Exterior coating antifogging film and preparation method

An anti-fog film and coating technology, applied in the direction of coating, etc., can solve problems such as easy to cause disease, rot, and affect the light transmittance of agricultural shed film, and achieve the effect of simple coating method and simple curing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

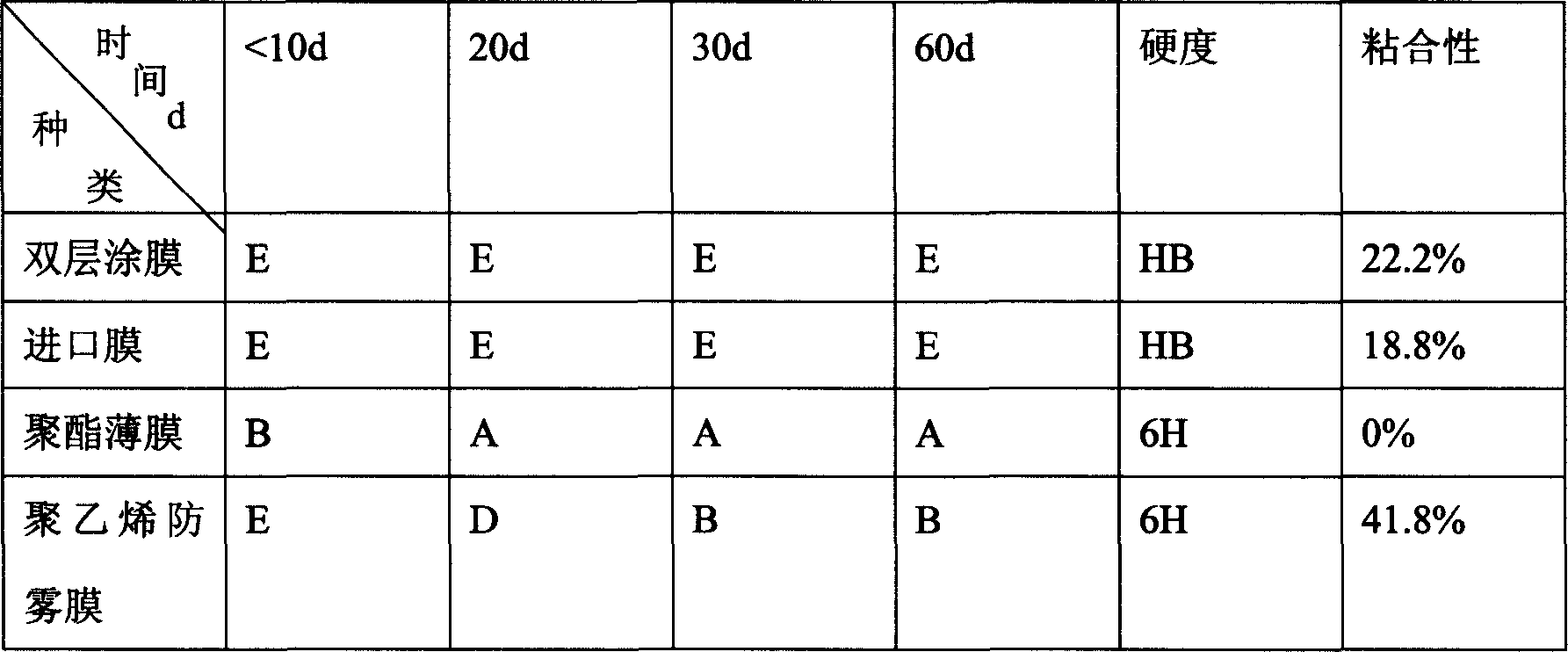

Image

Examples

Embodiment

[0038] Recipe 1 (Coat 1):

[0039] γ-(Methylpropyloxy)propyltrimethoxysilane (KH-70), 5.0g, was hydrolyzed with a small amount of hydrochloric acid, and 2.0g of acetic acid was added at the same time to adjust the pH to about 2.0. While stirring, add 6.5 grams of hydrolyzed tetraethyl orthosilicate and butyl titanate, add 0.1 grams of benzophenone (dissolved with a small amount of ethanol), and let it stand. The coating is dried at 60°C for 0.5 hours, then at a wavelength of 270-420nm, with a light intensity of 35mw / cm 2 Irradiated under a UV mercury lamp for 2 min.

[0041] γ-(2,3-Glycidoxy)propyltrimethoxysilane (KH-60), 3.0 grams, hydrolyzed with a small amount of hydrochloric acid, and at the same time, 2.0 grams of malonic acid was added to adjust the pH to about 3.5. While stirring, add 7.5 grams of hydrolyzate of ethyl orthosilicate and 5.0 grams of hydrolyzate of butyl titanate, stir and disperse at high speed with a high-speed dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com