Process technique of high-strength titanium alloy pipes

A processing technology, titanium alloy technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficult to guarantee the quality of extruded tube blanks, unfavorable material properties, low material utilization rate, etc., and achieve high yield , low production cost, bright surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

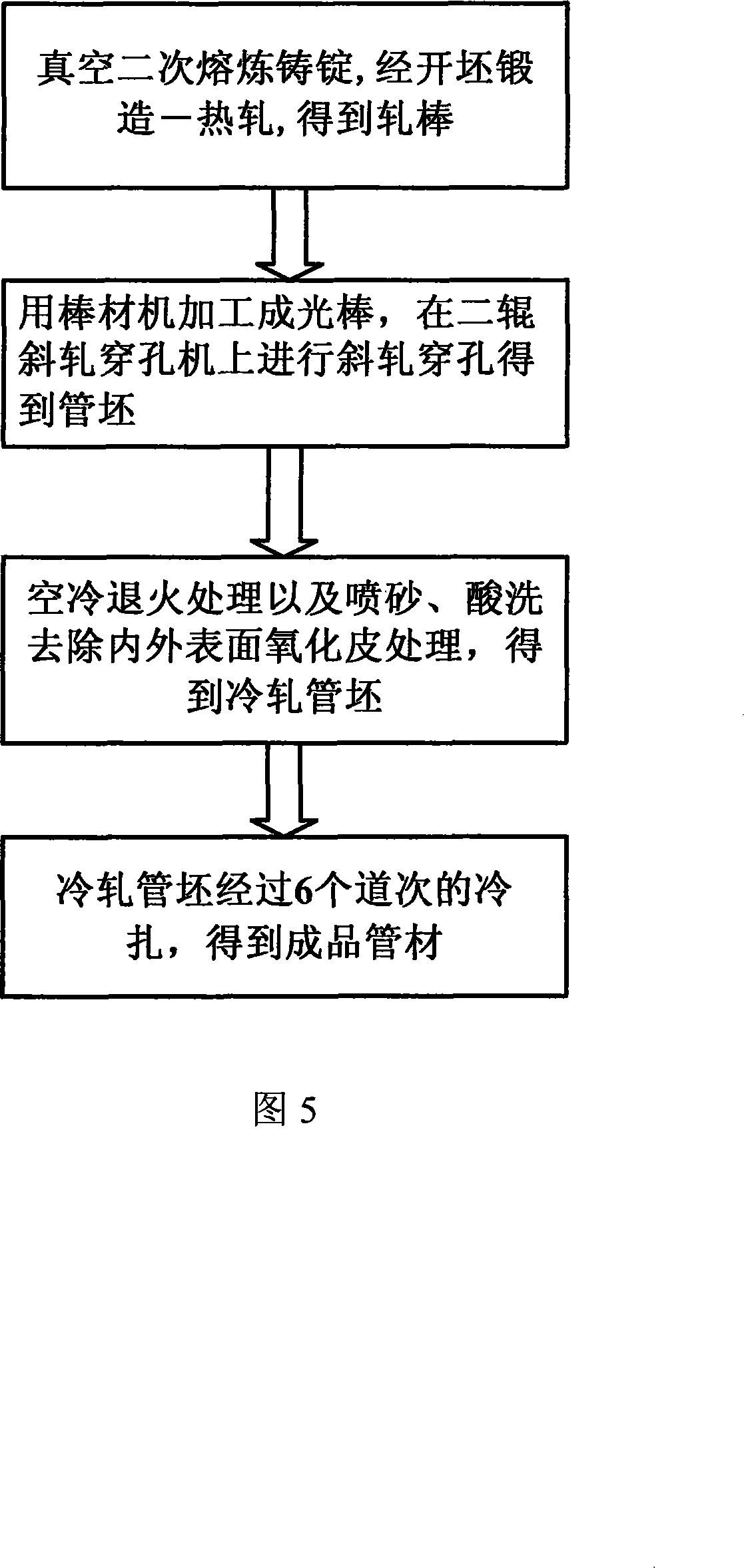

[0016] For the developed TB2 titanium alloy with high room temperature strength and deformation resistance, pipes with an inner diameter of 40-30 mm and a wall thickness of 2-5 mm are processed, and the pipes are processed by cross-rolling, piercing and cold rolling. The specific operation steps are as follows:

