Active carbon supported ruthenium-based ammonia synthetic catalyst and preparation thereof

A technology of catalyst and activated carbon, which is applied in the field of ruthenium-based ammonia synthesis catalyst and its preparation, and achieves the effects of simple equipment, strong catalytic activity and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] Adopt the preparation step of citrate ruthenium chloride mixed impregnation method to be:

[0013] 1) Mix and dissolve ruthenium chloride citrate in water, the mass ratio of citric acid and ruthenium chloride in the mixed solution is 1:0.5~15, and the mass fraction of citric acid in the mixed solution is 1%~30% , the mass fraction of ruthenium is 1.5%~2.5%, the equal volume of mixed solution is impregnated with activated carbon; Taking the weight of activated carbon carrier as a benchmark, the content of ruthenium in the catalyst is 3.5~8% of the weight of activated carbon carrier;

[0014] 2) heat-treating the impregnated activated carbon, the heat-treatment temperature being 100-250°C;

[0015] 3) Reduction: Reducing the heat-treated activated carbon, using hydrogen-nitrogen mixed gas as the reducing gas, wherein the hydrogen is the reducing medium, the reduction temperature is 450°C, and the reduction time is 6 hours;

[0016] 4) Auxiliary loading: impregnating the ...

Embodiment 1

[0035]Get 0.22g ruthenium trichloride and 0.08g citric acid to mix and be dissolved in water (based on gac carrier weight, ruthenium and citric acid content are 4% of gac carrier weight), after citric acid and ruthenium chloride equal volume impregnation gac Dry the activated carbon under an infrared lamp, and then reduce it with a mixed gas with a volume ratio of hydrogen and nitrogen of 3:1 at 450 ° C. The reduced activated carbon is first loaded with the auxiliary agent Ba in equal volume, and then loaded with K, barium and potassium in equal volume. The weight content is respectively 4% and 12% of the weight of activated carbon carrier, and the precursors of barium and potassium are barium nitrate and potassium hydroxide respectively. The mass fraction of barium in the barium-containing solution is 0.5%-4%, and the mass fraction of potassium in the potassium-containing solution is 1%-8%.

[0036] Above also can be dissolved in water respectively with 0.22g ruthenium trichl...

