Multi-cavity composite micro/nano capsule and preparation method and device thereof

A nanocapsule and nanosphere technology, which is applied in the preparation and application of micro-nano materials, can solve the problem that composite particles do not have core-shell structure and sub-cavity structure, it is difficult to avoid mutual diffusion, mutual reaction, and it is not suitable for precise control of processing and preparation, etc. problem, to achieve the effect of independent coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

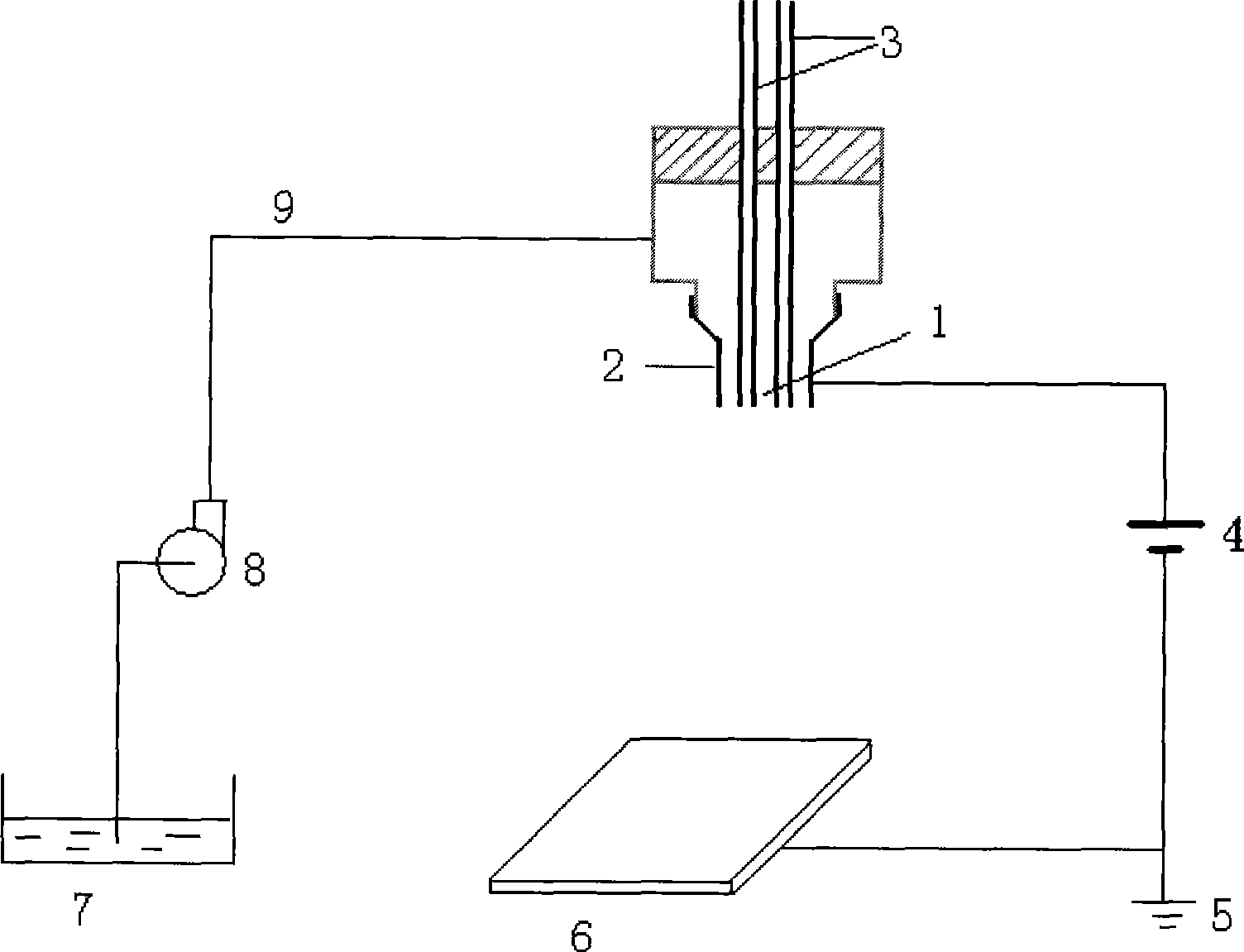

[0062] See figure 1 . use as figure 1 The shown device prepares multi-cavity composite micro / nanocapsules, and the device is composed of an outer nozzle 2 and two inner nozzles 3. A multi-fluid composite nozzle 1, a high-voltage electrostatic generator 4, a ground wire 5, and a static flat metal plate ( or coagulation bath) as a collection plate 6, a liquid storage tank 7, a liquid supply pump 8, an infusion pipeline 9 and the like.

[0063] The outer fluid contained in the liquid storage tank 7 is delivered to the outer spray pipe 2 at a certain flow rate through the liquid supply pump 8 and the infusion tube 9; similarly, the inner fluid is delivered to the inner spray tube at a certain flow rate through the liquid supply pump and the infusion tube. Tube 3; the inner and outer fluids meet at the nozzle of the composite nozzle to form a composite fluid. The inner and outer nozzles are made of metal materials and connected to the positive pole of the high-voltage electrosta...

Embodiment 2

[0067] The device of Example 1 was used.

