Metal single atom doped graphene preparation method

A graphene and atom technology, applied in non-metallic elements, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor stability, high cost, low activity, etc., and achieve enhanced adsorption, simple operation, and easy amplification of the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

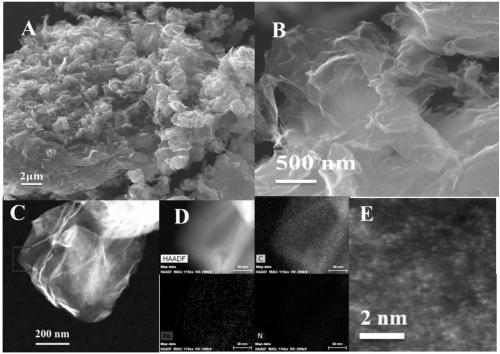

[0035] Take 5 g of urea and 50 mg of ferric nitrate, add 50 ml of water to dissolve it, stir it magnetically for 2 hours and mix well, dry at 80°C for 4 hours, grind uniformly to obtain a red powder, put it in the furnace with argon as protective gas ( The gas flow rate is 200 sccm), the temperature is raised to 300° C. at a heating rate of 10° C. / min, and the heat treatment is performed in an argon atmosphere for 3 hours, and then it is lowered to room temperature to obtain a yellow sample.

[0036] Take 2g of the above yellow sample and 150 mg of functionalized redox graphene (redox graphene has a carbon to oxygen atomic ratio of 4:1, polyvinylpyrrolidone / redox graphene is 2wt%), and mix them thoroughly in an ethanol solution 2 Dry in an oven at 80°C to obtain a gray sample. Put the gray sample into the furnace, use argon as the protective gas (gas flow rate is 300sccm), heat up to 800℃ at a heating rate of 5℃ / min, heat treatment under argon atmosphere for 1 hour, and then lowe...

Embodiment 2

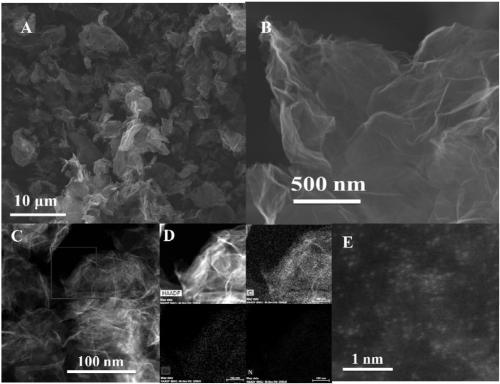

[0040] Take 3 g of melamine and 100 mg of cobalt chloride, add 60 ml of water to dissolve it, stir it magnetically for 2 hours and mix well, dry it at 80°C for 4 hours, grind it evenly to obtain light red powder, put it in the furnace and protect it with argon The temperature was increased to 330°C at a temperature increase rate of 10°C / min, and the temperature was heated to 330°C under argon atmosphere, and then lowered to room temperature to obtain a yellow sample.

[0041] Take 2g of the above yellow sample and 300 mg of functionalized redox graphene (redox graphene has a carbon-to-oxygen ratio of 10:1, polyaniline / redox graphene is 3wt%) and mixed thoroughly in ethanol solution for 2 hours, Dry in an oven at 80°C to obtain a gray sample. Put the gray sample in the furnace, use argon as the protective gas (gas flow rate is 200sccm), heat up to 900°C at a heating rate of 4°C / min, heat treatment at 900°C in an argon atmosphere for 1 hour, and then lower to room temperature. A b...

Embodiment 3

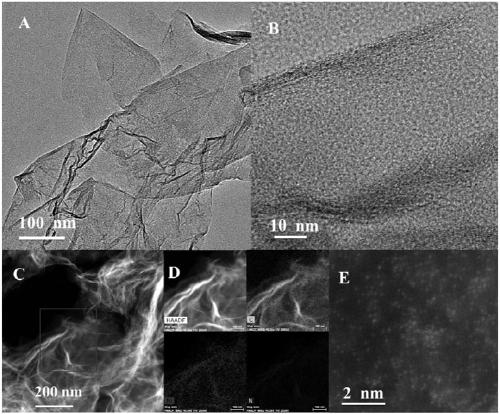

[0045] Take 2 g of dicyandiamide and 20 mg of nickel nitrate, add 60 ml of water to dissolve it, stir it magnetically for 3 hours and mix well, dry it at 80°C for 4 hours, grind it evenly to obtain a light red powder, put it in the furnace with argon With shielding gas (gas flow rate of 300 sccm), the temperature was increased to 360° C. at a temperature increase rate of 10° C. / min, and the heat treatment was performed for 2 hours in an argon atmosphere, and then lowered to room temperature to obtain a yellow sample.

[0046] Take 2g of the above yellow sample and 300mg of polyaziridine (PEI) functionalized nitrogen-doped graphene (nitrogen-doped graphene contains 7wt% nitrogen and PEI / nitrogen-doped graphene is 3wt%) in ethanol The solution was mixed thoroughly for 1 hour and dried in an oven at 80°C to obtain a gray sample. Put the gray sample into the furnace, use argon as the protective gas (gas flow rate is 300sccm), heat up to 850°C at a heating rate of 5°C / min, heat treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com