Rope coating finishing device and coating method thereof

A coating finishing and rope technology, which is applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., can solve the problems of poor coating uniformity, low production efficiency, waste of raw materials, etc., and achieve waste reduction and simple structure , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Preparation of coating finishing solution: use polyethylene to prepare coating finishing solution with a solid content of 10%;

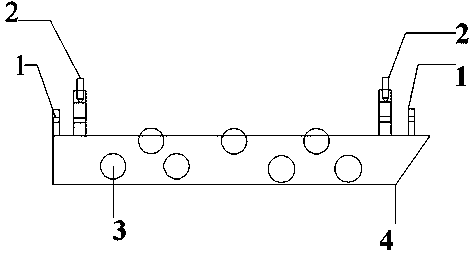

[0036] 2) Filling the coating finishing solution: fill the prepared coating finishing solution into the box body 4, and ensure that 1 / 2 of the sheave 3 in the lower row is immersed in the finishing solution;

[0037] 3) Coating finishing: the rope to be sorted is passed through the grinding port 1 and the rolling wheel into the coating finishing liquid in sequence, through a series of sheaves 3, and then through the rolling wheel 2 and the grinding port 1 at the other end of the box body 4, Enter the oven, adjust the direct pressure of the two rollers on the rope through the adjustment pin on the top of the roller 2, and adjust the thickness of the coating;

[0038] 4) Baking: The baking temperature of the rope in the oven is 150°C, and the baking time is 5s;

[0039] 5) Estimate the coating thickness: measure the quality of the baked rope...

Embodiment 2

[0041] 1) Preparation of coating finishing liquid: use polyurethane to prepare coating finishing liquid with a solid content of 30%;

[0042] 2) Filling the coating finishing solution: fill the prepared coating finishing solution into the box body 4, and ensure that 2 / 3 of the sheaves 3 in the lower row are immersed in the finishing solution;

[0043] 3) Coating finishing: the rope to be sorted is passed through the grinding port 1 and the rolling wheel into the coating finishing liquid in sequence, through a series of sheaves 3, and then through the rolling wheel 2 and the grinding port 1 at the other end of the box body 4, Enter the oven, adjust the direct pressure of the two rollers on the rope through the adjustment pin on the top of the roller 2, and adjust the thickness of the coating;

[0044] 4) Baking: The baking temperature of the rope in the oven is 50°C, and the baking time is 120s;

[0045] 5) Estimate the coating thickness: measure the quality of the baked rope,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com