Method for preparing ZnO nano rod

A technology of nanorods and zinc nitrate hexahydrate, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex process, expensive equipment and instruments, poor repeatability, etc., achieve simple process equipment, reduce preparation cost, The effect of a short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

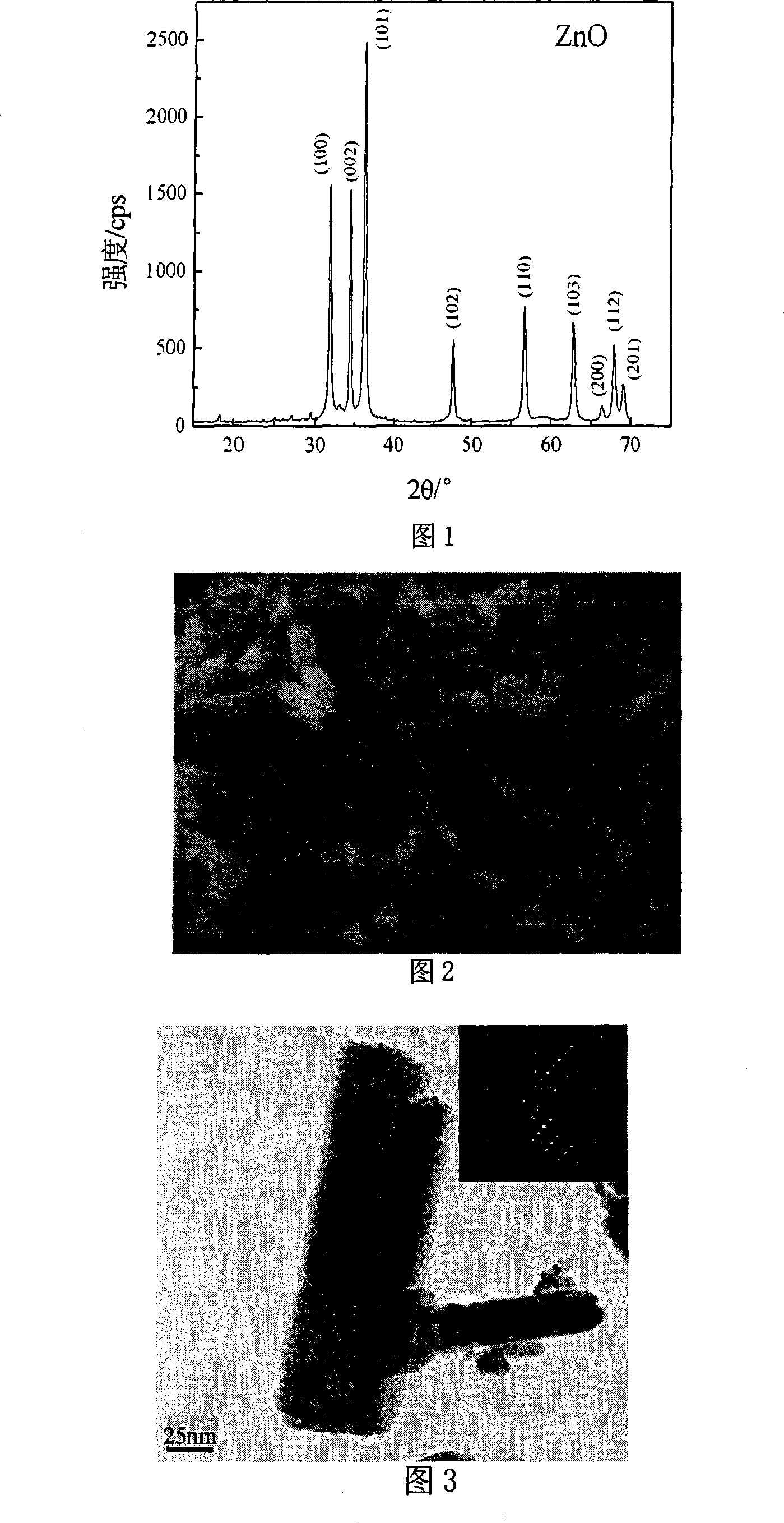

[0013] Embodiment 1, at first analytically pure zinc nitrate hexahydrate (Zn(NO 3 ) 3 ·6H 2 O) add in distilled water, stir, be mixed with Zn 2+ Concentration is the zinc nitrate transparent solution of 0.6mol / L; Add analytically pure sodium hydroxide (NaOH) in the zinc nitrate transparent solution, make the molar concentration ratio in the solution be Zn 2+ / OH - = 1:2, and keep stirring to form a precursor solution; pour the precursor solution prepared above into the hydrothermal reaction kettle, and the filling degree is controlled at 70%; then seal the hydrothermal reaction kettle and put it into MDS-6 Type temperature and pressure double control microwave hydrothermal reactor; select the temperature control mode to react, the hydrothermal temperature is controlled at 160 ° C, the reaction time is controlled at 20 minutes, and the reaction is naturally cooled to room temperature after the reaction is completed; the hydrothermal reaction kettle is opened, and the product...

Embodiment 2

[0015] Embodiment 2, at first analytically pure zinc nitrate hexahydrate (Zn(NO 3 ) 3 ·6H 2 O) add in distilled water, stir, be mixed with Zn 2+ Concentration is the zinc nitrate transparent solution of 0.8mol / L; Add analytically pure urea (CO(NH 2 ) 2 ), so that the molar concentration ratio in the solution is Zn 2+ / urea=1:2, and keep stirring to form a precursor solution; pour the precursor solution prepared above into the hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the hydrothermal reaction kettle and put it into the MDS -6 type temperature-pressure dual-control microwave hydrothermal reactor; choose the temperature control mode to react, the hydrothermal temperature is controlled at 180°C, the reaction time is controlled at 10min, and naturally cool to room temperature after the reaction; open the hydrothermal reaction kettle, the product Collected by filtration, then washed several times with deionized water and anhydrous iso...

Embodiment 3

[0016] Embodiment 3, at first analytically pure zinc nitrate hexahydrate (Zn(NO 3 ) 3 ·6H 2 O) add in distilled water, stir, be mixed with Zn 2+ Concentration is the zinc nitrate transparent solution of 1.0mol / L; Add analytically pure sodium hydroxide (NaOH) in the zinc nitrate transparent solution, make the molar concentration ratio in the solution be Zn 2+ / OH - = 1:2, and keep stirring to form a precursor solution; pour the precursor solution prepared above into the hydrothermal reaction kettle, and the filling degree is controlled at 80%; then seal the hydrothermal reaction kettle and put it into MDS-6 Type temperature-pressure double-control microwave hydrothermal reactor; select the temperature control mode to react, the hydrothermal temperature is controlled at 100 ° C, the reaction time is controlled at 60 minutes, and the reaction is naturally cooled to room temperature after the reaction is completed; the hydrothermal reaction kettle is opened, and the product is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com