Bundle target coupling sensor

A sensor-target coupling technology, applied in the field of photoelectric sensors, can solve problems such as the inability to guarantee the accuracy and reliability of target shooting, the difficulty of designing and assembling the monitoring system, deformation and scattering, etc., to shorten the laser guidance time, realize visualization, and improve adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

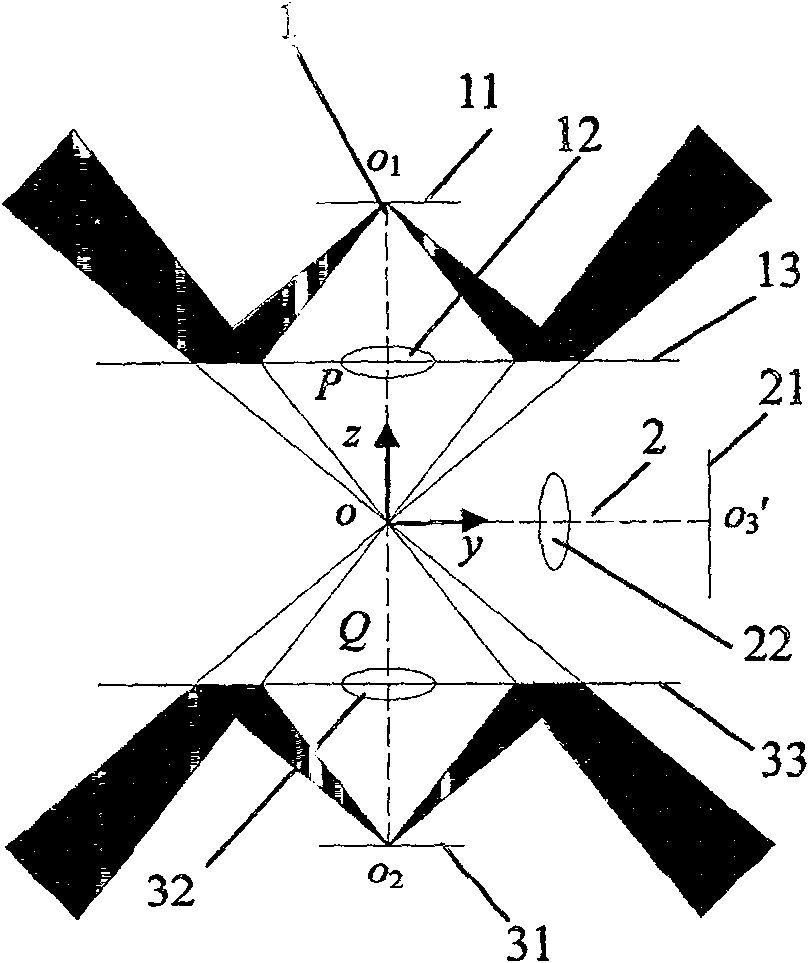

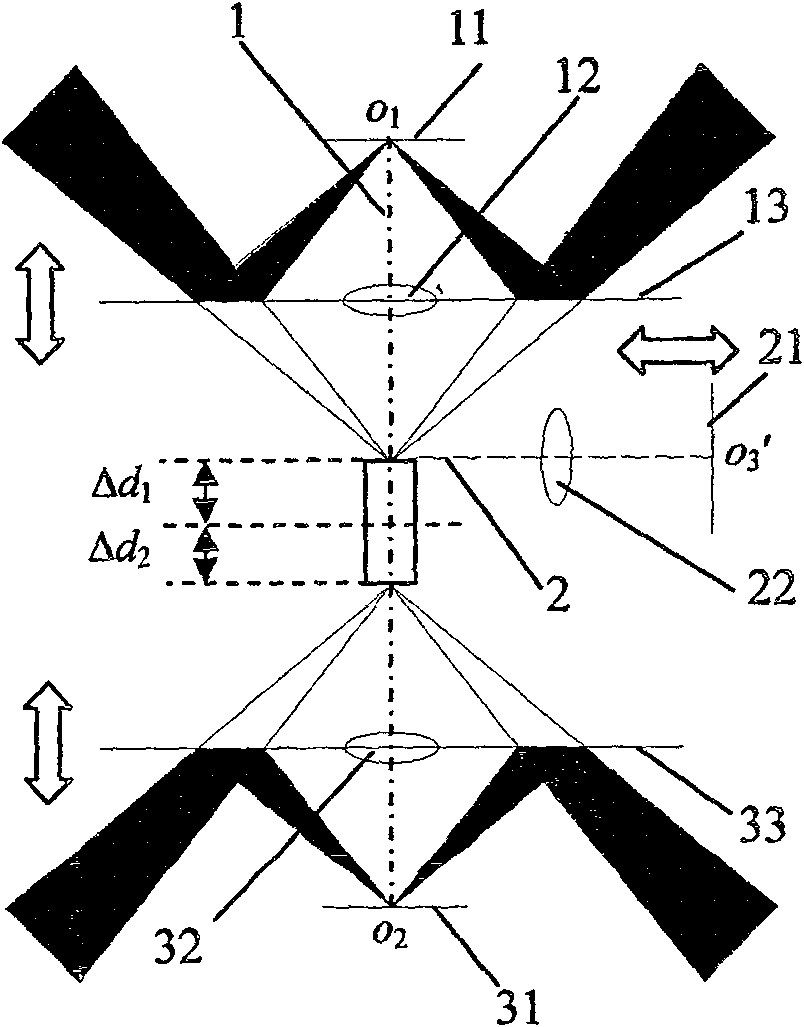

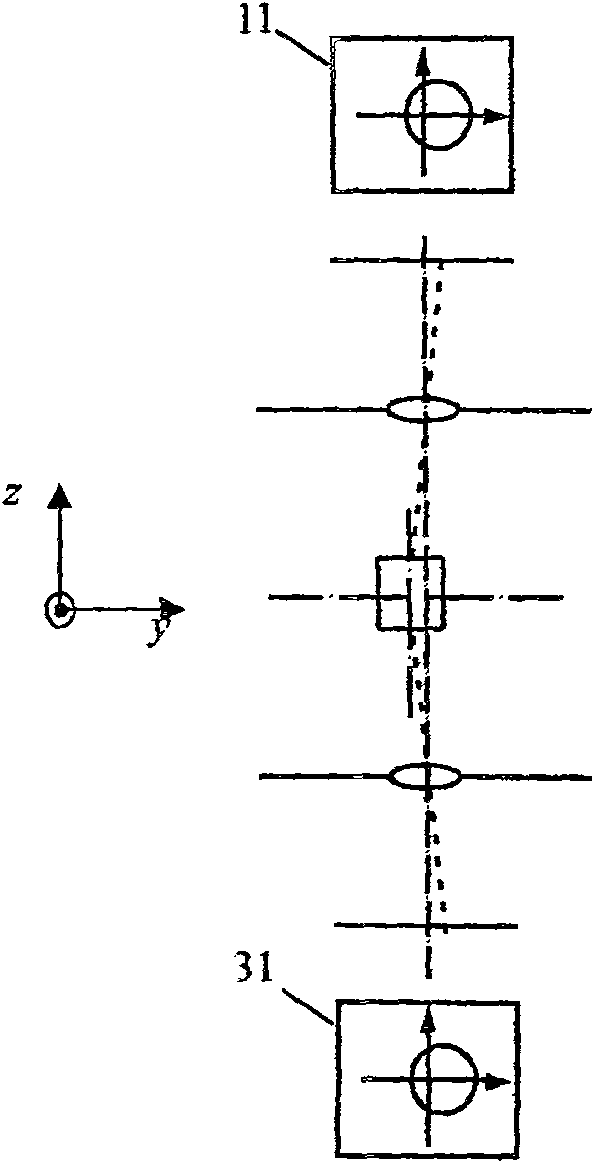

[0018] Specific implementation mode one: combine figure 1 , figure 2 with Figure 6 to Figure 10 Describe this embodiment, the beam-target coupling sensor in this embodiment is composed of an upper monitoring unit, a middle monitoring unit, a lower monitoring unit, and a focusing mechanism;

[0019] The upper monitoring unit is composed of an upper CCD11, an upper microscope objective lens 12, an upper laser reflector 13 and an upper annular LED light source 14;

[0020] There is a circular hole in the middle of the upper laser reflector 13, and the upper microscopic objective lens 12 is fixed on the central position of the circular hole, and the optical axis of the upper microscopic objective lens 12 is perpendicular to the reflection surface of the upper laser reflective mirror 13 , the top of the upper microscopic objective lens 12 is provided with an upper road CCD11, and the upper annular LED light source 14 is installed on the bottom of the upper laser reflector 13. ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 6 to Figure 10 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the upper support frame 41, the lower support frame 42 and the middle monitoring unit support 44 are added; the upper support frame 41, the lower support frame 42 and the middle monitoring unit support 44 are respectively Used to fix the upper monitoring unit, lower monitoring unit and middle monitoring unit. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 6 to Figure 10 Describe this embodiment, the difference between this embodiment and specific embodiment 2 is that the focus adjustment mechanism is composed of an upper focus adjustment mechanism, a lower focus adjustment mechanism, a middle focus adjustment mechanism 53 and a focus adjustment mechanism support frame 43; the upper focus adjustment mechanism is composed of an upload Moving mechanism 511, upper focusing vacuum motor 512 and upper rotating gear 513; The lower rotating gear 523 is composed of: the lower focusing mechanism is used to vertically adjust the position of the lower support frame 42, and the upper focusing vacuum motor 512 and the lower focusing vacuum motor 522 are installed in the focusing mechanism support frame 43; the lower focusing vacuum motor The drive shaft of 522 is connected to the lower rotating gear 523 of the focusing mechanism support frame 43 bottom, and the lower rotating gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com