PtRu/C catalyst and its preparation method

A catalyst, ruthenium chloride technology, applied in the field of PtRu/C catalyst and its preparation, can solve the problems of PtRu/C catalyst poor dispersion, poor catalytic performance, harsh reaction conditions, etc., to achieve easy large-scale production, simple method, The effect of improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention at first provides a kind of preparation method of PtRu / C catalyst, comprises as follows:

[0026] Step 1: Dispersing the carbon carrier in water to obtain the first suspension;

[0027] Step 2: adding chloroplatinic acid solution and ruthenium chloride solution to the first suspension to obtain the second suspension;

[0028] Step 3: Pour the second suspension into the sodium borohydride solution, and stir at room temperature to obtain the PtRu / C catalyst.

[0029] According to the present invention, firstly, the carbon carrier is dispersed in water to obtain the first suspension; the present invention has no special limitation on the dispersion method, and the method of super-generation dispersion is preferably adopted, and the time of the super-generation dispersion is preferably 1h to 3h, more preferably It is 1.5h to 2.5h, and the carbon carrier can be a carbon carrier well-known to those skilled in the art without special limitation, preferab...

Embodiment 1

[0039] Add 20 mg of activated carbon produced by U.S. Cabot (Cabot) Co., trade name VulcanXC-72 to 40 mL of deionized liquid, and disperse for 2 h in super-life to obtain the first suspension; add 0.03 mmol of chlorine to the first suspension. Platinic acid solution and 0.03mmol ruthenium chloride solution were stirred for 6h to obtain a second suspension; the second suspension was poured into a newly prepared 8mL sodium borohydride solution with a concentration of 5.68mg / mL, and stirred for 12h Finally, the third suspension was obtained; the third suspension was suction-filtered and washed with deionized water with a resistivity of 18.2 MΩ·cm until no chloride ions existed, and the obtained product was vacuum-dried at 80°C.

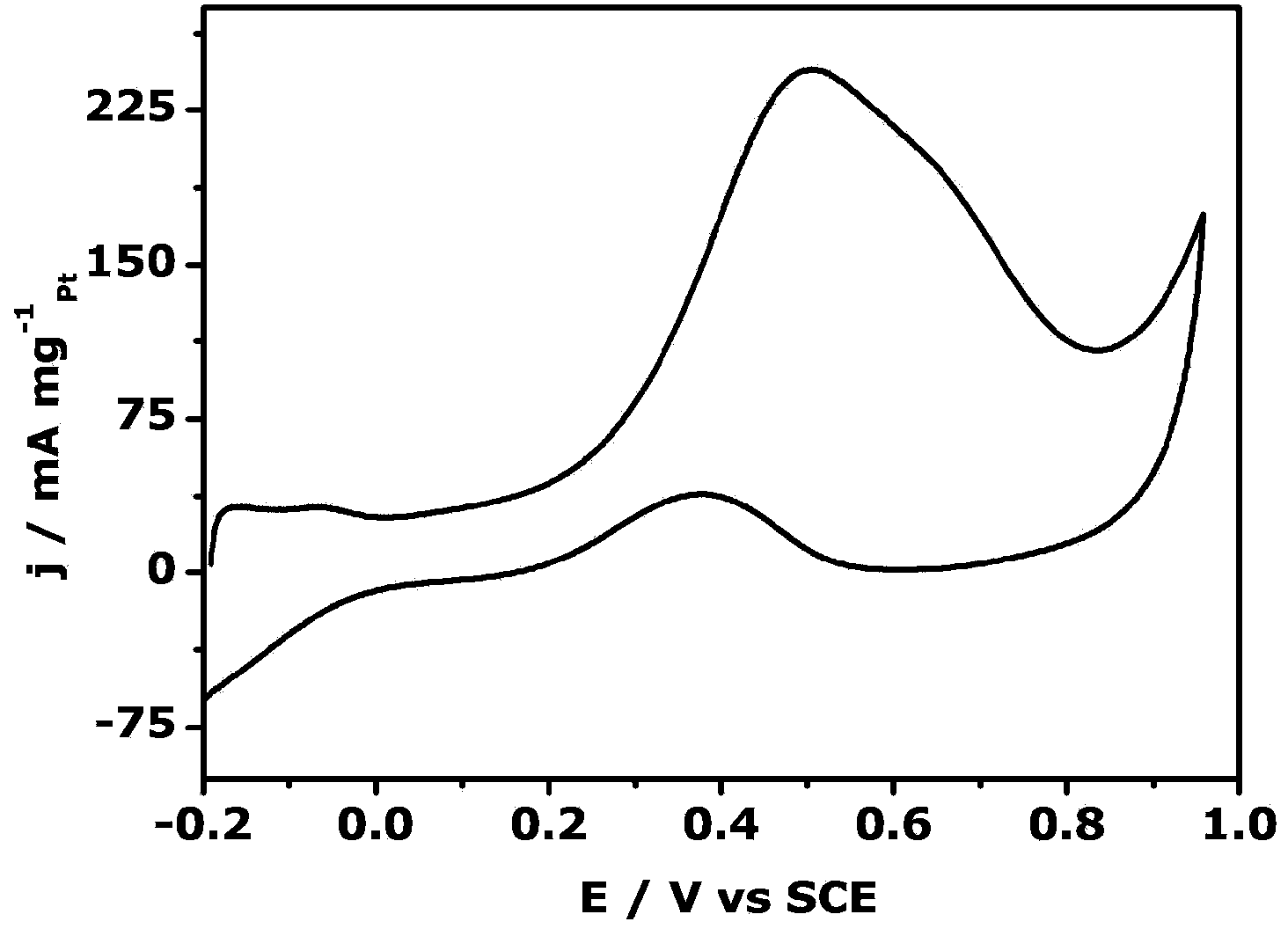

[0040] The PtRu / C catalyst is ultrasonically dispersed in ethanol to obtain a suspension; the suspension is coated on a copper grid and dried with an electron microscope, and the results can be found in image 3, image 3 For the transmission electron m...

Embodiment 2

[0043] Add 18 mg of activated carbon produced by U.S. Cabot (Cabot) Company and trade name VulcanXC-72 to 40 mL of deionization, and ultrasonically disperse for 2 hours to obtain the first suspension; add 0.03 mmol of chlorine to the first suspension. Platinic acid solution and 0.01mmol ruthenium chloride solution were stirred for 10 hours to obtain a second suspension; the second suspension was poured into newly prepared 8 mL of sodium borohydride solution with a concentration of 1.89 mg / mL, and stirred for 12 hours After that, the third suspension was obtained; the third suspension was suction-filtered and washed with deionized water with a resistivity of 18.2MΩ·cm until no chloride ions existed, and the resulting product was vacuum-dried at 80°C to obtain PtRu / C catalyst.

[0044] The PtRu / C catalyst is ultrasonically dispersed in ethanol to obtain a suspension; the suspension is coated on a copper grid and dried with an electron microscope, and the results can be found in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com