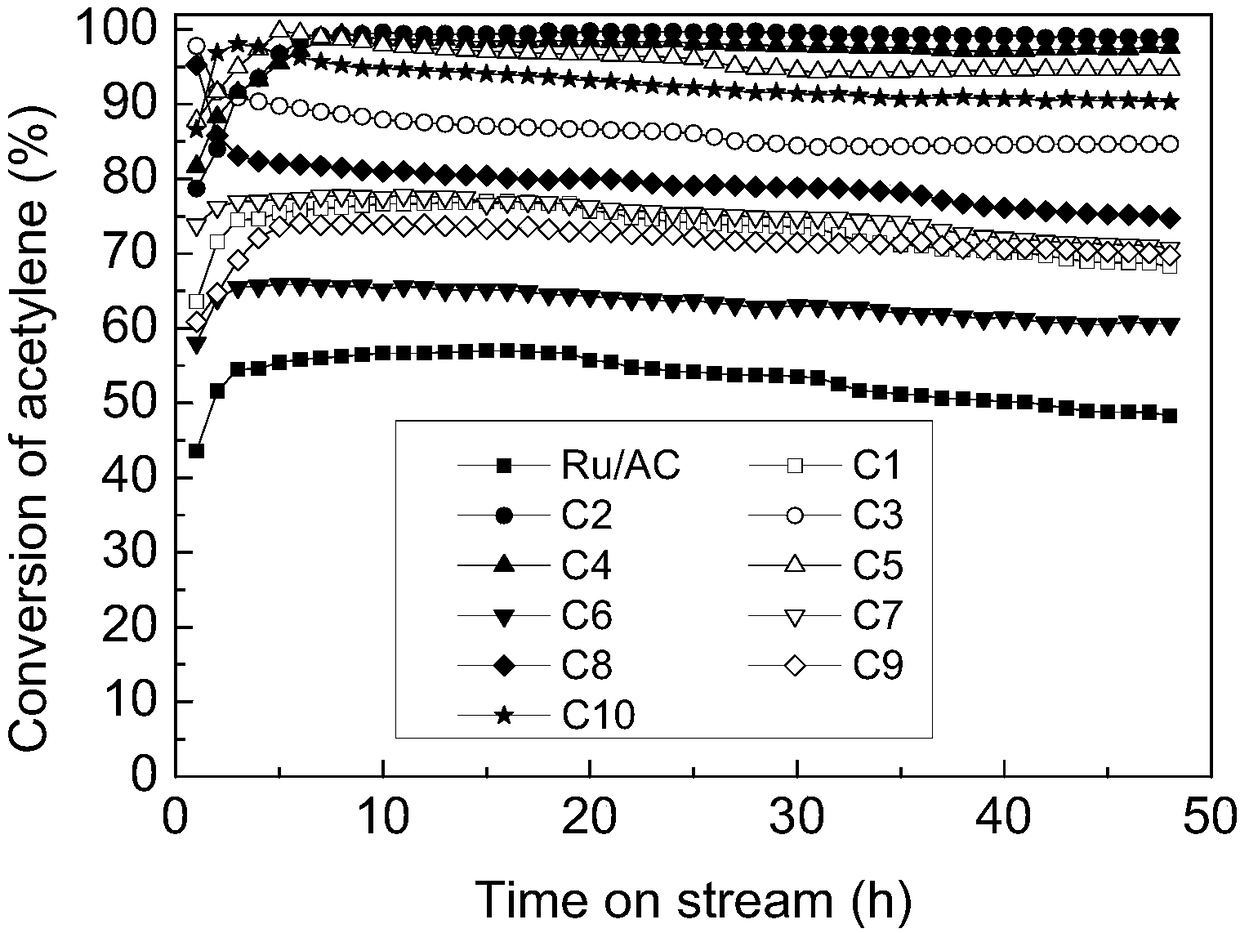

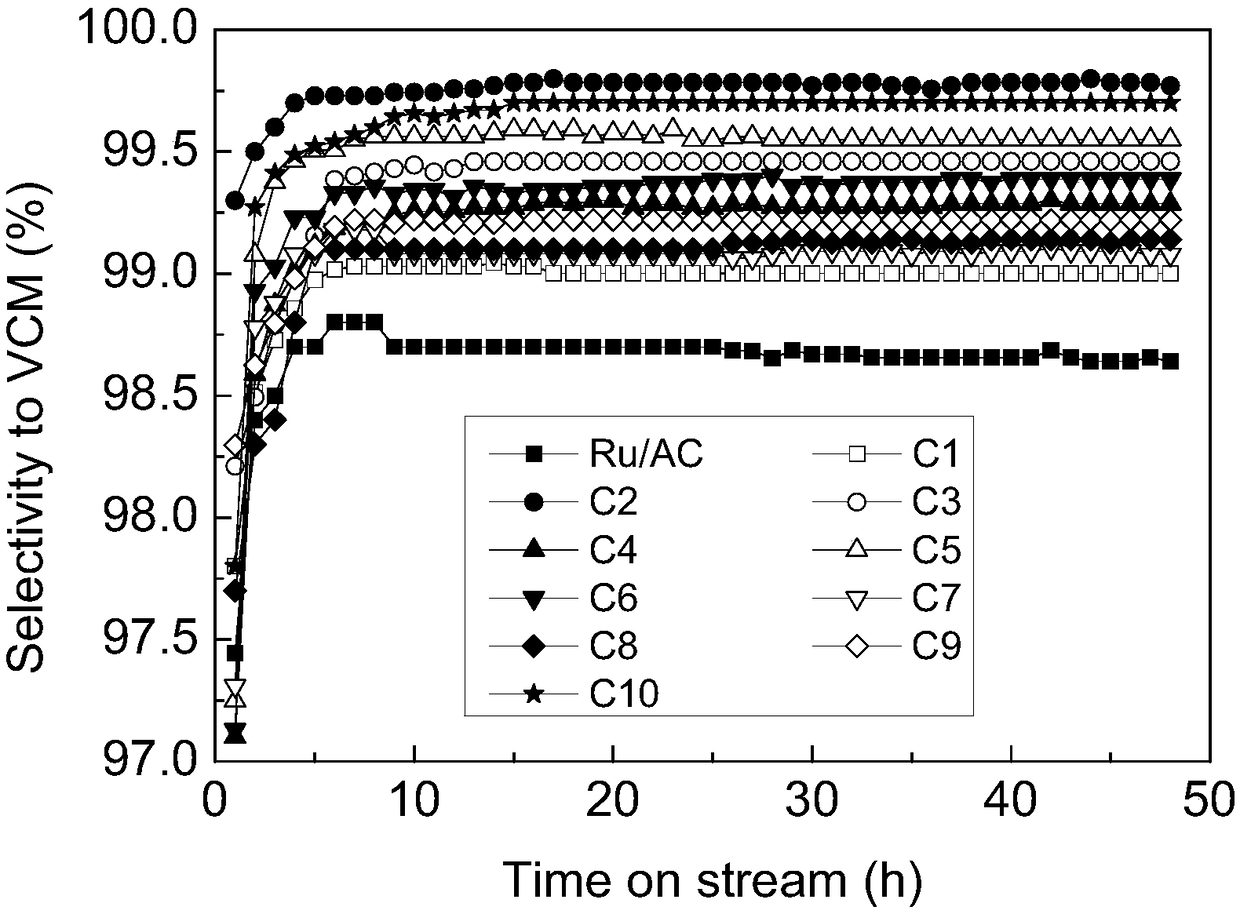

Ruthenium complex catalyzer for acetylene hydrochlorinate and preparation method and application thereof

A technology of acetylene hydrochlorination and ruthenium complexes, applied in the directions of organic compound/hydride/coordination complex catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve unfavorable acetylene hydrochlorination activity, dispersion It can improve the catalytic activity and stability, good dispersibility, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of a highly efficient ruthenium complex catalyst for acetylene hydrochlorination:

[0022] Step 1, preparation of modified activated carbon: take 3g activated carbon (AC), join in the concentrated hydrochloric acid of 12mol / L of 100ml, after stirring at room temperature for 24h, suction filter and wash pH to 5 with deionized water, then process The good activated carbon was dried at 100°C for 24 hours to obtain a modified activated carbon carrier.

[0023] Step 2, preparation of high-efficiency Ru complex catalyst: place the modified activated carbon obtained in step 1 in a sealed suction filter bottle and vacuumize it for 1h, then weigh 0.4651g of RuCl 3 and 1.0641g of organic ligand pyridine (the molar ratio of pyridine to Ru is 6:1), completely dissolve it with 100ml of water, add it to the vacuum-treated activated carbon, stop vacuuming, stir at room temperature for 4h to obtain solid-liquid The mixture is dried at 100° C. for 24 hours to obtain a highl...

Embodiment 2

[0026] Preparation of a highly efficient ruthenium complex catalyst for acetylene hydrochlorination:

