Method capable of improving instant dissolving performance of soybean milk powder

A soymilk powder and instant technology, applied in milk substitutes, dairy products, applications, etc., can solve the problems of inability to disperse, sink, dissolve, inability to dissolve soybean powder, and poor instant solubility, so as to improve instant solubility and particle size , Improve the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

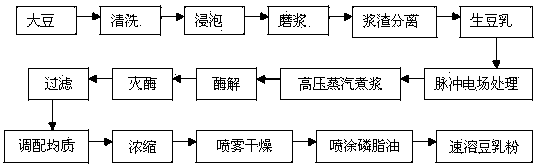

Image

Examples

Embodiment 1

[0020] Wash fresh soybeans with 0.5% NH 4 HCO 3 Soak the soybeans in an aqueous solution for about 10 hours, add weak alkaline water with a pH of 6.5-7.0 at 90°C at a ratio of 1:7 to the soybean water for refining, and then separate the pulp and slag to obtain raw soybean milk. Under the pulse intensity of 30kV / cm, conduct pulse electric field treatment for 288μs, then add 0.5% soybean lecithin oil, and conduct high-pressure steam cooking at 110°C to obtain cooked soybean milk, add 0.2% citric acid to the cooked soybean milk, The temperature is 60°C, the pH of enzymatic hydrolysis is 8.5, add 0.3% Protex-6L alkaline protease to carry out enzymatic hydrolysis for 1.5h, after enzymatic hydrolysis, 95°C to inactivate the enzyme for 15min, then filter to remove insoluble matter, add to the filtered soybean milk 0.2% vitamin E is blended and homogenized under a pressure of 20 MPa. After homogenization, vacuum concentration is carried out until the solid content of soybean milk rea...

Embodiment 2

[0022] Wash fresh soybeans with 0.5% NH 4 HCO 3 Soak the soybeans in an aqueous solution for about 10 hours, add weak alkaline water with a pH of 6.5-7.0 at 90°C at a ratio of 1:7 to the soybean water for refining, and then separate the pulp and slag to obtain raw soybean milk. Under the pulse intensity of 35kV / cm, conduct pulse electric field treatment for 547μs, then add 0.5% soybean lecithin oil, and conduct high-pressure steam cooking at 110°C to obtain cooked soybean milk, add 0.2% citric acid to the cooked soybean milk, The temperature is 60°C, the pH of enzymatic hydrolysis is 8.5, add 0.3% Protex-6L alkaline protease to carry out enzymatic hydrolysis for 1.5h, after enzymatic hydrolysis, 95°C to inactivate the enzyme for 15min, then filter to remove insoluble matter, add to the filtered soybean milk 0.3% vitamin E is blended and homogenized under a pressure of 20 MPa. After homogenization, vacuum concentration is carried out until the solid content of soybean milk rea...

Embodiment 3

[0024] Wash fresh soybeans with 0.5% NH 4 HCO 3 Soak the soybeans in an aqueous solution for about 10 hours, add weak alkaline water with a pH of 6.5-7.0 at 90°C at a ratio of 1:7 to the soybean water for refining, and then separate the pulp and slag to obtain raw soybean milk. Under the pulse intensity of 30kV / cm, conduct pulse electric field treatment for 288μs, then add 0.5% soybean lecithin oil, and conduct high-pressure steam cooking at 110°C to obtain cooked soybean milk, add 0.2% citric acid to the cooked soybean milk, The temperature is 55°C, the pH of the enzymatic hydrolysis is 9, add 0.2% Protex-6L alkaline protease for 1 hour, inactivate the enzyme at 95°C for 15 minutes after enzymolysis, then filter to remove insoluble matter, add 0.1 % Vitamin E is prepared and mixed, homogenized under a pressure of 20MPa, and vacuum concentrated after homogenization until the solid content of soybean milk reaches about 15%. After concentration, it is spray-dried and sprayed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com