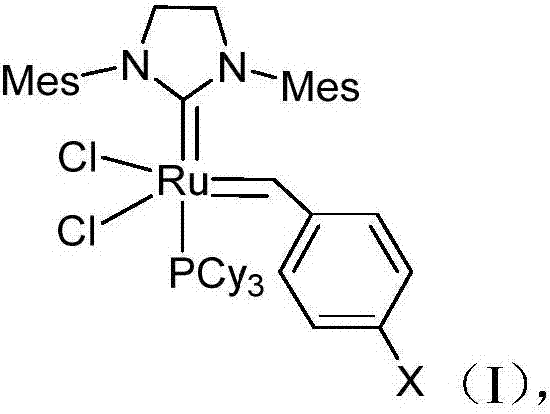

Ruthenium carbene complex, preparation method and application thereof

A carbene complex and the technology of the complex, which are applied in the field of ruthenium carbene complex and its preparation, can solve the problems of general yield of the ruthenium carbene complex and the like, and achieve the effects of stable process, convenient preparation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

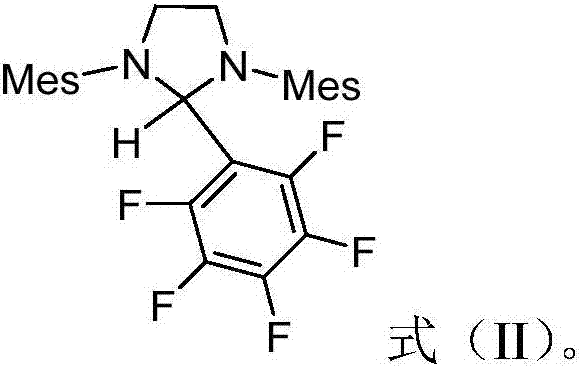

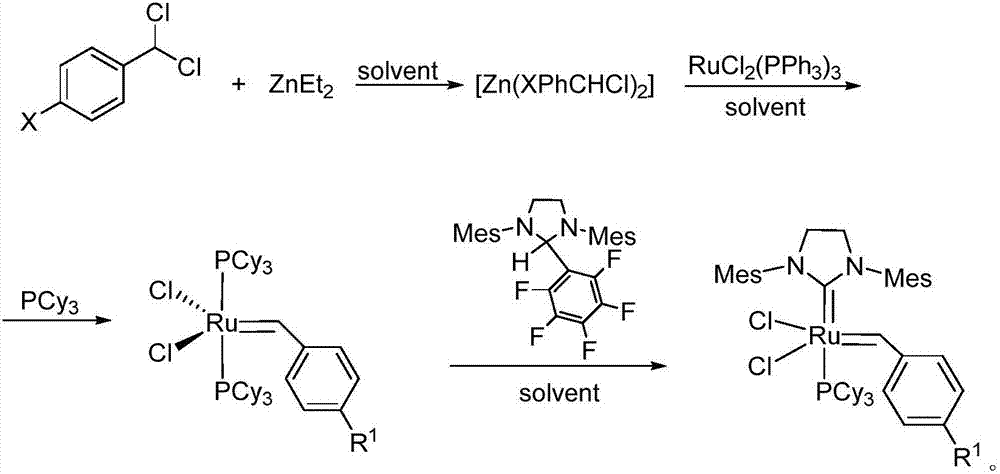

Method used

Image

Examples

Embodiment 1

[0035]Under nitrogen protection, add 500mL of dichloromethane and 50g of p-trifluoromethyldichloromethylbenzene into a 2L round bottom bottle, cool the mixture to -50°C, then slowly add 200mL of 1mol / L diethylzinc n-hexane solution. After dropping, keep stirring and reacting at this temperature for 0.5 hour, a large amount of brownish-yellow precipitate appears in the reaction flask, which is p-trifluoromethyldichloromethylbenzenediethylzinc complex. Weigh 150 g of triphenylphosphine ruthenium dichloride, dissolve it in 150 mL of dichloromethane, add it to the reaction device, and stir and react at -30°C for 2 hours. Weigh 115 g of tricyclohexylphosphine, dissolve it in 100 mL of dichloromethane, add it to the reaction flask, stir and react for 1 hour, and obtain a purple-red solution. Most of the solvent and volatile substances were removed by distillation under reduced pressure, and the residue was recrystallized at room temperature for 2 hours by adding 300mL of methanol t...

Embodiment 2

[0040] Under nitrogen protection, add 600mL tetrahydrofuran and 45g p-nitrodichloromethylbenzene into a 2L round bottom bottle, cool the mixture to -40°C, then slowly add 200mL, 1mol / L dimethyl zinc n-hexane solution dropwise . After dropping, keep stirring and reacting at this temperature for 1 hour, and a large amount of brown precipitates appear in the reaction bottle, which is p-nitrodichloromethylbenzenedimethylzinc complex. Weigh 146 g of triphenylphosphine ruthenium dichloride, dissolve it in 200 mL of tetrahydrofuran, add it to the reaction, and stir the reaction at -30°C for 2 hours. Weigh 115 g of tricyclohexylphosphine, dissolve it in 100 mL of tetrahydrofuran, add it to the reaction flask, stir and react for 1 hour to obtain a purple-red solution. Most of the solvent and volatile substances were removed by distillation under reduced pressure, and the residue was recrystallized by adding 500mL methanol at room temperature for 1 hour to obtain a large amount of brow...

Embodiment 3

[0045] Under argon protection, add 400mL of dioxane and 55g of p-cyanodichloromethylbenzene into a 2L round bottom bottle, cool the mixture to -30°C, then slowly add 200mL of 1mol / L dimethyl zinc n-hexane solution. After dropping, keep stirring and reacting at this temperature for 2 hours, and a large amount of brownish-yellow precipitates appear in the reaction flask, which is p-cyanodichloromethylxylylene dimethyl zinc complex. Weigh 146 g of triphenylphosphine ruthenium dichloride, dissolve it in 180 mL of dioxane, add it to the reaction, and stir the reaction at -20°C for 2 hours. Weigh 136 g of tricyclohexylphosphine, dissolve it with 160 mL of dioxane, add it into the reaction flask, stir and react for 1 hour, and obtain a purple-red solution. Most of the solvent and volatile substances were removed by distillation under reduced pressure, and the residue was recrystallized by adding 800mL methanol at room temperature for 1 hour to obtain a large amount of brownish-red p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com