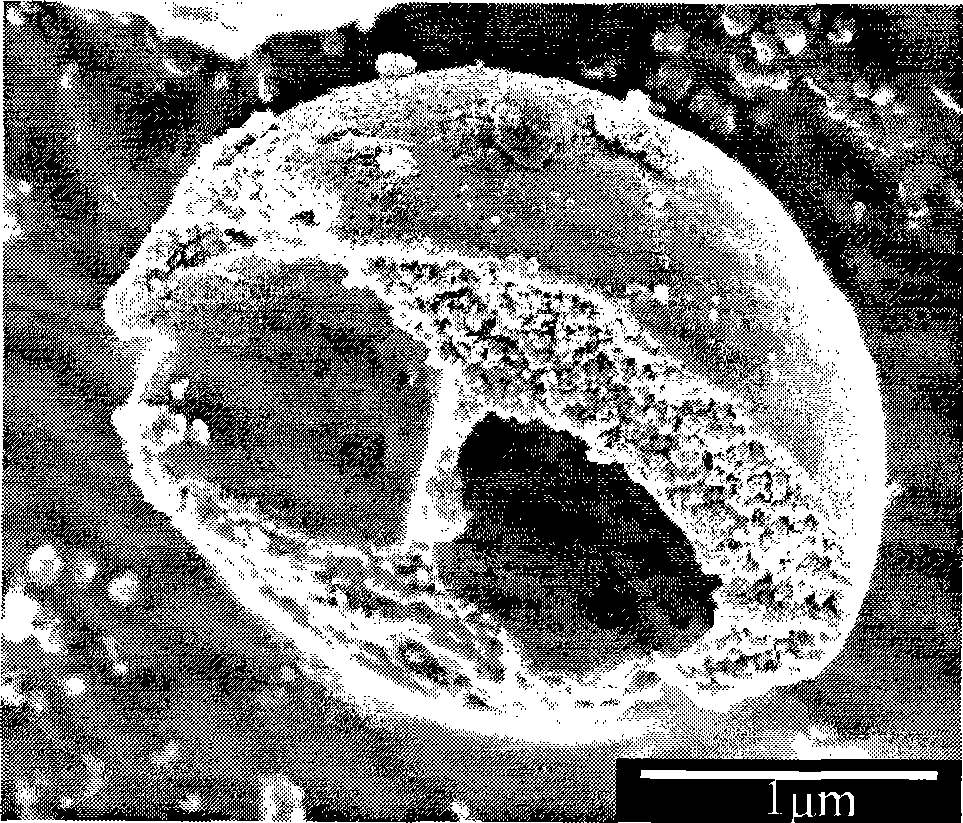

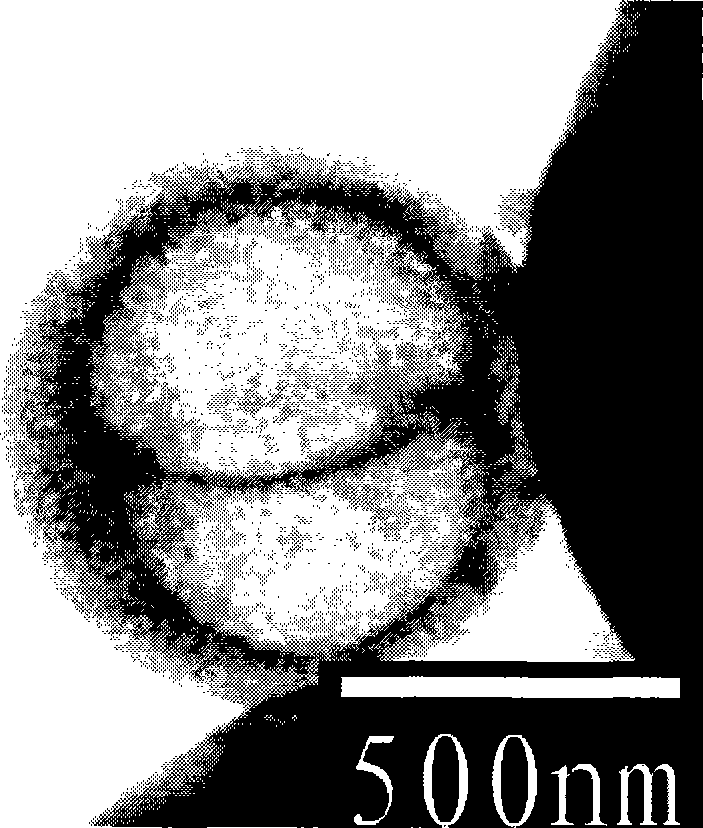

[0068] 2.0 g of polycaprolactone was dissolved in 8 g of chloroform and ethanol mixture (2 / 1, w / w) as the external fluid. The external fluid is passed through the liquid supply pump and the infusion tube at a rate of 1.0-5.0mL·h -1 The velocity is delivered to the outer nozzle. Dissolve 2.5g polyethylene glycol in 6.5g deionized water, then add it to 0.1g acetylsalicylic acid in 0.9g ethanol solution as internal fluid 1; dissolve 2.5g polyethylene glycol in 7.4g deionized Add 0.1g of penicillin to the water as the internal fluid 2, and inject 0.1-1mL·h through the liquid supply pump and infusion tube -1 The velocity of the inner fluid 1 and the inner fluid 2 are delivered to the two inner nozzles respectively. Composite EFI was performed using the same conditions as described in Example 1. A functional microcapsule with a layer of polycaprolactone as the shell material and two drug components loaded in two cavities can be obtained...

Embodiment 3

[0071] The device of Example 1 was used.

[0072] 2.0 g of polymethyl methacrylate was dissolved in 8.0 g of N,N-dimethylformamide as an external fluid. The external fluid is passed through the liquid supply pump and the infusion tube at a rate of 1.0-5.0mL·h -1 The velocity is delivered to the outer nozzle. Dissolve 0.5mg of rhodamine B in 5g of ethylene glycol as internal fluid 1, and dissolve 0.5mg of fluorescein isothiocyanate in 5g of ethylene glycol as internal fluid 2. h -1 The velocity of the inner fluid 1 and the inner fluid 2 are delivered to the two inner nozzles respectively. The composite nozzle is connected to the positive electrode of the high-voltage electrostatic generator, and the metal plate covered with aluminum foil is grounded and used as a collecting plate. The working voltage is 15-25KV, and the distance between the composite nozzle and the collecting plate is 35cm. After multi-fluid compound electrospraying, the functional microcapsules with polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com