Packaging Structure and Packaging Technology of Lead Frame

A lead frame and packaging structure technology, which is applied to cleaning methods, cleaning methods and utensils using tools, static electricity, etc., can solve the problems of cumbersome, poor heat dissipation, affecting the stability of chip connection points, etc., to achieve heat dissipation and avoid adsorption. The effect of dust and convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments are for illustrative purposes only and are not intended to limit the scope of the present invention.

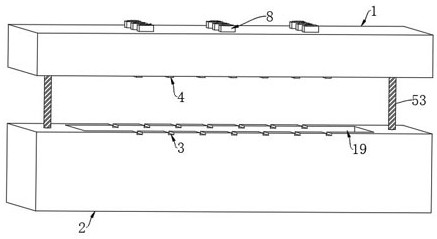

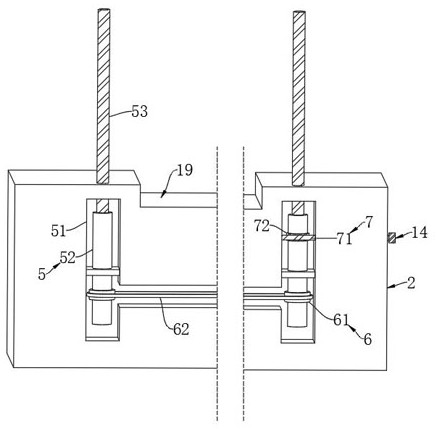

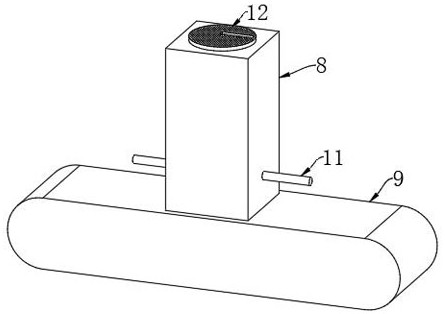

[0027] as Figure 1-6As shown, a lead frame package structure, comprising the upper cover 1 and the lower cover 2, the lower cover 2 is opened with a placement slot 19, and both sides of the lower cover 2 are opened with a plurality of pin slots 3 in line with the placement slot 19, the upper cover 1 is fixedly connected with the pin slot 3 with the briquette 4, the lower cover 2 is provided with two lifting mechanisms 5, and the output end of the two lifting mechanism 5 are fixedly connected with the upper cover 1, the lifting mechanism 5 is composed of a cavity 51, a nut seat 52 and a screw 53, The cavity 51 is opened on the lower seat 2, and the rotation of the nut seat 52 is provided in the cavity 51, the screw 53 is connected with the thread of the nut seat 52 thread, and the upper end of the screw 53 runs through the cavity 51 and is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com