Quantity-controlled transportation tool and using method thereof

A tooling and weight technology, applied in the field of quantity-controlled transportation tooling, can solve the problems of prone to errors, high labor intensity and low accuracy, and achieve the effects of strengthening stability, reducing labor intensity and improving packaging counting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

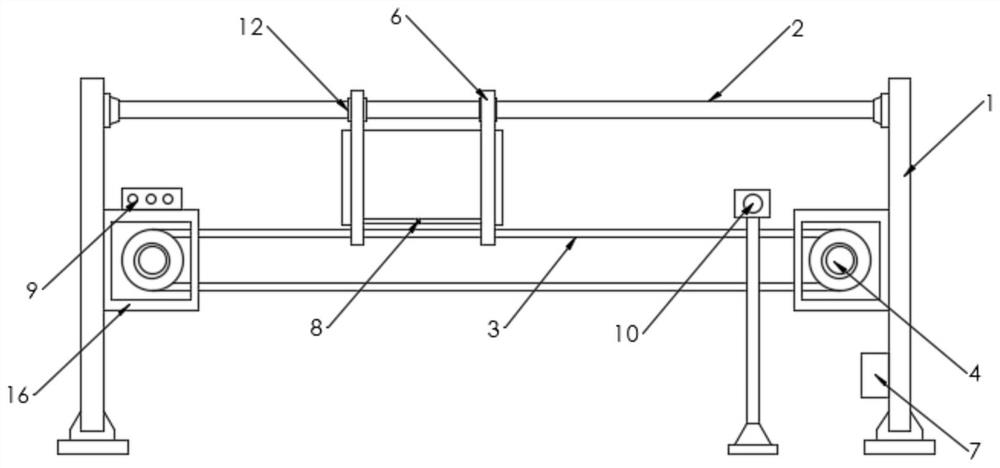

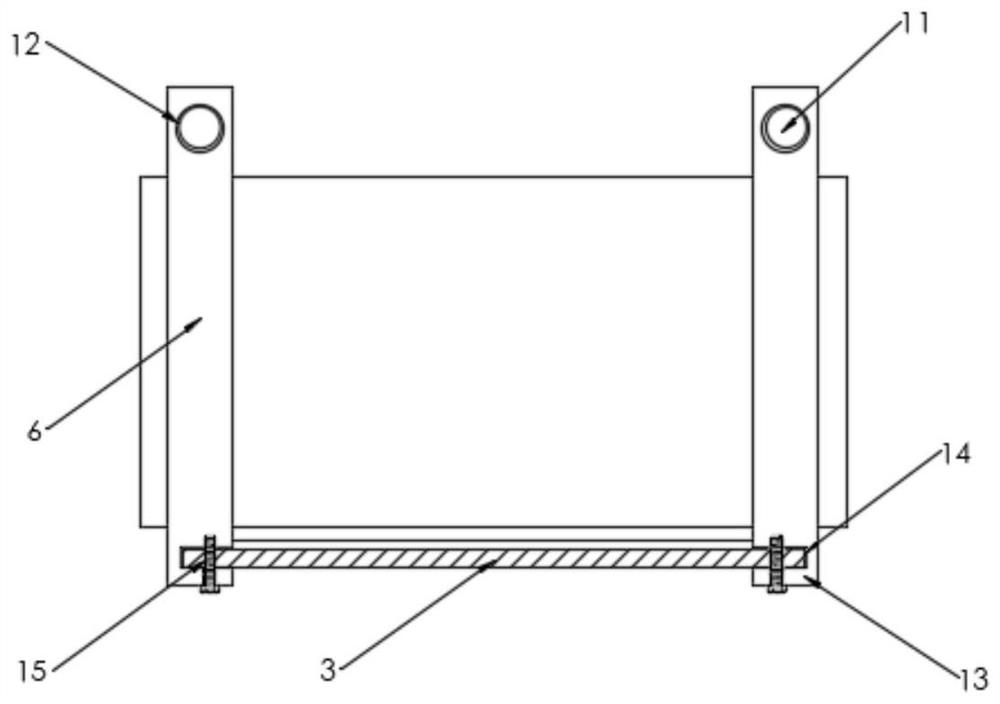

[0034] refer to Figure 1-4 , a quantity-controlled transport tooling comprising

[0035] Two groups of support frames 1, the tops between the two groups of support frames 1 are connected by guide rods 2 arranged side by side in left and right lateral directions;

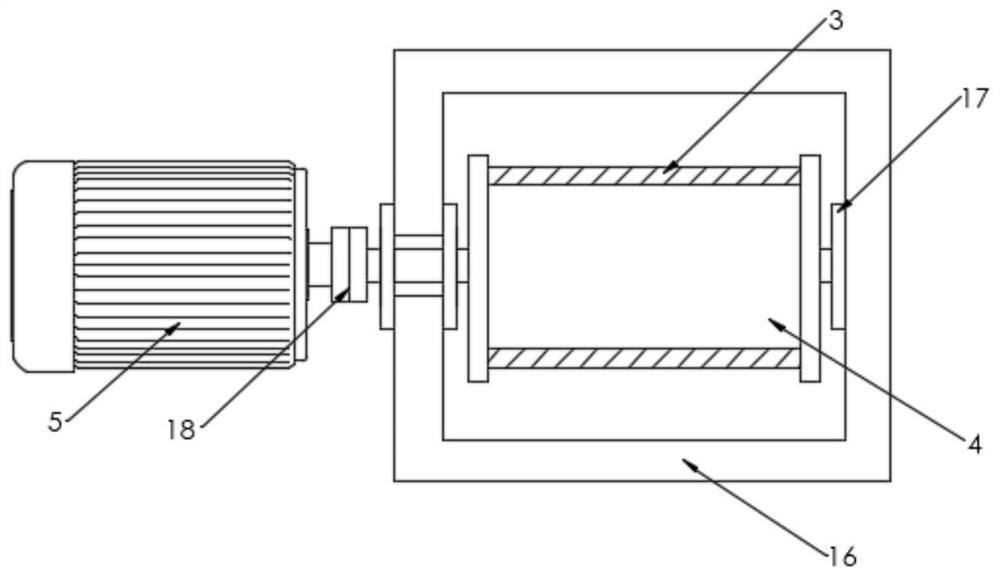

[0036] The transmission mechanism includes a conveyor belt 3 installed directly below the guide rod 2 and corresponding to the guide rod 2. Both ends of the conveyor belt 3 are driven and connected with movable rollers 4, and any movable roller 4 is connected with a Forward and reverse motor 5;

[0037] The conveying frame 6 is installed below the guide rod 2 through the left and right sliding connections at its top, and its bottom end is fixedly installed above the conveying belt 3;

[0038] A control system, used to control the opening and closing actions and the forward and reverse conversion actions of the forward and reverse motor 5, including a control module 7 for controlling the operation of the forward an...

Embodiment 2

[0051] refer to Figure 5 The difference between this embodiment and the first embodiment is that: the control rotation module 10 is an electronic digital counter connected to the forward and reverse rotation motor 5, and the electronic digital counter has a built-in micro switch and a contactor linkage, and moves quantitatively through the conveying frame 6 The number of turns required by the forward and reverse rotation motor 10 when the distance is reached, and then the electronic digital counter is set, that is, the number of rotations of the forward and reverse rotation motor 10 is set.

[0052] The forward and reverse rotation motor 10 rotates for a limited number of turns and stops automatically, and the unloading action is performed manually or externally; the pressure sensor judges whether the weight of the material in the conveying frame 6 is zero, if not, keep the forward and reverse rotation 5 The motor stops until zero. ; Yes, the signal is transmitted to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com