Embodiment 2

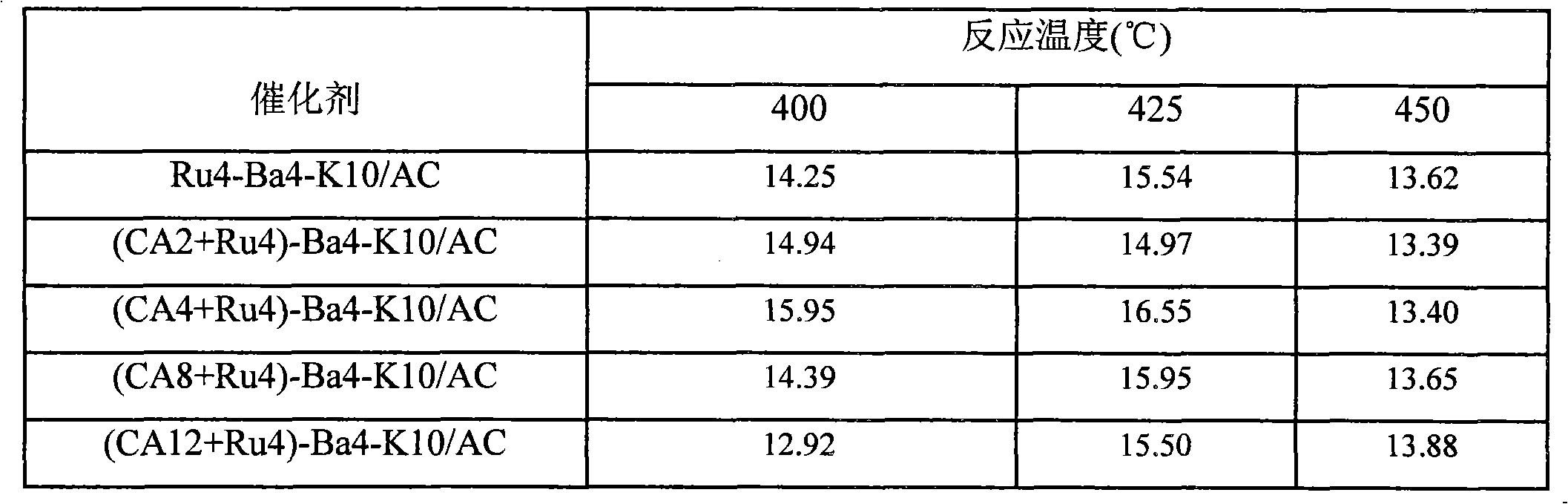

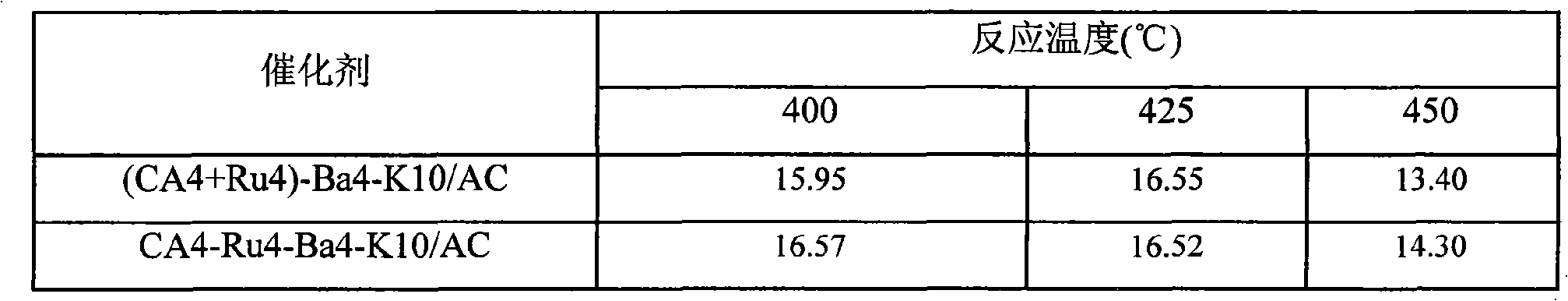

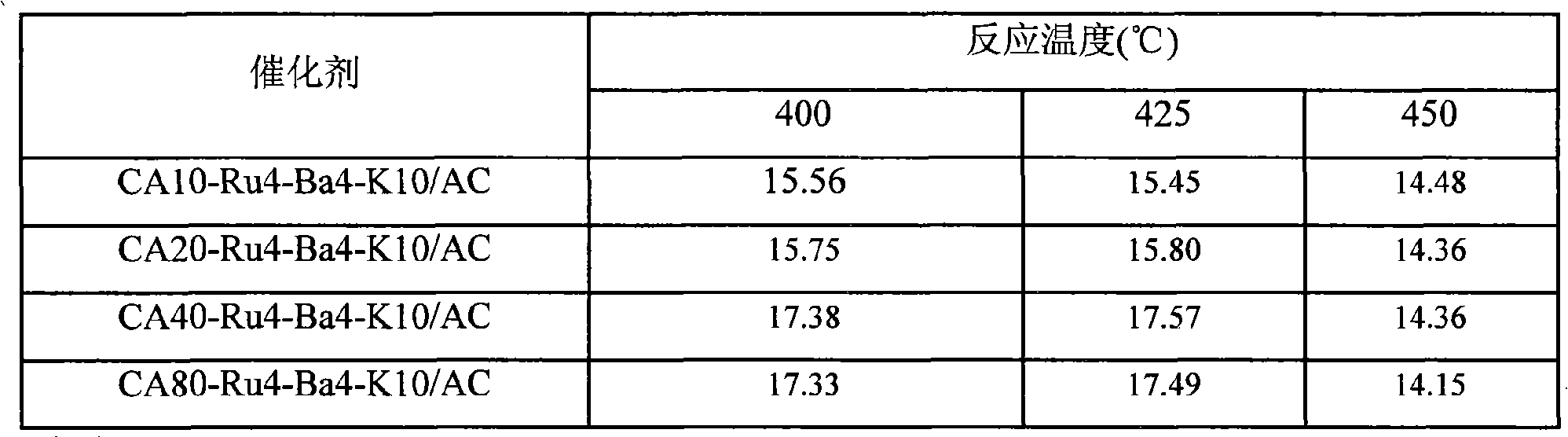

[0039] Catalyst activity evaluation was carried out in a high-pressure activity testing device. The reactor is a fixed bed with an inner diameter of 14mm. The catalyst particles are 12-16 meshes, the bulk volume is 2ml, and the catalyst is packed in the isothermal zone of the reactor. The reaction gas is a mixture of nitrogen and hydrogen, and the ratio of hydrogen to nitrogen is 3:1. Catalyst activity is expressed by the volume percentage of ammonia in the reactor outlet gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com