[0027] Step 1. Preparation of modified activated carbon: Weigh 3g of activated carbon (AC), add it to 100ml of 5mol / L nitric acid, stir at 80°C for 4h, filter it with suction and wash the pH to 7 with deionized water, then process The good activated carbon was dried at 160°C for 4 hours to obtain a modified activated carbon carrier.

[0028] Step 2, preparation of high-efficiency Ru complex catalyst: place the modified activated carbon obtained in step 1 in a sealed suction filter bottle and vacuumize for 4h, then weigh 0.0685g of RuCl 3 And 0.25986g of organic ligand triphenylphosphine (the molar ratio of triphenylphosphine to Ru is 3:1), it is completely dissolved with 300ml ethanol, joins in the activated carbon of vacuum treatment, and stops vacuuming, at room temperature Stirring at low temperature for 48 hours to obtain a solid-liquid mixture, and drying the obtained m...

Embodiment 3

[0031] Preparation of a highly efficient ruthenium complex catalyst for acetylene hydrochlorination:

[0032] Step 1, prepare modified activated carbon: take 3g activated carbon (AC), add respectively in the nitric acid of 5mol / L of 100ml, after stirring at room temperature for 24h, suction filter and wash pH to 7 with deionized water, then process The good activated carbon was dried at 140°C for 24 hours to obtain a modified activated carbon carrier.

[0033] Step 2, preparation of high-efficiency Ru complex catalyst: place the modified activated carbon obtained in step 1 in a sealed suction filter bottle and vacuumize it for 2 hours, then weigh 0.06604g of RuCl 3and 0.14918g of organic ligand 2,2'-bipyridine (the molar ratio of 2,2'-bipyridine to Ru is 3:1), dissolve it completely with 300ml of n-propanol, and add it to the vacuum-treated activated carbon , and stop vacuuming, stirred at room temperature for 12 hours to obtain a solid-liquid mixture, and dried the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com