[0017] 1) Referring to Figure 1 and Figure 5, the TB2 alloy vacuum secondary melting ingot with a diameter of 380mm is first subjected to two fires at 1150°C and 1110°C for blank forging, and forged into a billet with a cross-section of 120×120mm. Then heat the forged bar to 980°C, keep it warm for 30-50 minutes, and then hot-roll it into a square bar with a cross-section of 55×55mm, and the hot-rolled deformation is 79%;

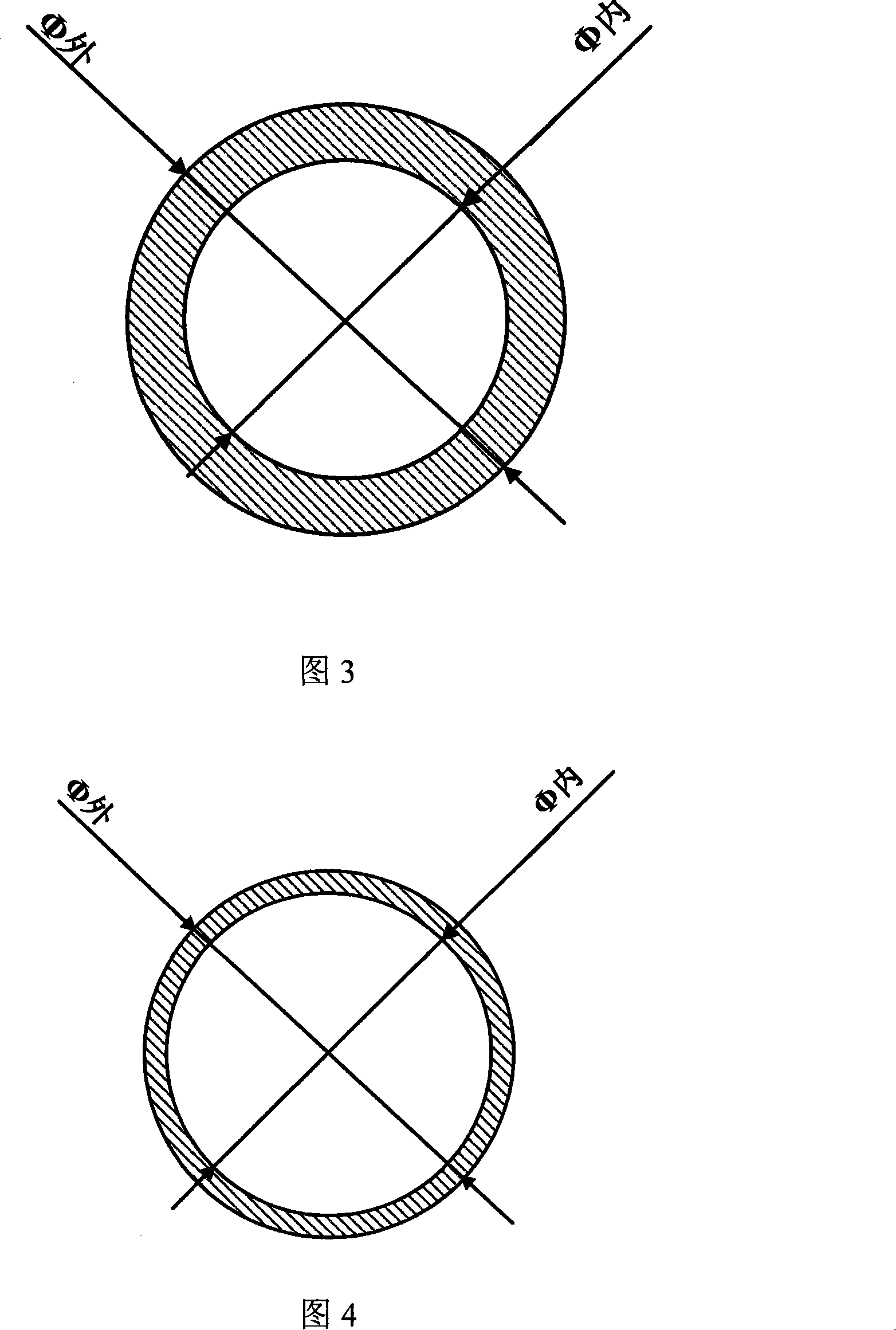

[0018] 2) Referring to Figure 2 and Figure 5, the hot-rolled bar is finished into a φ52×800mm bar, heated to 980°C, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com