the second film with prepolymer sol, the nozzle is 220mm from the glass, and the nozzle pressure is 0.4MPa; after coating, cure at 120°C for 3 minutes; then send it to the tempering furnace and heat at 650°C 150 seconds. The diameter of the mesopores p...

Embodiment 2

[0052] Tetraethyl silicate, isopropanol, hydrochloric acid and deionized water were mixed at a molar ratio of 1:25:0.02:5, stirred for 2 hours, and aged at room temperature for 24 hours to obtain a prepolymer sol. Take out part of the prepolymer sol and add 2% tri-block copolymer P123 according to the mass ratio, and continue to stir until the P123 is completely dissolved to prepare the coating film sol.

[0053] Use a roller coater to apply the coating sol on the surface of the photovoltaic glass substrate cleaned with deionized water. The roller coater uses a 60-mesh anilox roller, the speed of the coating roller is 7.0m / min, and the conveying speed is 6.8m / min; the glass after coating Curing at 120°C for 3 minutes; then spray the second layer of film with prepolymer sol, the nozzle is 220mm from the glass, and the nozzle pressure is 0.4MPa; after coating, cure at 120°C for 3 minutes; then send it to the tempering furnace and heat at 640°C 160 seconds. The diameter of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com