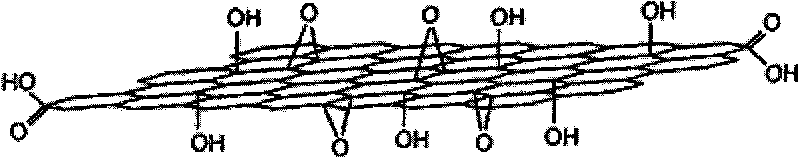

Graphene/Ru nano-composite material for supercapacitor and preparation method thereof

A technology of nanocomposite materials and supercapacitors, applied in the field of nanocomposite materials and their preparation, can solve the problems of reducing electrochemical capacitance value, reducing effective utilization of surface area, etc., and achieves the effects of improving utilization rate, high specific capacitance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Disperse 310 mg of graphite oxide nanosheets in 400 mL of glycerol by ultrasonic treatment, then add 6 mL of 0.05 M ruthenium chloride solution and 1.0 mL of 1.5 mol / L sodium acetate solution, and stir and mix well. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, heated by microwave radiation for 8 minutes, cooled, filtered, fully washed with acetone and deionized water, and dried at 90°C to obtain a graphene / Ru nanocomposite material. The ruthenium nanoparticles in the graphene / Ru nanocomposite material observed by transmission electron microscopy have a uniform particle size, with an average particle size of 2.8 nanometers. EDX analysis shows that the mass fraction of Ru in the composite is 9.8%, which is close to its theoretical value of 10%.

[0016] As a comparison, XC-72 nano-carbon was used as the nano-carbon component of the composite material, and XC-72 / Ru nano-composite material (Ru mass fraction was 10%) was prepared by th...

Embodiment 2

[0019] Disperse 230 mg of graphite oxide nanosheets in 150 mL of ethylene glycol by ultrasonic treatment, then add 10 mL of 0.05 M ruthenium chloride solution and 1.6 mL of 1 mol / L sodium acetate solution, and stir and mix well. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, heated by microwave radiation for 10 minutes, cooled, filtered, fully washed with acetone and deionized water, and dried at 90°C to obtain a graphene / Ru nanocomposite material. The ruthenium nanoparticles in the graphene / Ru nanocomposite material observed by transmission electron microscopy have a uniform particle size, with an average particle size of 3.0 nanometers. EDX analysis shows that the mass fraction of Ru in the composite is 19.5%, which is close to its theoretical value of 20%. .

[0020] As a comparison, using carbon nanotubes as the nanocarbon component of the composite material, a carbon nanotube / Ru nanocomposite material (the mass fraction of Ru is 20%)...

Embodiment 3

[0023] Disperse 230 mg of graphite oxide nanosheets in 300 mL of glycerol by ultrasonic treatment, then add 20 mL of 0.05 M ruthenium chloride solution and 2.5 mL of 1 mol / L sodium acetate solution, and stir and mix well. The homogeneous mixture was transferred to a microwave hydrothermal reaction kettle, heated by microwave radiation for 5 minutes, cooled, filtered, fully washed with acetone and deionized water, and dried at 90°C to obtain a graphene / Ru nanocomposite material. The ruthenium nanoparticles in the graphene / Ru nanocomposite material observed by transmission electron microscopy have a uniform particle size, with an average particle size of 3.2 nanometers. EDX analysis shows that the mass fraction of Ru in the composite is 32.1%, which is close to its theoretical value of 33%. .

[0024] The specific capacitance of the composite material was measured by the method of Example 1, and the measured result was: the specific capacitance of the graphene / Ru nanocomposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com